Feed for 3D printing as well as preparation method thereof and application thereof

A 3D printing and feeding technology, which is applied in the field of 3D printing feeding and its preparation, can solve the problems of waste of raw materials, insufficient precision, complex and expensive equipment, etc., and achieve the effects of reducing production costs, improving quality, and shortening the development process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

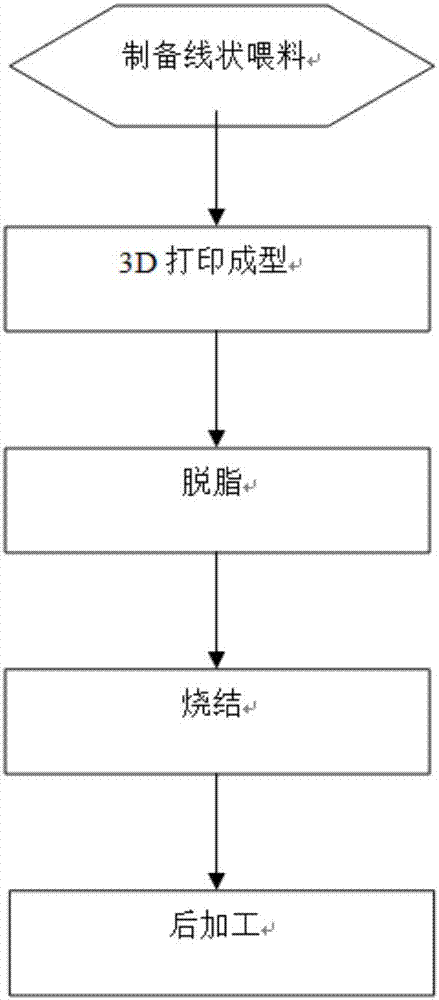

Method used

Image

Examples

Embodiment 1

[0049] A kind of preparation method of feeding material for 3D printing is as follows:

[0050] (1) 60vol% titanium metal powder is mixed with 40vol% polymer binder, and described polymer binder comprises: polyoxymethylene 85wt%, polypropylene 14wt%, stearic acid 1wt%; Add described raw material In an internal mixer, knead at 170°C for 1 hour;

[0051] (2) Utilize extruder to extrude the material obtained after step (1) kneading into a linear material with a diameter of 2 mm, obtain the feed material for 3D printing after cooling, and wind the linear feed material into Disc ready.

[0052] The present embodiment obtains the application of feeding material for 3D printing and comprises the following steps:

[0053] (1) using the linear feed as a raw material, and printing out a green body of a preset shape via a 3D printer;

[0054] (2) degreasing the green body obtained in step (1) at 110° C. using nitric acid as a medium for 4 hours, and removing 10% of the polymer binder ...

Embodiment 2

[0057] A kind of preparation method of feeding material for 3D printing is as follows:

[0058] (1) 50vol% titanium alloy powder is mixed with 50vol% polymer binder, and described polymer binder comprises: paraffin wax 80wt%, polyethylene 19.5wt%, stearic acid 0.5wt%; Described raw material Add to internal mixer, knead at 200°C for 0.5h;

[0059] (2) Utilize extruder to extrude the material obtained after step (1) kneading into a linear material with a diameter of 3 mm, obtain the feed material for 3D printing after cooling, and wind the linear feed material into Disc ready.

[0060] The present embodiment obtains the application of feeding material for 3D printing and comprises the following steps:

[0061] (1) using the linear feed as a raw material, and printing out a green body of a preset shape via a 3D printer;

[0062] (2) Soak the green body obtained in step (1) at 80° C. using n-heptane as a medium for 6 hours, and remove 12% of the polymer binder to obtain a brown...

Embodiment 3

[0066] A kind of preparation method of feeding material for 3D printing is as follows:

[0067] (1) 70vol% copper metal powder is mixed with 30vol% polymer binder, and described polymer binder comprises: paraffin wax 84wt%, polypropylene 14wt%, stearic acid 2wt%; Described raw material is added dense In the mixer, knead at 165°C for 2 hours;

[0068] (2) Utilize extruder to extrude the material obtained after step (1) kneading into a linear material with a diameter of 5mm, obtain the feed material for 3D printing after cooling, and wind the linear feed material into Disc ready.

[0069] The present embodiment obtains the application of feeding material for 3D printing and comprises the following steps:

[0070] (1) using the linear feed as a raw material, and printing out a green body of a preset shape via a 3D printer;

[0071] (2) Soak the green body obtained in step (1) at 60° C. using n-heptane as a medium for 8 hours, and remove 11% of the polymer binder to obtain a br...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com