Running belt finished product or semi-finished product and manufacturing method thereof

A technology for running belts and semi-finished products, which is applied to the manufacturing method of running belts and its products, and can solve the problems of easy corrosion and wear, paint peeling and rusting, and deformation of reinforced woven fabrics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

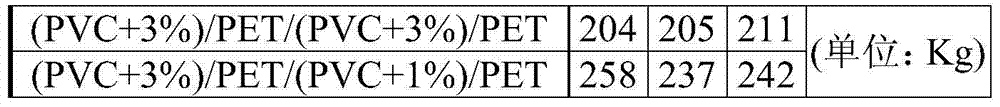

[0017] The running belt is basically a kind of fabric-reinforced composite running belt made of two-layer PET woven fabric impregnated with PVC and then laminated, hot-pressed, dried and formed, slitting, cutting, joining, testing, etc. bring. In view of how to prolong the durability and service life of the running belt, and even surpass commercially available products, the lengthy test results of the 2368-hour dynamic test in the field found that we solved the problem that the temperature of the running belt reached below 80°C under long-term operation. And it is more than 90°C than the commercial running belt products on the market in the past, and the temperature is lowered by more than 10°C. The reason for this functional benefit is that 1% to 5% of secondary substances with functions such as fast heat dissipation, lubrication, and low friction are added to the PVC base material. Micron or nanoscale inorganic powder. However, because the micron or nanoscale inorganic powd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal diffusivity | aaaaa | aaaaa |

| Thermal diffusivity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com