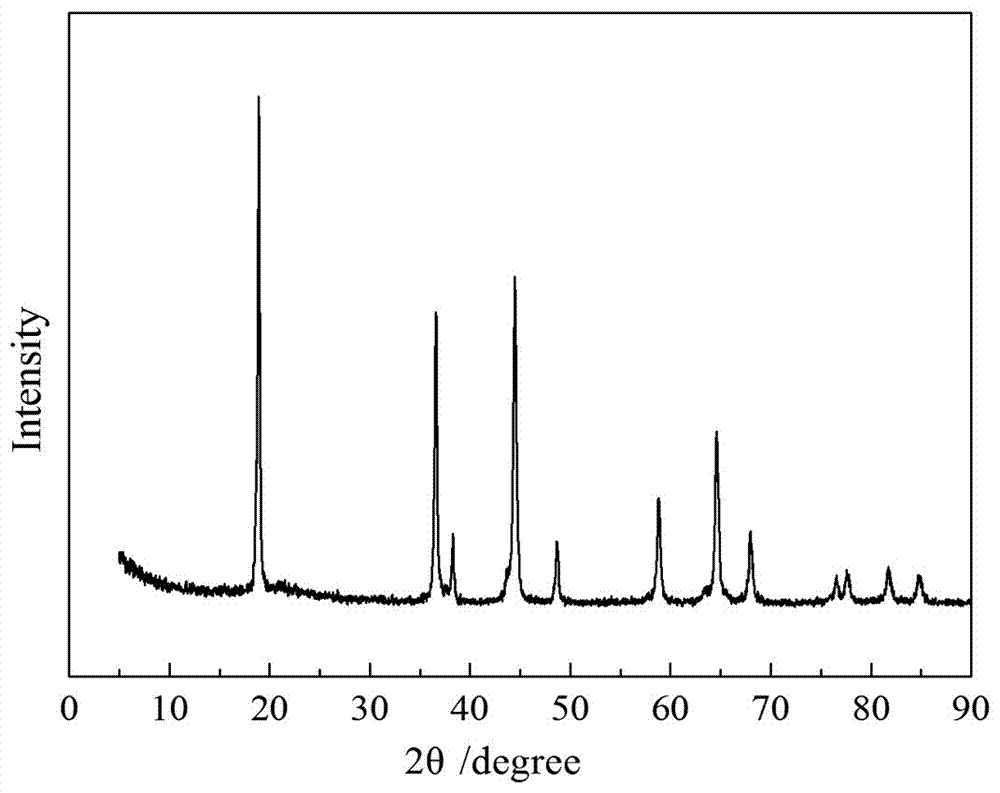

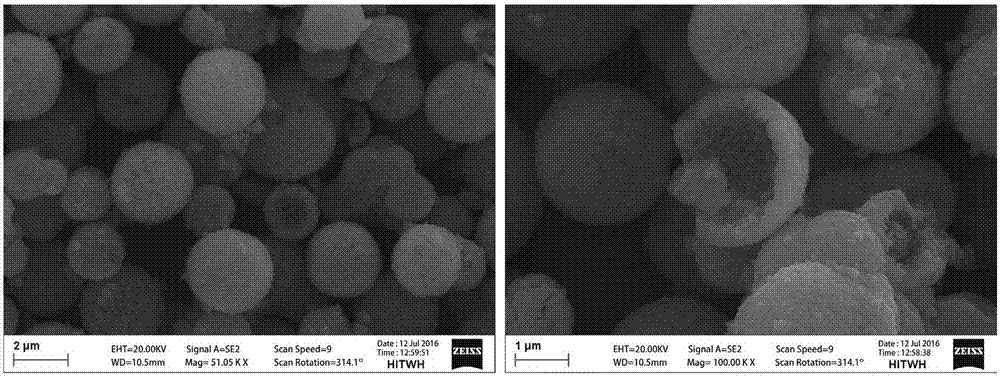

Preparation method of high-voltage lithium ion battery positive electrode material hollow spherical LNMO

A cathode material, lithium nickel manganese oxide technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as unfavorable large-scale production, low yield of hydrothermal reactors, cumbersome synthesis process, etc., and achieve a good cycle. The effect of stability, favorable contact and rich source of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A hollow spherical lithium nickel manganese oxide, a positive electrode material for a high-voltage lithium battery. The preparation steps are as follows:

[0030] (1) Evenly disperse 3.375mmol manganese sulfate and 1.125mmol nickel sulfate in a mixture of 30ml absolute ethanol and 60ml deionized water, and stir for 50min to obtain a dispersion of manganese nickel sulfate;

[0031] (2) Disperse 225mmol of ammonium bicarbonate evenly in 60ml of deionized water and stir for 30min to obtain ammonium bicarbonate solution;

[0032] (3) Slowly add the ammonium bicarbonate solution prepared in (2) dropwise into the mixed solution of (1), and continue to stir for 60 minutes to obtain grass-green nickel-manganese carbonate precipitation;

[0033] (4) Suction filter the above precipitate, and repeatedly wash with deionized water and absolute ethanol three times, collect the precipitate, and dry at 60°C for 5 hours;

[0034] (5) Dissolve 2.362mmol lithium hydroxide in deionized w...

Embodiment 2

[0039] A hollow spherical lithium nickel manganese oxide, a positive electrode material for a high-voltage lithium battery. The preparation steps are as follows:

[0040] (1) Same as embodiment 1

[0041] (2) Same as embodiment 1

[0042] (3) Same as embodiment 1

[0043] (4) Same as embodiment 1

[0044] (5) Dissolve 1.181mmol of lithium carbonate in absolute ethanol, stir the dried precipitate and lithium carbonate solution for 30 minutes, then raise the temperature to 50°C and continue stirring until the ethanol is volatilized, and then place it in blast drying Blast drying in the box;

[0045](6) Heat the dried mixture from room temperature to 400°C at a heating rate of 3°C / min, sinter for 3 hours, then increase the temperature at a rate of 3°C / min to 700°C, sinter for 8 hours, and cool to room temperature naturally. Obtain hollow spherical lithium nickel manganese oxide.

[0046] The hollow spherical lithium nickel manganese oxide prepared by the method is used as th...

Embodiment 3

[0048] A hollow spherical lithium nickel manganese oxide, a positive electrode material for a high-voltage lithium battery. The preparation steps are as follows:

[0049] (1) Evenly disperse 2.25mmol manganese sulfate and 0.75mmol nickel sulfate in a mixture of 10ml absolute ethanol and 20ml deionized water, and stir for 40min to obtain a dispersion of manganese nickel sulfate;

[0050] (2) Disperse 15mmol of ammonium bicarbonate evenly in 20ml of deionized water and stir for 30min to obtain ammonium bicarbonate solution;

[0051] (3) Same as embodiment 1;

[0052] (4) Same as embodiment 1;

[0053] (5) Dissolve 1.575 mmol of lithium acetate in deionized water, stir the dried precipitate and lithium acetate solution for 50 minutes, then raise the temperature to 70°C and continue stirring until the water evaporates, and then place it in a blast drying oven carry out blast drying;

[0054] (6) Heat the dried mixture from room temperature to 500°C at a heating rate of 3°C / min,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com