Air source transcritical CO2 heat pump and multi-melting-point phase change heat storage coupling heating system

A phase change heat storage and heating system technology, applied in hot water central heating systems, heating systems, central heating components, etc., can solve the problem of increased throttling loss, unresolved system stability and reliability, and large throttling loss and other problems to achieve the effect of reducing throttling loss and improving comprehensive utilization performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

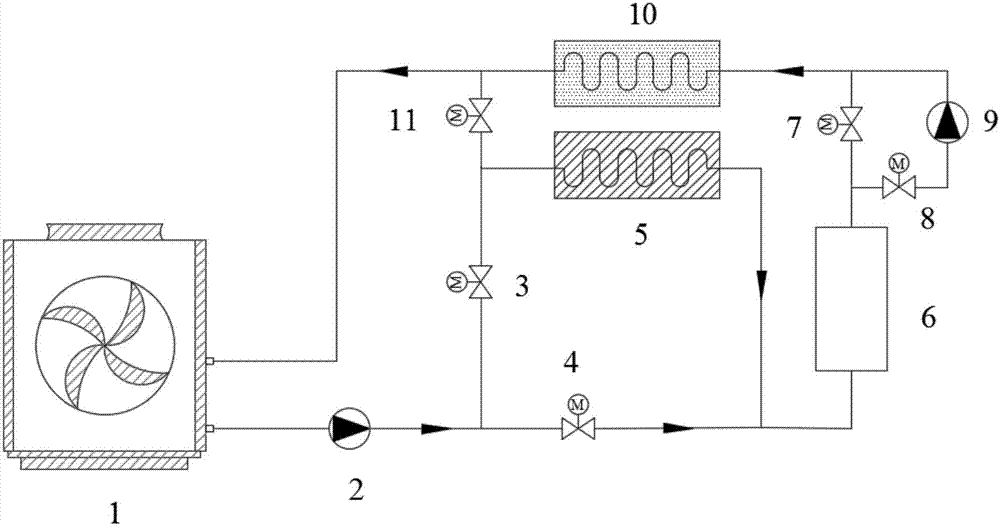

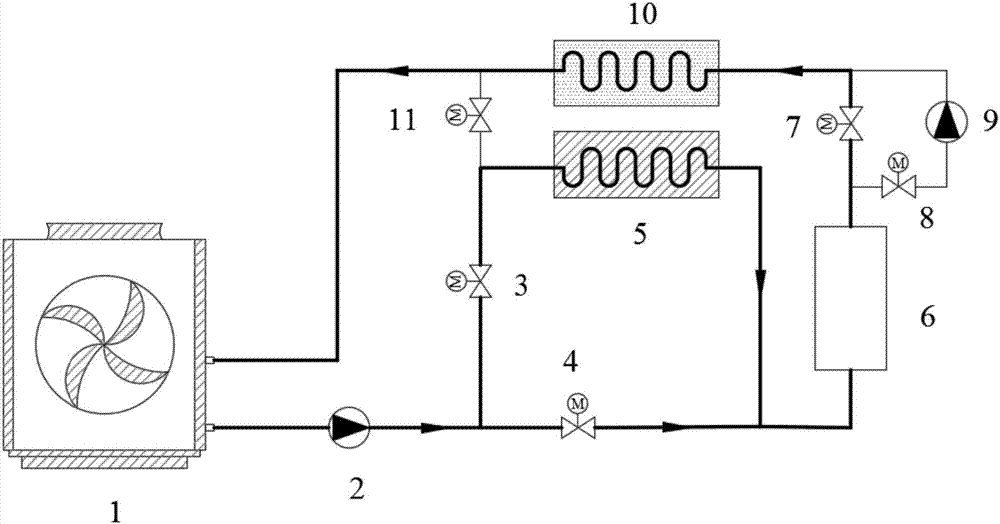

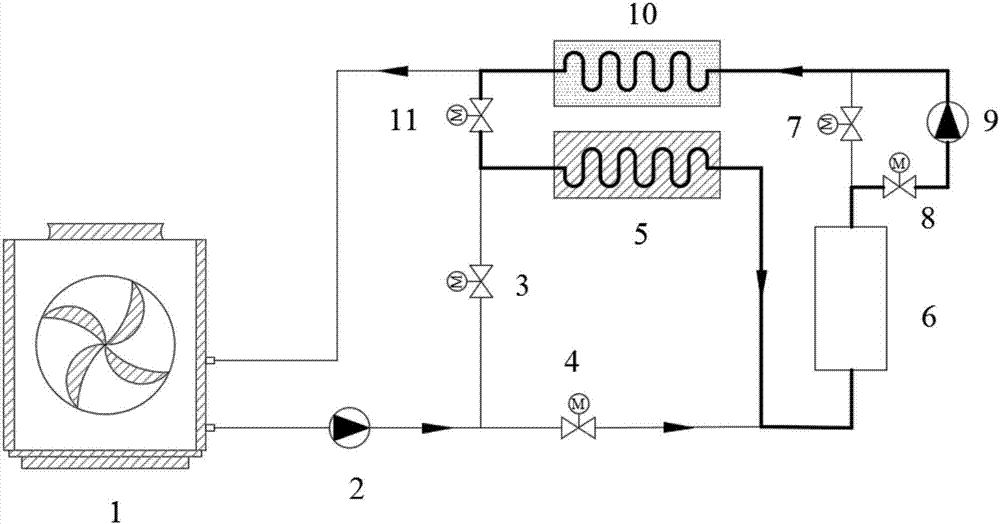

[0025] The present invention will be further described below in conjunction with the drawings.

[0026] See figure 1 , An air source transcritical CO provided by the present invention 2 Heat pump and multi-melting phase change heat storage coupling heating system, including CO 2 Air source heat pump unit 1, CO 2 The outlet of the air source heat pump unit 1 is connected to the first variable-frequency water pump 2, and the outlet of the variable-frequency water pump 2 is divided into two channels, one is connected to the inlet of the high melting point phase change heat storage device 5 through the first solenoid valve 3, and the other is connected through the second solenoid valve 4 The outlet is mixed with the outlet of the high melting point phase change heat storage device 5 and connected to the inlet of the user 6. The outlet of the user 6 is divided into two ways, one is connected to the inlet of the third solenoid valve 7, and the other is connected to the inlet of the fourt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com