Lubricating oil for elevator traction machines and preparation method of lubricating oil

A technology of elevator traction machine and lubricating oil, which is applied in the field of lubricating oil to achieve good anti-friction characteristics, good low-temperature fluidity and thermal oxidation stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

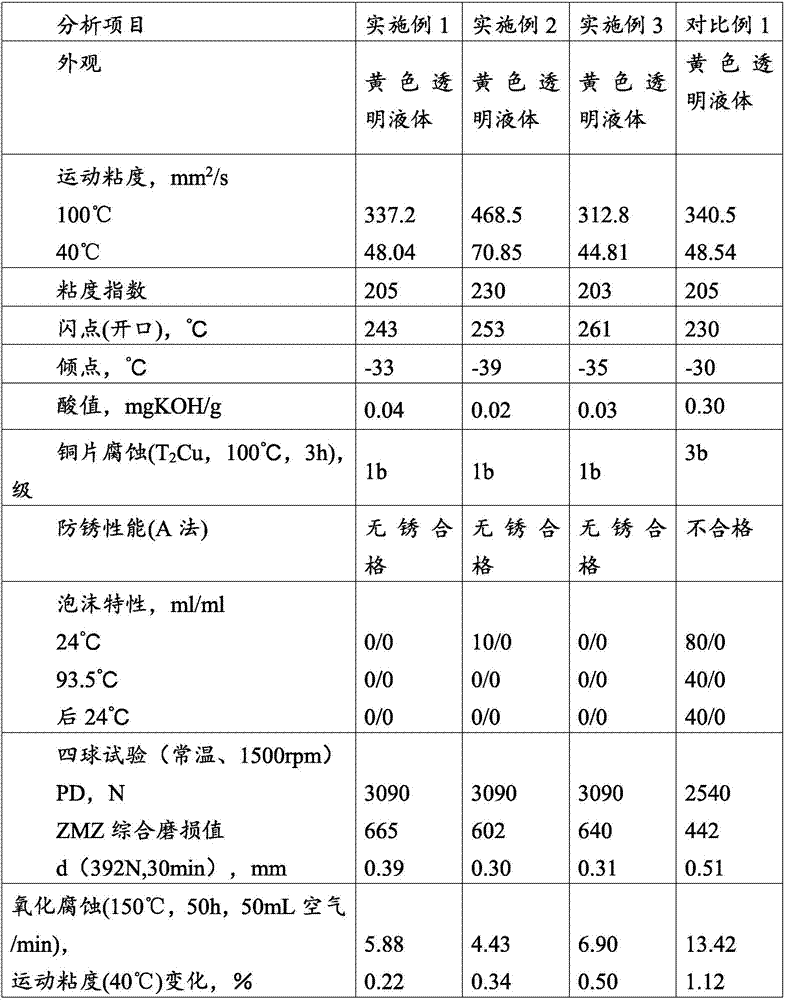

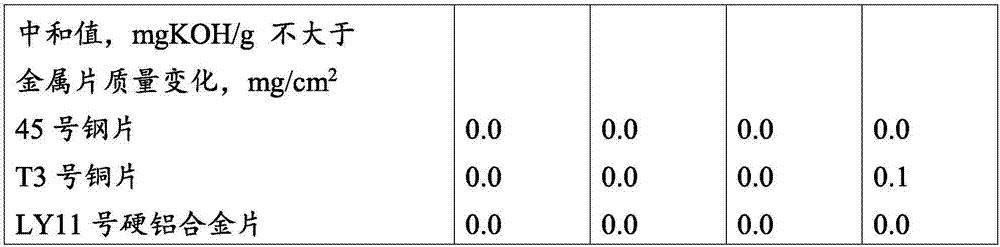

Examples

preparation example Construction

[0039] The present invention also provides a preparation method of lubricating oil for elevator traction machine, comprising:

[0040] Mix and dehydrate 100 parts by weight of PAG base oil, 1-2 parts by weight of antioxidant, 2.0-4.0 parts by weight of extreme pressure anti-wear agent, 1.0-2.0 parts by weight of anti-corrosion agent and 0.005-0.10 part by weight of anti-foaming agent to obtain elevator traction lubricating oil for lead machine;

[0041] Wherein, the antioxidant is obtained by compounding a phenolic antioxidant and an amine antioxidant.

[0042] According to the present invention, 100 parts by weight of PAG base oil, 1-2 parts by weight of antioxidant, 2.0-4.0 parts by weight of extreme pressure anti-wear agent, 1.0-2.0 parts by weight of anti-corrosion agent and 0.005-0.10 part by weight of anti-foaming agent Mixing and dehydration to obtain lubricating oil for elevator traction machine; wherein, the PAG base oil preferably has a kinematic viscosity of 288-35...

Embodiment 1

[0048] Step a) sending 50% by weight of JM-305A and 50% JM-306B into the blending kettle with a gear pump, evacuating, stirring, heating, and heating to 80°C;

[0049] Step b) To the base oil of step a), add 1.0% diisooctyl diphenylamine, 1.0% bisphenol A, 0.3% T706 benzotriazole (T706), 3.0% tricresol phosphate (TCP), 0.8% basic barium dinonylnaphthalene sulfonate (T705), 0.1% 1000# methyl silicone oil antifoaming agent, heat up to 120℃ and dehydrate for 1~2h;

[0050] Step c) Take out a small amount of the oil product obtained in step b), add 0.03% white clay filter aid by weight of all oil products and stir, and carry out cyclic filtration, so that the filter aid forms a filter cake in the filter machine, and then filter the filter in the kettle. The remaining oil is filtered through circulation until the oil is clear and transparent without mechanical impurities, and the lubricating oil for elevator traction machine is obtained.

Embodiment 2

[0052] Step a) The JM-306B with a weight percentage of 100% is sent into the preparation kettle with a gear pump, evacuated, stirred, heated, and heated to 80°C;

[0053] Step b) Add 0.5% benzotriazole dodecylamine, 0.5% antioxidant 1330, 4.0% zinc dialkyldithiophosphate, 0.25% basic dinonylnaphthalene sulfonic acid to the base oil of step a) Barium (T705), 0.75% oleic acid, 0.05% MS-675 modified silicone oil antifoaming agent, heat up to 120°C for dehydration for 1-2h;

[0054] Step c) Take out a small amount of the oil product obtained in step b), add 0.05% of 0.03% of the weight of all oil products and stir, and carry out circulating filtration, so that the filter aid forms a filter cake in the filter machine, and then the remaining oil in the kettle is removed. The lower oil is circulated and filtered until the oil is clear and transparent without mechanical impurities, and the lubricating oil for elevator traction machine is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com