Oleic acid-lanthanum trifluoride-graphene compounded lubricating oil antiwear agent and preparation method thereof

A graphene composite and lanthanum trifluoride technology, which is applied in the field of lubricating oil anti-wear agents, can solve the problems of not being able to fully exert lubrication and anti-wear, and easy agglomeration of nano-lanthanum trifluoride and graphene, and achieve good thermal stability and Effects of chemical stability, good solubility and dispersibility, and excellent stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

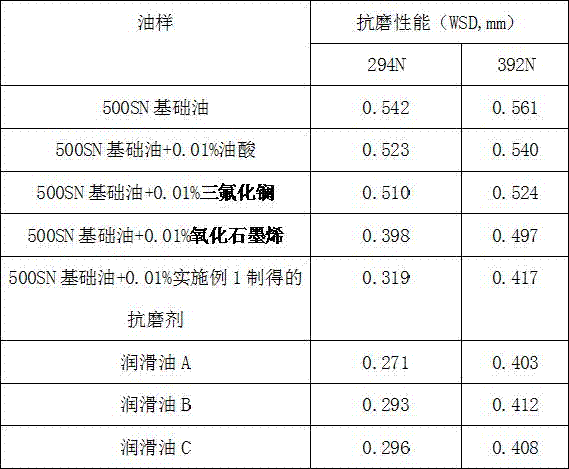

Examples

Embodiment 1

[0022] First, ammonium fluoride (the concentration of ammonium fluoride is 0.62 mol / L) and graphene oxide nanosheets (oligolayer graphene with a sheet diameter of 0.8 μm, and the mass percentage of graphene oxide is 1%) were added to the containing 35% ethanol aqueous solution, then add lanthanum nitrate solution dropwise at 60°C (the concentration of lanthanum nitrate solution is 0.30mol / L), about 2h, 120ml saturated ethanol solution (containing 4ml oleic acid) is added to the flask, After another 3 hours, the product was gradually cooled to room temperature, filtered, washed repeatedly with deionized water and ethanol, and finally dried at 80°C for 12 hours to obtain antiwear agent A;

[0023] Anti-wear agent A was added to the base oil in different mass ratios, and ball milled. At the same time, 0.03% mass ratio of dispersant (boride of succinimide) was added, and 0.02% mass ratio of emulsifier (stearic acid Sodium and saponin emulsifier), the ball milling time is 10 minute...

Embodiment 2

[0025] First, ammonium fluoride (the concentration of ammonium fluoride is 1.20 mol / L) and graphene oxide nanosheets (oligolayer graphene with a sheet diameter of 1 μm, and the mass percentage of graphene oxide is 5%) are added to the ethanol-containing 35% aqueous solution. Then add lanthanum nitrate solution dropwise at 100°C (the concentration of lanthanum nitrate solution is 0.01mol / L), about 3h, 120ml saturated ethanol solution (including 4ml oleic acid) is added into the flask, and after another 3h, wait until the product gradually After cooling to room temperature, filter, wash repeatedly with deionized water and ethanol, and finally dry at 80°C for 12 hours to obtain antiwear agent B;

[0026] Add anti-wear agent B into the base oil in different mass ratios, and perform ball milling. At the same time, 0.03% mass ratio of dispersant (montanic acid ester) and 0.02% mass ratio of emulsifier (sodium stearate and saponin emulsification agent), the ball milling time was 10 ...

Embodiment 3

[0028] First, ammonium fluoride (the concentration of ammonium fluoride is 0.02 mol / L) and graphene oxide nanosheets (oligolayer graphene with a sheet diameter of 0.9 μm, and the mass percentage of graphene oxide is 0.1%) were added to the containing Ethanol 35% aqueous solution, then add lanthanum nitrate solution dropwise at 80°C (the concentration of lanthanum nitrate solution is 0,60mol / L), about 4h, 120ml saturated ethanol solution (including 4ml oleic acid) is added to the flask , after another 3 hours, after the product was gradually cooled to room temperature, it was filtered, washed repeatedly with deionized water and ethanol, and finally dried at 80°C for 12 hours to obtain anti-wear agent C;

[0029] Add anti-wear agent C to the base oil in different mass ratios, and perform ball milling. At the same time, 0.03% mass ratio of dispersant (montanic acid ester) is added, and 0.02% mass ratio of emulsifier (sodium stearate and saponin emulsification agent), the ball mil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film diameter | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Film diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com