Graphite pulverizing and demagnetizing device for battery material

A battery material and crushing device technology, applied in the field of mechanical equipment, can solve the problems of unreachable, time-consuming, and high risk, and achieve the effects of simple design structure, good development prospects, and good work performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

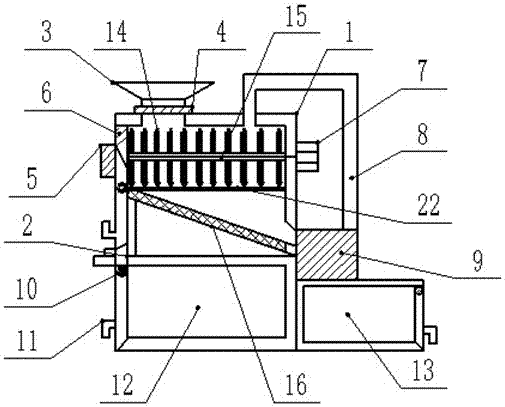

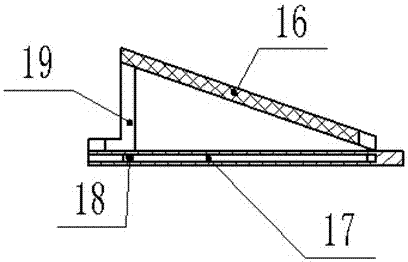

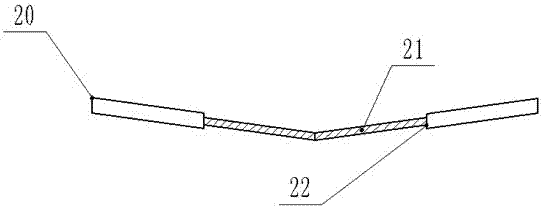

[0017] see Figure 1-3 , a graphite crushing and demagnetizing device for battery materials, comprising a crushing device 1 and a demagnetizing device 2; , transparent block 6, base plate 22, thick plate 20, thin plate 21, feeder 9 and feed pipe 8; the feed inlet 3 is fixedly connected to the upper left position of the crushing device 1, and the raw material enters the pulverization through the feed inlet 3 In the device 1; the fastener 4 is fixed at the position directly below the feed port 3, and the fastener 4 controls the opening and closing of the feed port 3; the motor 7 is fixed at the right side of the crushing device 1 Described rotating shaft 15 is vertically affixed to the left center position of motor 7, and motor 7 drives rotating shaft 15 to rotate; Described blade 14 several evenly affixed on the rotating shaft 15, and rotating shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com