A kind of compound polysaccharide hemostatic composition and its preparation method and application

A technology of complex polysaccharides and compositions, which is applied in the fields of application, drug delivery, and pharmaceutical formulations, and can solve problems such as unfavorable product molding and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

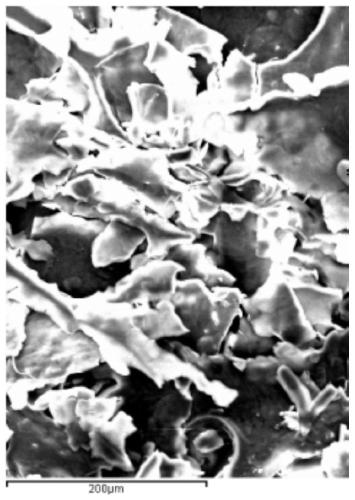

Image

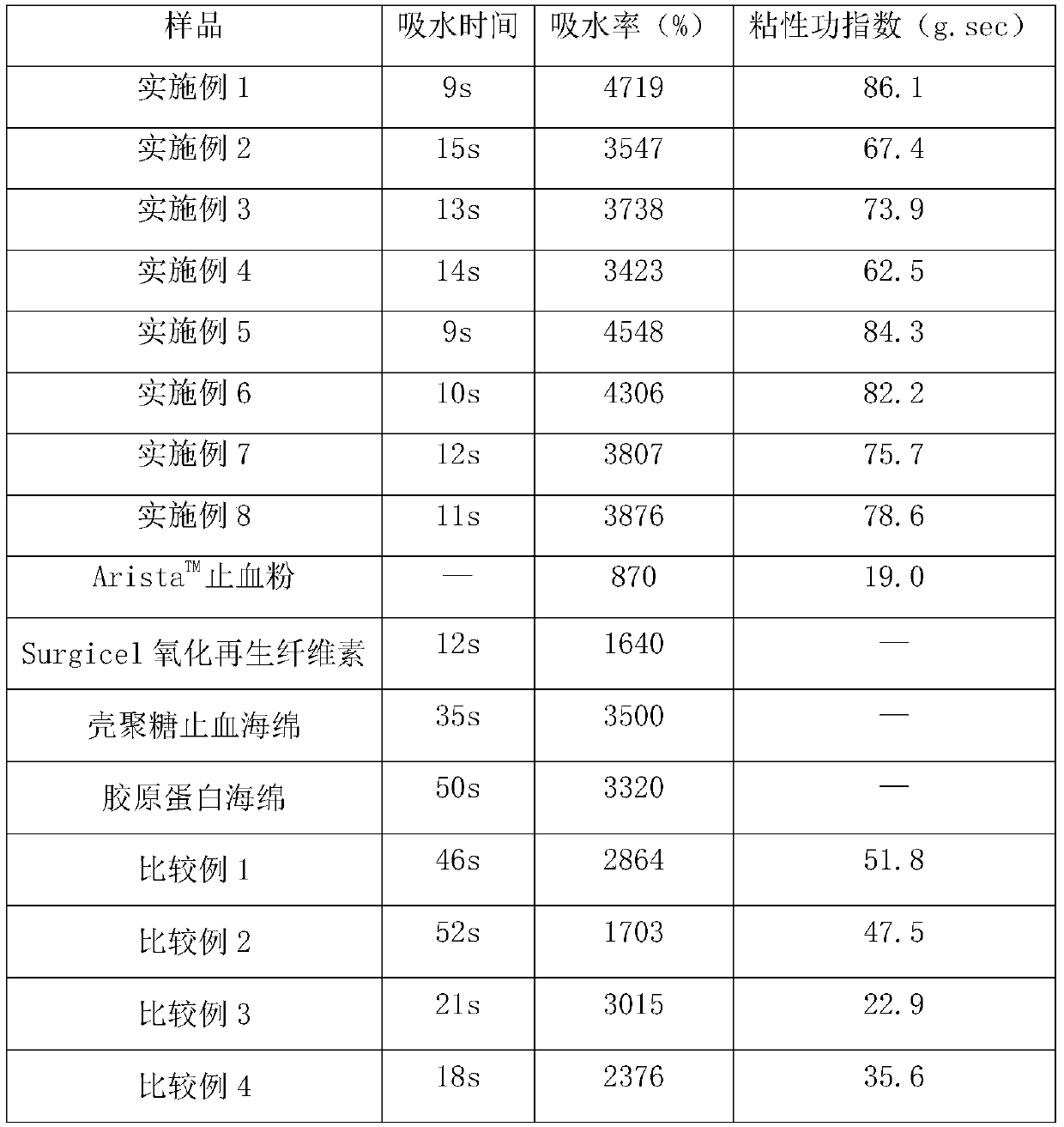

Examples

preparation example Construction

[0045] (1) Preparation of micro-crosslinked modified starch: Weigh two or more raw materials of modified starch, add them into distilled water respectively, and keep stirring to make modified starch liquid; the mass ratio of modified starch raw material to distilled water is 1:( 10-100). Use sodium hydroxide solution to adjust the pH value of each modified starch solution to 8-11, adjust the temperature of the modified starch solution to 30°C-80°C, add cross-linking agents to each modified starch solution, stir vigorously, and micro-crosslinking occurs Reaction, the reaction time is 0.5-48 hours, the quality of the crosslinking agent is 0.1wt%-8wt% of the quality of each modified starch raw material; then it is washed with water, dehydrated with absolute ethanol, and dried at 30°C-60°C for 2-48h, Several kinds of micro-crosslinked modified starches were obtained;

[0046] Modified starch raw materials can be etherified starch, specifically carboxymethyl starch, hydroxyethyl s...

Embodiment 1

[0055] (1) Weigh 3g of carboxymethyl starch and add it to 100ml of distilled water, stir continuously to make carboxymethyl starch liquid, pour it into the reaction kettle, the temperature of the water bath is 60°C, adjust the pH value between 8-11, add 0.2 g of epichlorohydrin, vigorously stirred for 3 hours; then washed with water, dehydrated with absolute ethanol, and air-dried at 50°C for 4 hours to obtain slightly cross-linked carboxymethyl starch.

[0056] Weigh 3g of hydroxyethyl starch and add it to 100ml of distilled water, stir continuously to make hydroxyethyl starch liquid, pour it into the reaction kettle, the temperature of the water bath is 60°C, adjust the pH value between 8-11, add epoxy chlorine Propane 0.2g, vigorously stirred for 3 hours; then washed with water, dehydrated with absolute ethanol, and air-dried at 50°C for 4 hours to obtain slightly cross-linked hydroxyethyl starch.

[0057] (2) Take by weighing 0.5g slightly cross-linked carboxymethyl starch...

Embodiment 2

[0064] Step (1) is with embodiment 1.

[0065] (2) Weigh 0.99 g of slightly cross-linked carboxymethyl starch and 0.01 g of slightly cross-linked hydroxyethyl starch, add them into 90 ml of distilled water, and stir continuously to prepare starch liquid.

[0066] (3) Weigh 0.05 g of hydroxyethyl cellulose, add it to 5 ml of distilled water, and keep stirring to make a hydroxyethyl cellulose solution;

[0067] (4) Mix the liquids obtained in the above steps (2) and (3) under stirring, then add 0.15 g of propylene glycol, and stir vigorously for 1 hour.

[0068] (5) Pour the material liquid obtained in step (4) into a freeze-drying mold, pre-freeze in a freezer at -25°C for 4 hours, and then vacuum freeze-dry at -35°C and a vacuum degree of less than 20Pa After 40 hours, a spongy compound polysaccharide hemostatic composition was obtained.

[0069] Get the above-mentioned block composition of 10mm * 50mm specification, measure its tensile strength by the method of embodiment 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com