High-degradation rate diversion layer material and preparing method thereof

A technology of degradation rate and diversion layer, which is applied in medical science, absorbent pads, bandages, etc., can solve the problems of poor diversion performance, difficult to degrade, and difficult processing of water-locking diversion layer, so as to increase air permeability, good The effect of moisture permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

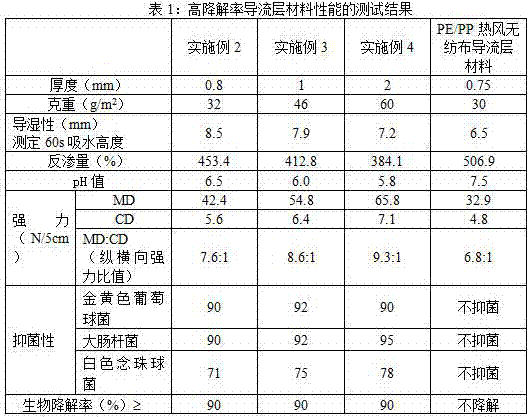

Examples

Embodiment 1

[0029] (1) Blend polylactic acid fibers with a fineness of 1.5D and 3-6D respectively according to the ratio of 15-30:85-70. After opening, mixing, carding and air stripping, a grammage of 12- 20g / m 2 The upper fiber web of the airflow stripping process adopts suction type airflow stripping, and the main parameters of the airflow stripping process are: the rotating speed of the main cylinder is 2200-2500r / min, and the speed of the horizontal blower is 950-1250r / min, the air volume in the pipeline is 210-220m 3 / min, the suction fan coefficient is 75-85%, and the negative pressure under the net curtain is 800-920Pa.

[0030] (2) Prepare the antistatic agent solution according to the mass ratio of antistatic agent to water of 4-8:92-96, and use the antistatic agent solution to antistatic the polylactic acid fiber with a fineness of 1.1-1.5D treatment, the spraying amount of the antistatic agent solution is 8-16% of the weight of the polylactic acid fiber with a fineness of 1....

Embodiment 2

[0039] 1. Selection of raw materials

[0040] Hydrophilic polylactic acid fibers with fineness × length of 1.5D × 38mm and 3D × 51mm were selected, and the oil content on the surface of the fibers was 3%, and water-repellent polylactic acid fibers with a fineness of 1.1D × 38mm were selected, and the surface of the fibers contained oil The rate is 5%. The above-mentioned polylactic acid fibers are two-component polylactic acid fibers composed of low-melting point parts and high-melting point parts. The melting point of the high melting point part of the one-component polylactic acid fiber is 155-160 °C, and the arrangement structure composed of the low melting point part and the high melting point part of the two-component polylactic acid fiber is concentric.

[0041] 2. Preparation method

[0042]1) Blend 1.5D×38mm and 3D×51mm polylactic acid fibers at a ratio of 15:85. After opening, mixing, carding and air stripping, the upper fiber web is formed. When using suction air st...

Embodiment 3

[0048] 1. Selection of raw materials

[0049] Hydrophilic polylactic acid fibers with fineness × length of 1.5D × 38mm and 5D × 51mm were selected, and the oil content on the surface of the fibers was 2%. The rate is 3%. The above-mentioned polylactic acid fibers are two-component polylactic acid fibers composed of low-melting point parts and high-melting point parts. The melting point of the high melting point part in the one-component polylactic acid fiber is 160-170 °C, and the arrangement structure composed of the low melting point part and the high melting point part of the two-component polylactic acid fiber is eccentric.

[0050] 2. Preparation method

[0051] 1) 1.5D×38mm and 5D×51mm polylactic acid fibers are blended according to the ratio of 20:80. After opening, mixing, carding and air stripping, the upper fiber web is formed. When using suction air stripping The rotation speed of the main cylinder is 2350r / min, the speed of the horizontal blower is 1050r / min, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Gram weight | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com