A preparing method of a polyethylene fine-denier moisture-conducting fiber

A polyethylene and wet fiber technology, applied in the direction of single-component polyolefin rayon, dry spinning method, stretch spinning method, etc. Water-based, poor wearing comfort and other issues, to achieve the effect of improving the moisture-wicking effect, good textile processing performance, and improved wearing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

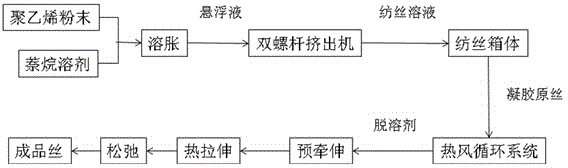

[0019] Embodiment 1: a kind of production technology of polyethylene superfine denier fiber:

[0020] Prepare the swelling suspension of polyethylene powder in decalin. The mass ratio of ultra-high molecular weight polyethylene and decalin for fibers with a molecular weight of 4 million to 8 million is 1:10. Extruded and sheared by a twin-screw extruder , fully dissolved to obtain polyethylene solution, the temperature of each zone of the screw is 90-180°C; the polyethylene solution is spun through the spinneret, and the tow is removed from the decalin by the hot air circulation system, which is a closed heating chamber with nitrogen circulation. Wind temperature 145°C, air volume 135 m 3 / h; After pre-stretching, the stretching ratio is 3.0, and thermal stretching is performed in one or more steps, the temperature of the multi-stage thermal stretching hot box is 140-150°C, and the total thermal stretching ratio is 5.0; One or more relaxation steps, the relaxation temperature...

Embodiment 2

[0023] Embodiment 2: a kind of production technology of polyethylene superfine denier fiber:

[0024] Prepare the swelling suspension of polyethylene powder in decalin. The mass ratio of ultra-high molecular weight polyethylene and decalin for fibers with a molecular weight of 4 million to 8 million is 1:20. Extruded and sheared by a twin-screw extruder The polyethylene material is fully unwound with polyethylene solution, and the temperature of each zone of the screw is 90-180°C; the polyethylene solution is spun on the spinneret, and the tow is removed from the decalin by the hot air circulation system, which is a closed heating chamber with nitrogen circulation. Room, air temperature 70°C, air volume 160 m 3 / h; after pre-stretching, the stretching ratio is 1.0, and hot-stretched in one or more steps, the temperature of the multi-stage hot-stretching hot box is 120-140°C, and the total stretching ratio is 8.0; One or more relaxation steps, the relaxation temperature is 120...

Embodiment 3

[0027] Embodiment 3: a kind of production technology of polyethylene superfine denier fiber:

[0028] Prepare the swelling suspension of polyethylene powder in decalin. The mass ratio of ultra-high molecular weight polyethylene and decalin for fibers with a molecular weight of 4 million to 8 million is 1:10. Extruded and sheared by a twin-screw extruder The polyethylene material is fully unwound with polyethylene solution, and the temperature of each zone of the screw is 90-180°C; the polyethylene solution is spun through the spinneret, and the tow is removed from the decalin by the hot air circulation system, which is closed heating with nitrogen circulation Chamber, air temperature 110°C, air volume 90 m 3 / h; After pre-stretching, the stretching ratio is 4.0, and thermal stretching is carried out in one or more steps, the temperature of the multi-stage thermal stretching hot box is 90-120°C, and the total thermal stretching ratio is 10.0; One or more relaxation steps, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com