Fresh corn processing system

A technology of fresh corn kernels and processing system, which is applied in the direction of preservation of seeds by freezing/cooling, degermination of grains, depodization of grains, etc., which can solve the problems of crushing, uneven hardness inside and outside the grains, and difficult separation of grain skins.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1 A kind of fresh corn grain processing system

[0030] A fresh corn grain processing system, which includes: a washing machine, a cooking device, a draining device, a freezing device, a frozen block crushing device, and a peeling machine.

Embodiment 2

[0031] Embodiment 2 cooking device

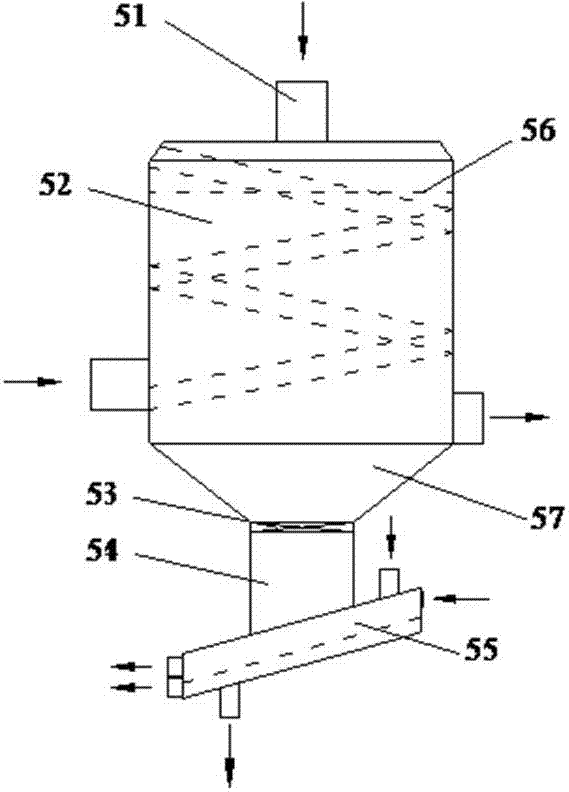

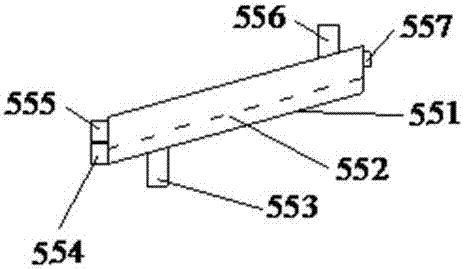

[0032] like Figure 1-2 As shown, the cooking device includes: a cooking tank body with a steam pipeline installed inside and a cooling pipe 55 obliquely arranged below the cooking tank body;

[0033] The cooking tank body includes: a cooking shell 52, a raw material inlet 51 arranged above the cooking shell 52, a spiral pipe 56 connected to the inner surface of the cooking shell 52, a The steam inlet pipe, the return pipe arranged on the side opposite to the steam inlet pipe, the second cone 57 located below the cooking shell, and the cylinder 54 connected to the bottom of the second cone 57 .

[0034] The raw material inlet 51 of the cooking device is located at the center above the cooking shell 52 of the cooking device. A spiral pipe 56 is arranged in the cooking shell 52, and a steam inlet pipe and a nozzle of a return pipe are arranged on the cooking shell. The spiral pipe 56 is attached to the inner wall of the cooking shell, and h...

Embodiment 3

[0039] Embodiment 3 draining device

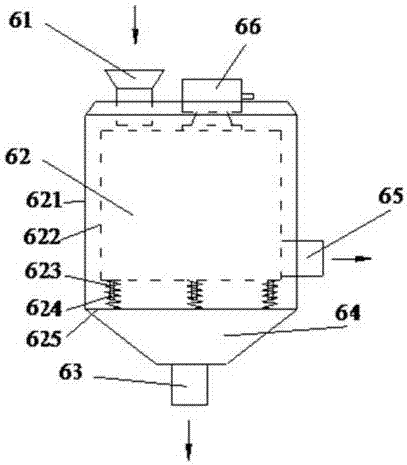

[0040] The draining device comprises: a draining tank housing 62, an inlet pipe 61 positioned above the draining tank housing, a draining cone housing 64 positioned below the draining tank housing 62, an outlet tube positioned below the draining cone housing 64. Shuikou pipe 63, the fresh corn grain outlet pipe that is positioned at described draining cone housing below;

[0041] The draining device also includes: a vibration motor 66; the vibration motor 66 is installed above the drain tank body 62;

[0042] The drain tank housing 62 is also provided with: a plurality of vertical support rods 623, a vibrating screen 622 arranged above the vertical support rods 623 and a spring 624 arranged on the vertical support rods;

[0043] The vibrating motor 66 is used to drive the vibrating screen 622 to vibrate; the vertical support rod 623 is used to support the vibrating screen 622 ; the top of the spring 624 is connected to the bottom surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com