Spinning method of large-difference AB slubby yarn through siro-compact spinning

A technology of compact siro yarn and slub yarn, which is applied in the field of spinning, can solve the problems of reduced product quality, high yarn hairiness, and low strength, and achieve the effects of improving product quality, reducing yarn hairiness, and increasing yarn strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037]Embodiment 1, the spinning method of combed cotton and polyester blended siro compact spinning with large difference AB slub yarn.

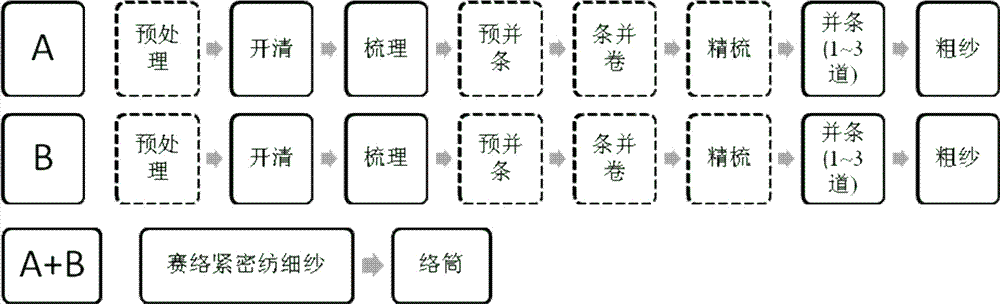

[0038] (1) The process flow is:

[0039] Combed cotton: blowing and carding → pre-drawing → sliver and coil → combing → drawing → roving;

[0040] Polyester: fiber pretreatment→fiber pretreatment→cleaning→carding→→drawing (2 passes)→roving;

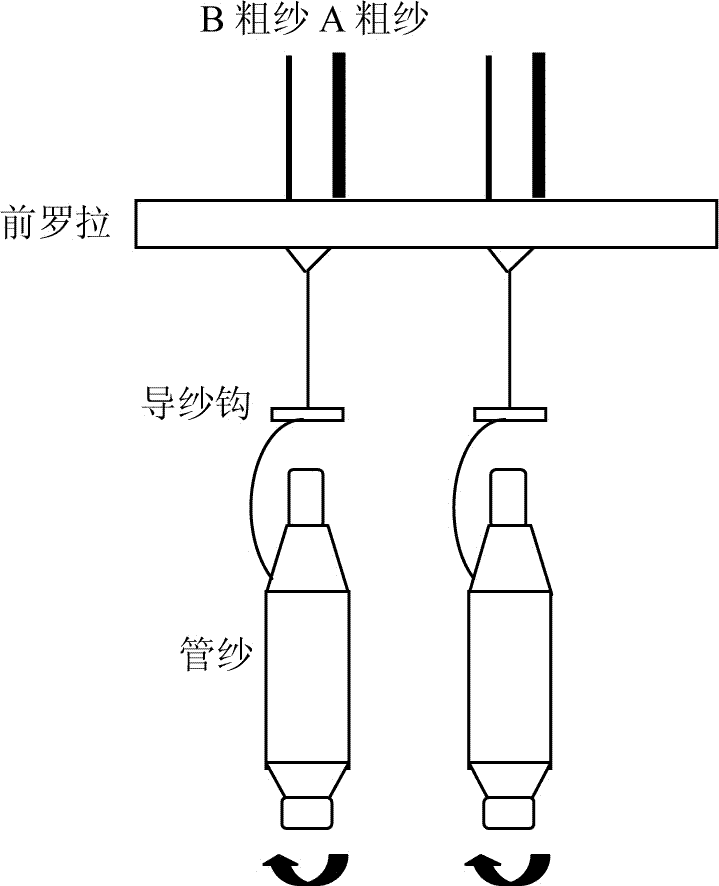

[0041] Combed cotton roving + polyester roving: Siro compact spinning → automatic winding.

[0042] (2) Process technology of each process:

[0043] Pretreatment of raw materials: weigh the polyester fibers and spread them manually, and prepare a health care solution according to the dry weight of the polyester fibers. The composition of the health care solution is a mixed solution of 0.3% antistatic agent by the dry weight of the fibers + 3% clear water by the dry weight of the fibers. Spray the nourishing solution evenly on the polyester fiber with a sprayer, stir and mix, and then seal it for 24 ...

Embodiment 2

[0053] Example 2: The spinning method of Tencel and polyester blended Siro compact spinning with big difference AB slub yarn.

[0054] (1) The process flow is:

[0055] Tencel: cleaning → carding → → drawing (2 passes) → roving;

[0056] Polyester: fiber pretreatment→fiber pretreatment→cleaning→carding→→drawing (2 passes)→roving;

[0057] Tencel roving + polyester roving: Siro compact spinning → automatic winding.

[0058] (2) Process technology of each process:

[0059] Except roving, all the other pre-spun production processes of polyester fiber are the same as embodiment one;

[0060] Tencel production process is as follows:

[0061] Blowing and carding: Blowing and carding unit is adopted, and the equipment configuration is FA002A disc catching machine → FA028C multi-compartment blending machine → FA1124-120 single-roller cleaning machine → FA051A cotton condenser + TF26A cotton condenser overhead device + ZF9104-425 (5.5) Cotton conveying fan → FA221E carding machine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com