A kind of anticorrosion technology of anticorrosion tank

A technology of technology and branch, which is applied in the anticorrosion process field of anticorrosion tanks, can solve the problems of large investment in anticorrosion, large floor space, and increased cost, and achieve the effect of improving quality, small floor space, and increasing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The anticorrosion process of a kind of anticorrosion tank described in this embodiment comprises the following steps:

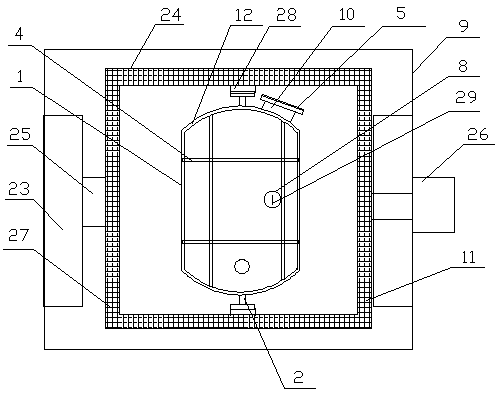

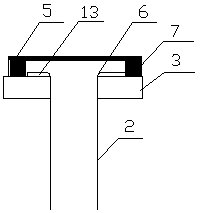

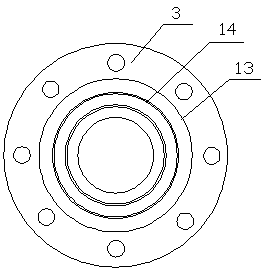

[0033] (1) Derust and sandblast the inside of the anticorrosion tank 1, each branch 2, and the surface of the flange 3. After sandblasting, the surface cleanliness reaches Sa3 level and the roughness is 75 μm. The flange 3 is a plate-type flat-welded flange. The surface of the flange 3 is provided with a protruding surface 13, and a circular groove 14 is provided on the protruding surface;

[0034] (2) The corners of each branch of the anti-corrosion tank 1 are polished into an arc 6, and there are two sets of cross-shaped grooves 4 inside the tank body, and the grooves 4 are semicircular grooves;

[0035] (3) Prepare anti-corrosion raw materials, the anti-corrosion raw materials are mixed with ultra-fine FEP powder and talc powder, wherein the mass ratio of FEP is 82%, and the ultra-fine FEP powder is a powder with a particle size of 8 μm;

[0036] (...

Embodiment 2

[0044] The anticorrosion process of a kind of anticorrosion tank described in this embodiment comprises the following steps:

[0045] (1) Derust and sandblast the inside of the anticorrosion tank 1, each branch 2, and the surface of the flange 3. After sandblasting, the surface cleanliness reaches Sa3 level, and the roughness is 80 μm. The flange 3 is a plate type flat welding flange. The flange surface is provided with a protruding surface 13, and a circular groove 14 is provided on the protruding surface;

[0046] (2) The corners of each branch of the anticorrosion tank 1 are polished into an arc 6, and a set of cross-shaped grooves 4 are arranged inside the tank body, and the grooves 4 are semicircular grooves;

[0047] (3) Prepare anti-corrosion raw materials, the anti-corrosion raw materials are mixed with ultrafine FEP powder and talc powder, wherein the mass ratio of FEP is 86%, and the ultrafine FEP powder is a powder with a particle size of 5 μm;

[0048] (4) One branc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com