Preparation and application methods for non-noble metal catalyst used for liquid-phase reaction system used in acetylene hydrogenation

A liquid-phase reaction, acetylene hydrogenation technology, applied in metal/metal oxide/metal hydroxide catalysts, catalysts, hydrogenation to hydrocarbons, etc. The problem of high cost, to achieve the effect of excellent catalytic ability, easy control, simple and fast operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

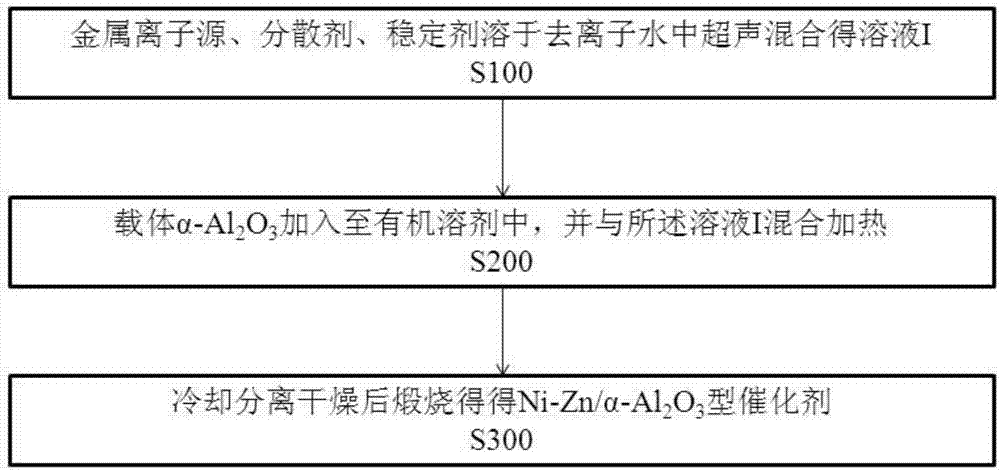

[0030] A method for preparing a non-noble metal catalyst for acetylene hydrogenation liquid phase reaction system, comprising the steps of:

[0031] In the step (1) shown in box S100, weigh 6g of nickel nitrate and 20g of zinc nitrate and dissolve them in 30g of deionized water, add 1g of hexamethylenetetramine and 1g of PVP at the same time and ultrasonicate for 10 minutes at 60°C. Set as 360W, recorded as solution I;

[0032] In step (2) shown in frame S200, take the α-Al of 100g 2 o 3 Add it to 60g of NMP, mix it with the above solution I, and transfer it to a static kettle, place it in an ultrasonic container, use an oil bath, set the temperature at 120°C, and control the ultrasonic power at 360W, and control the time for 2 hours;

[0033] In the step (3) shown in block S300, keep the ultrasound turned on and naturally cool to room temperature, centrifuge the mixed solution, take the solid matter, wash it with absolute ethanol for 2 to 3 times, filter it with suction, dr...

Embodiment 2

[0038] A method for preparing a non-noble metal catalyst for acetylene hydrogenation liquid phase reaction system, comprising the steps of:

[0039] Step (1) shown in block S100 is the same as embodiment 1;

[0040] In the step (2) shown in block S200, the temperature of the oil bath is set to 140°C, the power is increased to 420W, and the time is controlled for 3 hours, and the rest are the same as in Example 1;

[0041] Step (3) shown in block S300 and the application method of the non-noble metal catalyst used in the acetylene hydrogenation liquid phase reaction system are the same as in Example 1.

Embodiment 3

[0043] A method for preparing a non-noble metal catalyst for acetylene hydrogenation liquid phase reaction system, comprising the steps of:

[0044] In step (1) shown in box S100, add 4g hexamethylenetetramine and 2g PVP, all the other are the same as embodiment 1;

[0045] In the step (2) shown in block S200, the power is increased to 960W, the oil bath is 120°C, and the time is controlled for 4 hours, and the rest are the same as in Example 1;

[0046] Step (3) shown in block S300 is the same as that in Embodiment 1.

[0047] A method for applying a non-precious metal catalyst in a liquid-phase reaction system for hydrogenation of acetylene, comprising the following steps:

[0048] Step 1) is the same as embodiment 1;

[0049] Step 2) Put the obtained catalyst and nitrogen-methylpyrrolidone (NMP) into a reactor to form a solution, hydrogen and acetylene form a raw material gas with a molar ratio of 5:1, and react continuously at 145°C, and the rest of the conditions are th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com