Fiber green tea beverage and preparation method thereof

A green tea beverage and fiber technology, applied in the field of fiber green tea beverage and its preparation, can solve the problems of precipitation and deposition, poor stability of fiber green tea, affecting the quality of fiber green tea, etc., and achieves the effects of good stability and improved stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

[0053] Components and content weight thereof adopted in table 1 embodiment 1~5

[0054] Example 1 Example 2 Example 3 Example 4 Comparative example 1 Comparative example 2 Roasted green tea (g) 2 3 4 3 3 3 Roasted Green Tea (g) 2- 4 2.5 3 3 3 Steamed green tea (g) 3 2 2.5 2.5 2.5 2.5 Brown rice (g) 0.2 0.8 1 0.5 0.5 0.5 Oolong tea (g) 2 3 4 2.5 2.5 2.5 White sugar (g) 20 15 10 16 16 16 Resistant dextrin (g) 19 — 30 — — — Polydextrose (g) — 23 — 15 17 17 honey (g) 0.1 0.5 0.3 - 0.2 0.2 Antioxidant (g) 0.1 0.2 0.3 0.1 0.1 0.1 Sodium citrate (g) 0.3 0.4 0.5 0.3 0.1 0.2 Stabilizer (g) 0.2 0.3 0.2 0.1 0.2 0.2 Sodium bicarbonate (g) 0.1 0.27 0.4 0.17 0.17 0.17 Flavor (g) 0.6 0.8 0.7 1.0 1.0 1.0 water margin margin margin margin margin margin

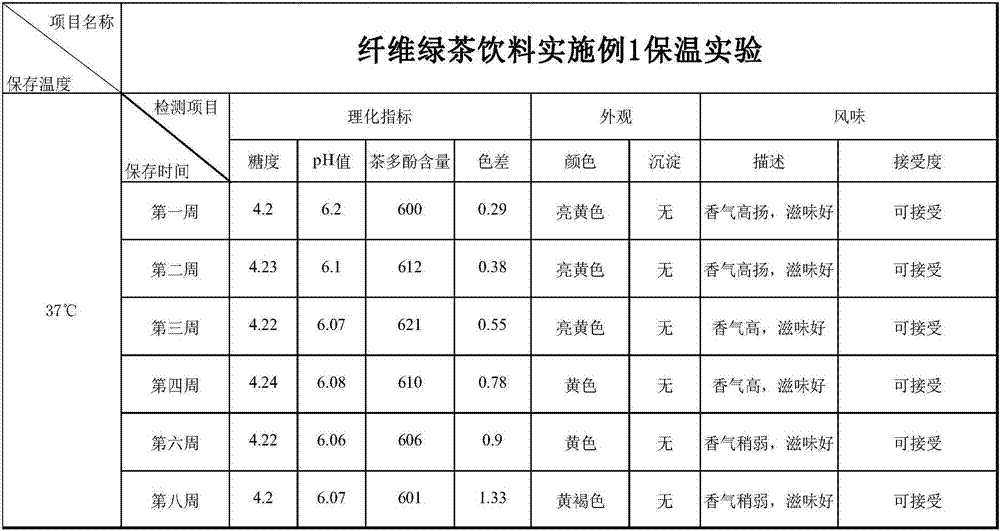

Embodiment 1

[0056] Weigh tea leaves and brown rice according to Table 1, add them to water for extraction, the ratio of tea to water is 1:20, the extraction time is 8 minutes, and the extraction temperature is 60°C; according to Table 1, pre-dissolve the resistant dextrin in warm water and add it to the extract , and then add white sugar, honey, vitamin C, sodium citrate, sodium hexametaphosphate, sodium bicarbonate and food flavor to the extract, make up RO water to prepare a fiber green tea blend, and the fiber green tea blend is sterilized by UHT, The sterilization temperature is 138°C, and the sterilization time is 18 seconds, and the finished fiber green tea is obtained, the tea polyphenols are 600ppm, and the pH is 6.1.

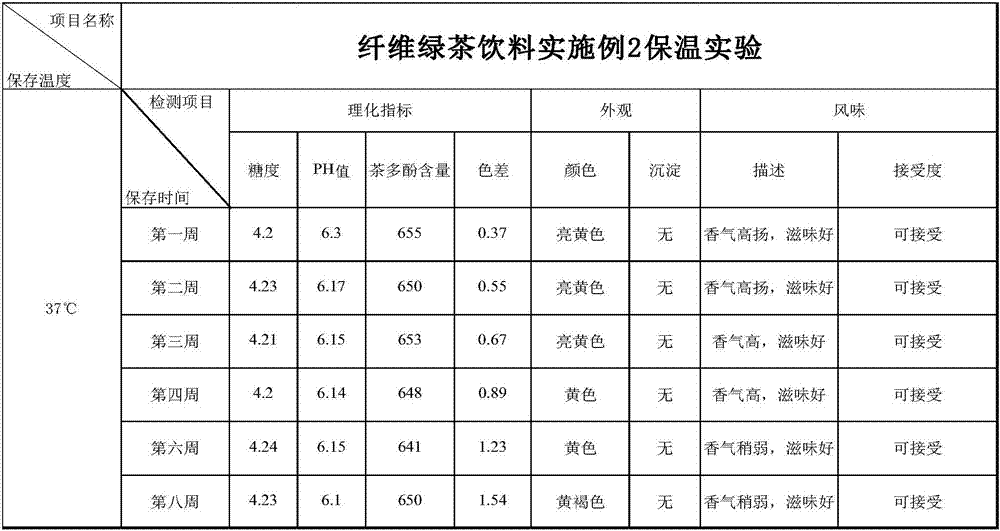

Embodiment 2

[0058] Weigh tea leaves and brown rice according to Table 1, add them to water for extraction, the ratio of tea to water is 1:40, the extraction time is 9 minutes, and the extraction temperature is 70°C; according to Table 1, pre-dissolve polydextrose in warm water and add it to the extract. Then white granulated sugar, honey, vitamin C (0.1g), D‐sodium erythorbate (0.1g), sodium citrate, disodium dihydrogen pyrophosphate, sodium bicarbonate and food flavors are added to the extract to supplement the RO water The fiber green tea blend was prepared, and the fiber green tea blend was sterilized by UHT at a temperature of 140° C. and a sterilization time of 17 seconds to obtain a finished fiber green tea with tea polyphenols of 650 ppm and pH of 6.1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com