Small-sized welding packaging high power simulation optical module

A technology for welding packaging and optical modules, which is applied in the direction of light guides, optics, and optical components, can solve problems such as increased difficulty of development projects, extended development cycles, and device compatibility that affect the operation reliability of final products, so as to save raw materials and space. The effect of stable linear range and small form factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

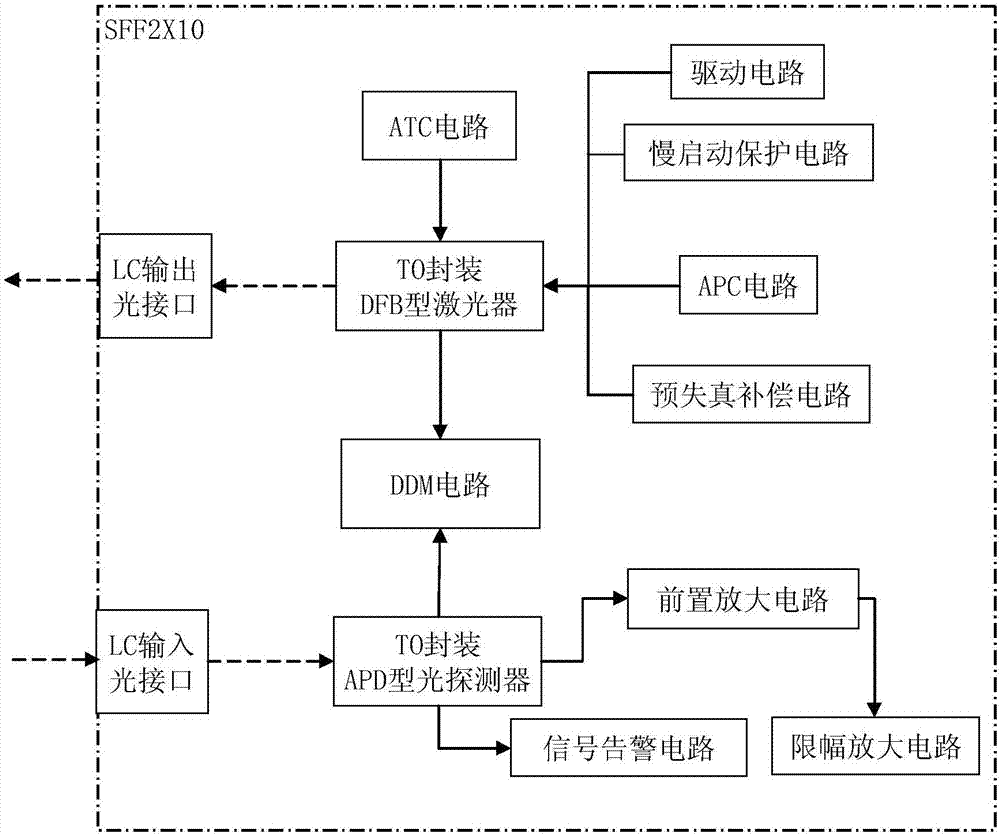

[0022] The implementation of the high-power analog optical module in this miniaturized solderable package is as an example figure 1As shown, the dotted arrows in the figure indicate the optical signal connection, and the solid line arrows indicate the electrical signal connection. The emitting optoelectronic device of the optical module in this example is a DFB analog laser. The core of the analog laser light source stripped of the redundant external circuit is placed in a TO package and coaxially packaged. The receiving optoelectronic device is an APD type photodetector, which is placed in another TO package. Inner coaxial package. The analog laser and photodetector are respectively connected to the LC-type output and input optical interfaces. The drive circuit and the slow start protection circuit are connected to the DFB laser, and the DFB laser is also connected to the automatic power control APC circuit and the pre-distortion compensation circuit. The DFB laser is equipp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com