Energy-saving material for setting up building construction wall and preparation method thereof

An energy-saving material and building construction technology, which is applied in the field of building materials to achieve the effects of good wear resistance, improved sound insulation performance, and dry shrinkage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

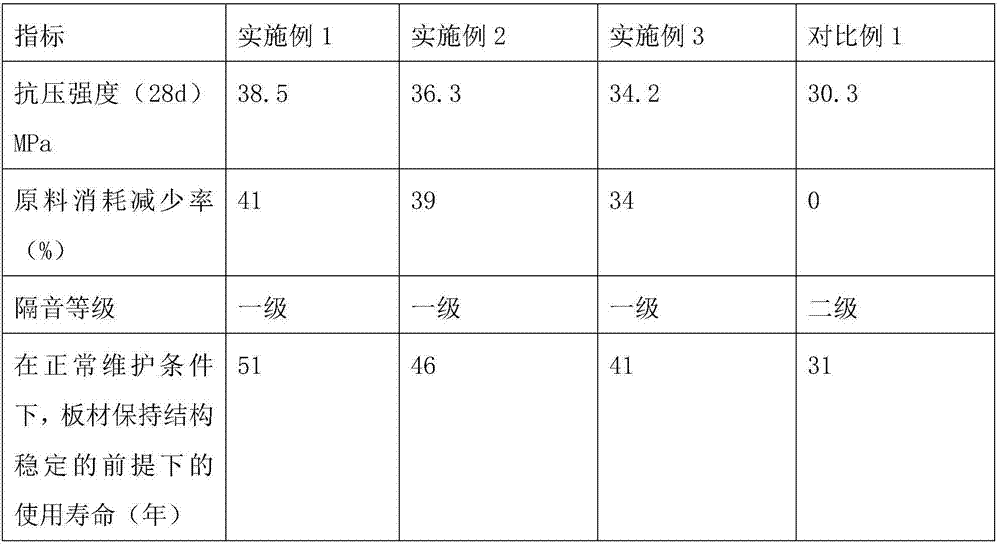

Examples

Embodiment 1

[0036] An energy-saving material for building construction walls, including the following raw materials in parts by weight: 18 parts of fine sand, 24 parts of gravel, 20 parts of cement, 25 parts of waste foamed cement, 17.5 parts of waste gypsum board, 12.5 parts of waste cork board 18 parts of iron alloy slag, 4 parts of fly ash, 22.5 parts of slag wool, 37.5 parts of polyester fiber sound-absorbing board, 1.1 parts of water reducing agent and 4 parts of water.

[0037] Waste foamed cement, waste gypsum board, waste cork board, ferroalloy slag, fly ash and slag wool are added to the raw materials. These construction waste and industrial waste have solved the problem of large consumption of building wall materials but cannot be reused. , to achieve the purpose of energy saving and environmental protection.

[0038] Waste foamed cement contains a large number of independent and evenly distributed closed pores, which is characterized by light weight and sound insulation.

[00...

Embodiment 2

[0055] An energy-saving material for building construction walls, comprising the following raw materials in parts by weight: 12-24 parts of fine sand, 22-26 parts of gravel, 15-25 parts of cement, 21-29 parts of waste foamed cement, and waste gypsum Board 15-20 parts, waste cork board 10-15 parts, ferroalloy slag 12-24 parts, fly ash 3-5 parts, slag cotton 20-25 parts, polyester fiber sound-absorbing board 35-40 parts, water reducer 0.8 -1.4 parts and 3-5 parts of water.

[0056] Waste foamed cement, waste gypsum board, waste cork board, ferroalloy slag, fly ash and slag wool are added to the raw materials. These construction waste and industrial waste have solved the problem of large consumption of building wall materials but cannot be reused. , to achieve the purpose of energy saving and environmental protection.

[0057] Waste foamed cement contains a large number of independent and evenly distributed closed pores, which is characterized by light weight and sound insulatio...

Embodiment 3

[0073] An energy-saving material for building construction walls, comprising the following raw materials in parts by weight: 12-24 parts of fine sand, 22-26 parts of gravel, 15-25 parts of cement, 21-29 parts of waste foamed cement, and waste gypsum Board 15-20 parts, waste cork board 10-15 parts, ferroalloy slag 12-24 parts, fly ash 3-5 parts, slag cotton 20-25 parts, polyester fiber sound-absorbing board 35-40 parts, water reducer 0.8 -1.4 parts and 3-5 parts of water.

[0074] Waste foamed cement, waste gypsum board, waste cork board, ferroalloy slag, fly ash and slag wool are added to the raw materials. These construction waste and industrial waste have solved the problem of large consumption of building wall materials but cannot be reused. , to achieve the purpose of energy saving and environmental protection.

[0075] Waste foamed cement contains a large number of independent and evenly distributed closed pores, which is characterized by light weight and sound insulatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com