Automatic tobacco material drying intensity regulating system applicable to microwave and fixed bed hot air combined drying process as well as method using regulating system

A technology of combined drying and microwave fixation, which is applied in the direction of temperature control, tobacco, and tobacco preparation using electric means, can solve the problem of difficult to achieve consistent processing, and cannot ensure that tobacco processing enterprises can obtain cigarette products with stable quality on a large scale, and the control method Lack of universality and other issues to achieve the effect of ensuring quality, avoiding uncertainty, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below in conjunction with accompanying drawing of the present invention, the present invention and working method thereof are further described:

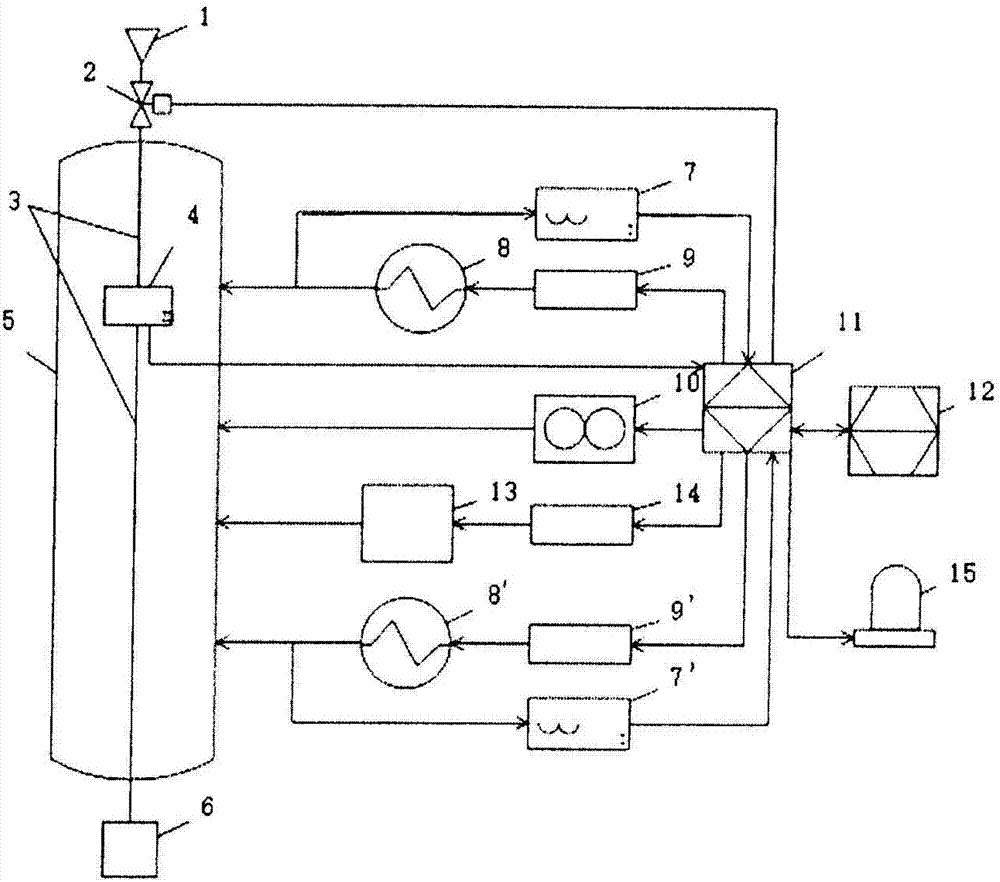

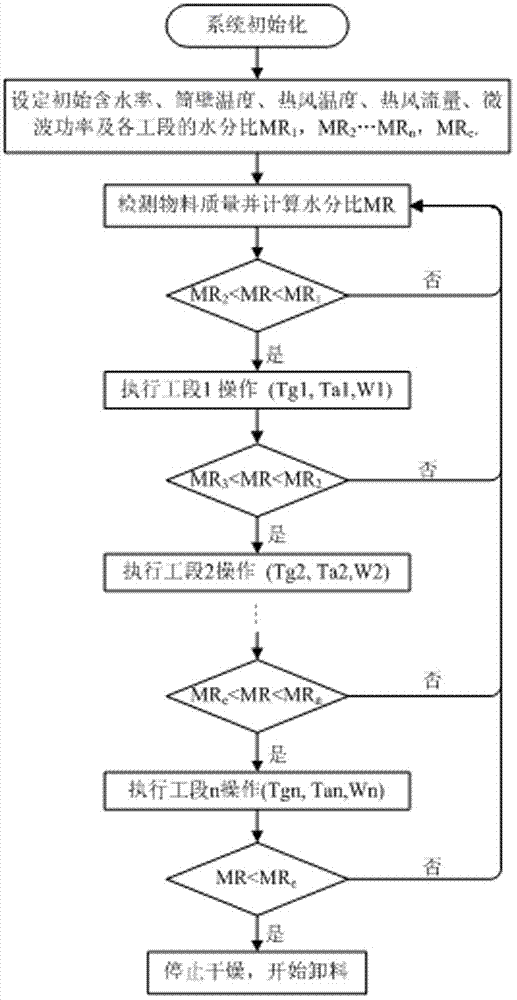

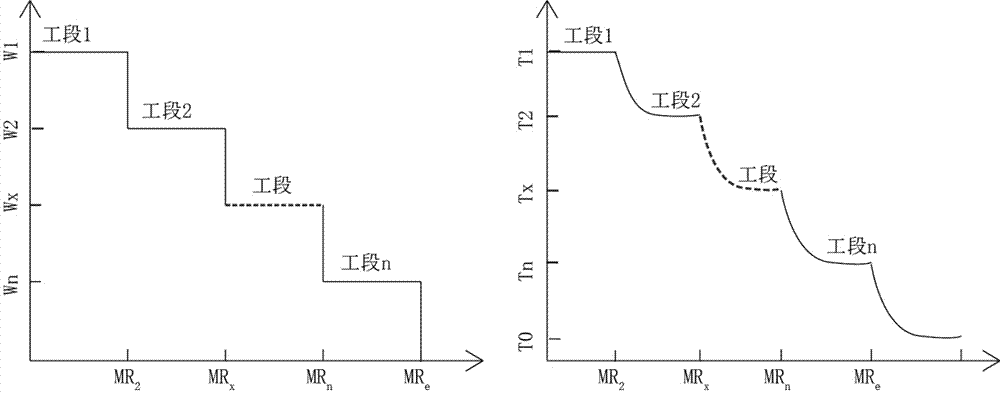

[0035] The purpose of the present invention is achieved through the following technical solutions: a tobacco material drying intensity automatic control system suitable for microwave fixed bed hot air combined drying process, including drying equipment main body 5 and associated with the drying equipment main body and can The automatic feeding and discharging control unit controlled by the working process and conditions, the hot air drying control unit, the cylinder wall temperature control unit, the detection control unit and the microwave power control unit, the automatic feeding and discharging unit consists of the feeding port 1, the discharge valve 2, the slide pipe 3. The hanging basket 4 and the feeder 6 are composed; the hot air drying control unit is composed of a hot air temperature sensor 7, a hot air electric heate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com