Modeling method of liquid sloshing in microgravity environment of spherical tank

A liquid sloshing and microgravity technology, applied in simulators, instruments, control/regulation systems, etc., can solve the problems of complex sloshing of propellant in the tank, difficulty in meeting engineering needs, and low solution efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

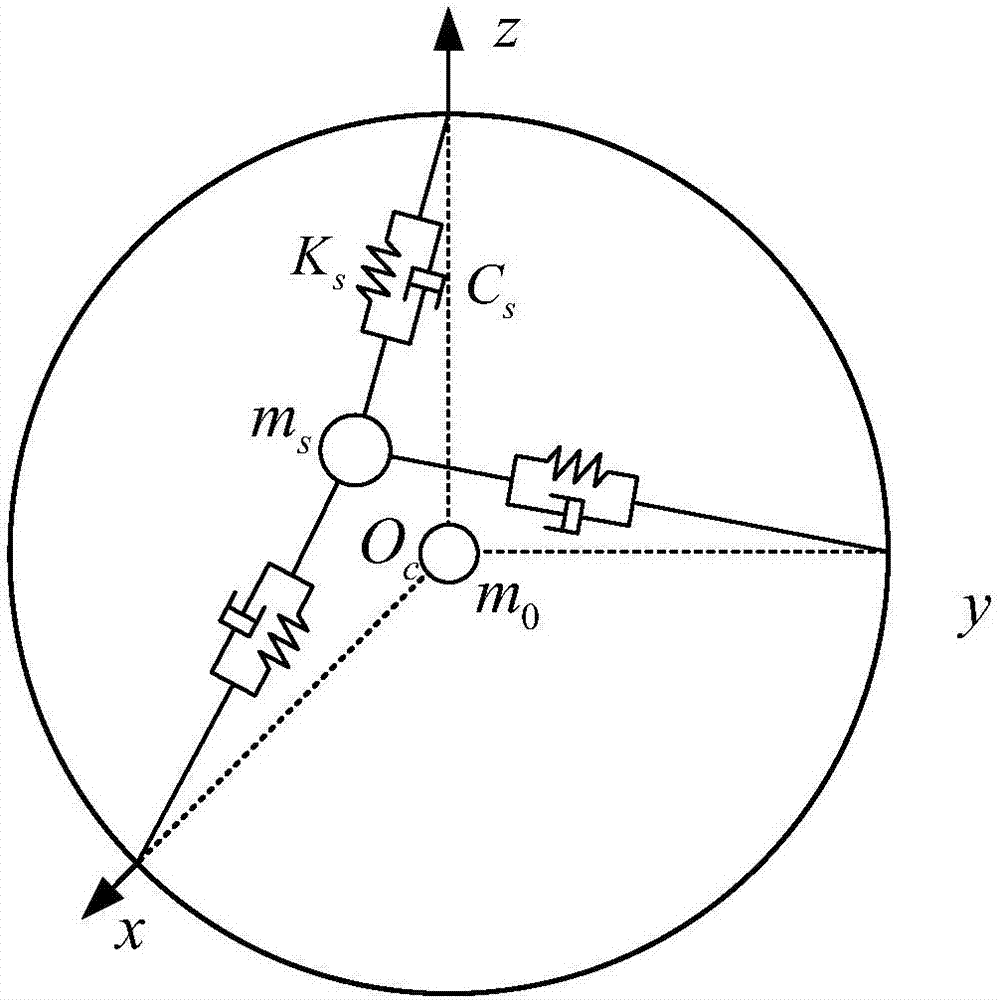

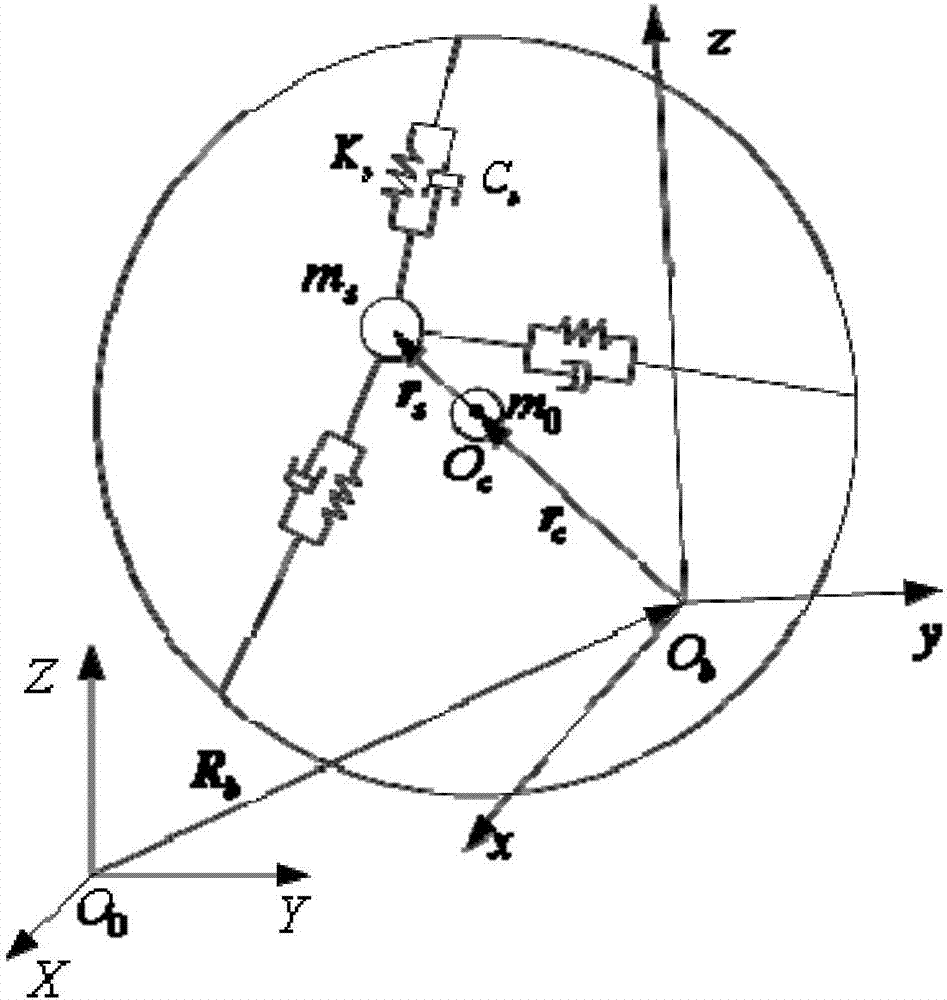

[0170] The radius of the spherical storage tank is R=0.547m, the liquid filling ratio is 25%, and the liquid is water at normal temperature. Obtain its equivalent spring-mass model by calculation, m s =102.8kg, m 0 =68.48kg, K s =0.14425N / m, C s = 0.2827 Ns / m.

[0171] The coordinates of the sphere center of the tank in the body coordinate system are (0.3,0.4,0.5)m, and the translation excitation along the x-axis direction and the rotation excitation around the x-axis direction are applied to the tank, and the motion laws are x=0.01sin (0.1πt)m and θ x =0.01sin(0.2πt)rad. The acceleration of gravity is along the negative direction of the z axis, and the magnitude is g=10 -5 m / s 2 . Obtain the force of the liquid on the tank as Figure 4 and as shown in 5. Figure 4 and Figure 5 The response of the same tank calculated under the same excitation conditions using the commercial software Flow-3d is also plotted. The comparison results show that the error is less than ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com