A polyurethane-based environmentally friendly flame-retardant anti-corrosion coating

An anti-corrosion coating, polyurethane technology, applied in the direction of polyurea/polyurethane coatings, anti-corrosion coatings, fire-retardant coatings, etc., can solve problems such as corrosion resistance and poor flame retardancy, and achieve good temperature resistance, good flame retardant performance, and enhanced anti-corrosion. Effects of Features

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

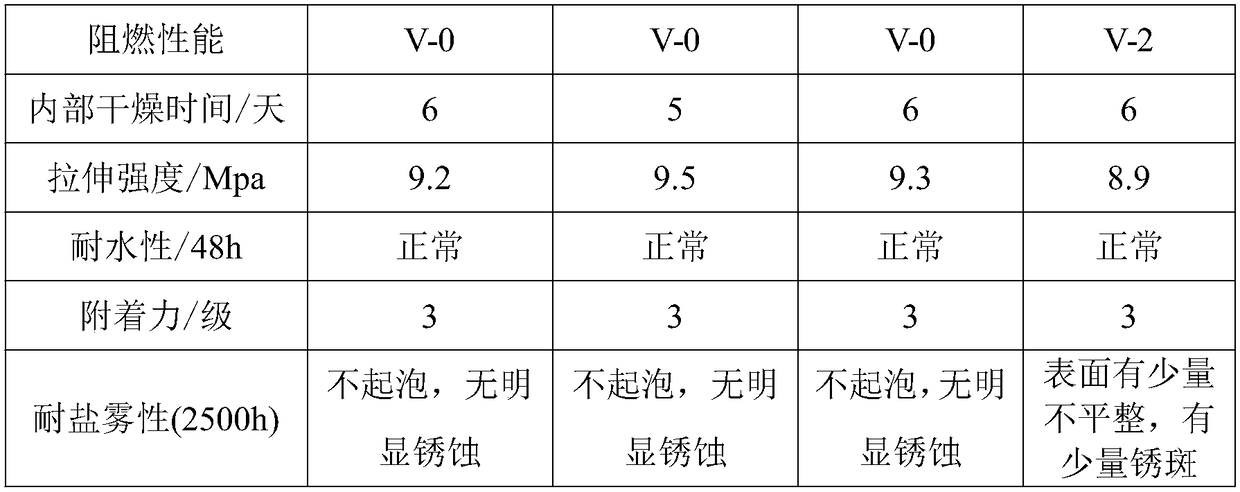

Embodiment 1

[0033] The environment-friendly flame-retardant and anti-corrosion coating of this embodiment is prepared from the following raw materials in parts by weight (kg): toluene diisocyanate 40, flame-retardant composite polyether polyol 380, fluorine-containing polyether polyol 140, polydimethylsiloxane 70 alkanes, 40 hexadecyl phosphate salts, 15 hydroquinone bis(β-hydroxyethyl) ethers, 10 polyvinylpyrrolidones, 5 silica powders, 50 sodium dihydrogen phosphates, 20 stannous octoates, and potassium polyacrylate 5 parts of powder, 40 parts of deionized water.

[0034] The preparation method of the environment-friendly flame-retardant anticorrosion coating of the present embodiment comprises the following steps:

[0035] Step 1: Take the mixed solution of flame-retardant composite polyether polyol and fluorine-containing polyether polyol and add it into a closed reaction kettle with a stirrer and a vacuum pump, evacuate to 0.1MPa, stir and remove water at 100°C for 120 minutes, and g...

Embodiment 2

[0041] The environment-friendly flame-retardant and anti-corrosion coating of this embodiment is formulated from the following raw materials in parts by weight (kg): hexamethylene diisocyanate 20, flame-retardant composite polyether polyol 200, fluorine-containing polyether polyol 100, polydimethyl Siloxane 50, Cetyl Phosphate Salt 10, Hydroquinone Bis(β-Hydroxyethyl) Ether 10, Polyvinylpyrrolidone 5, Silica Powder 1, Sodium Bicarbonate 30, Dibutyltin Dilaurate 10, 1 part of polyacrylic acid potassium salt dispersant, 20 parts of deionized water.

[0042] The preparation method of the environment-friendly flame-retardant anticorrosion coating of the present embodiment comprises the following steps:

[0043]Step 1: Take the mixed solution of flame-retardant composite polyether polyol and fluorine-containing polyether polyol and add it into a closed reaction kettle with a stirrer and a vacuum pump, evacuate to 0.1MPa, stir and remove water at 100°C for 120 minutes, and get Anhy...

Embodiment 3

[0049] The environmentally friendly flame-retardant anti-corrosion coating of this example is prepared from the following raw materials in parts by weight (kg): 4,4'-methylene-dicyclohexyl diisocyanate 40, flame-retardant composite polyether polyol 400, fluorine-containing polyol Ether polyol 150, polydimethylsiloxane 100, 16-chlorohexadecyl phosphate salt and cetyl phosphate salt in a ratio of 1:1 total 40, hydroquinone-bis(β-hydroxyethyl Base) ether 30, polyvinylpyrrolidone 20, silicon micropowder 10, sodium bicarbonate 60, triethanolamine 20, polyacrylic acid potassium salt dispersant 10 parts, deionized water 40 parts.

[0050] The preparation method of the environment-friendly flame-retardant anticorrosion coating of the present embodiment comprises the following steps:

[0051] Step 1: Take the mixed solution of flame-retardant composite polyether polyol and fluorine-containing polyether polyol and add it into a closed reaction kettle with a stirrer and a vacuum pump, ev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com