Degradable food packaging bag

A technology for packaging bags and food, applied in the field of degradable food packaging bags, can solve problems such as affecting the living environment and polluting the environment, and achieve the effect of improving environmental protection performance and rapid natural degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

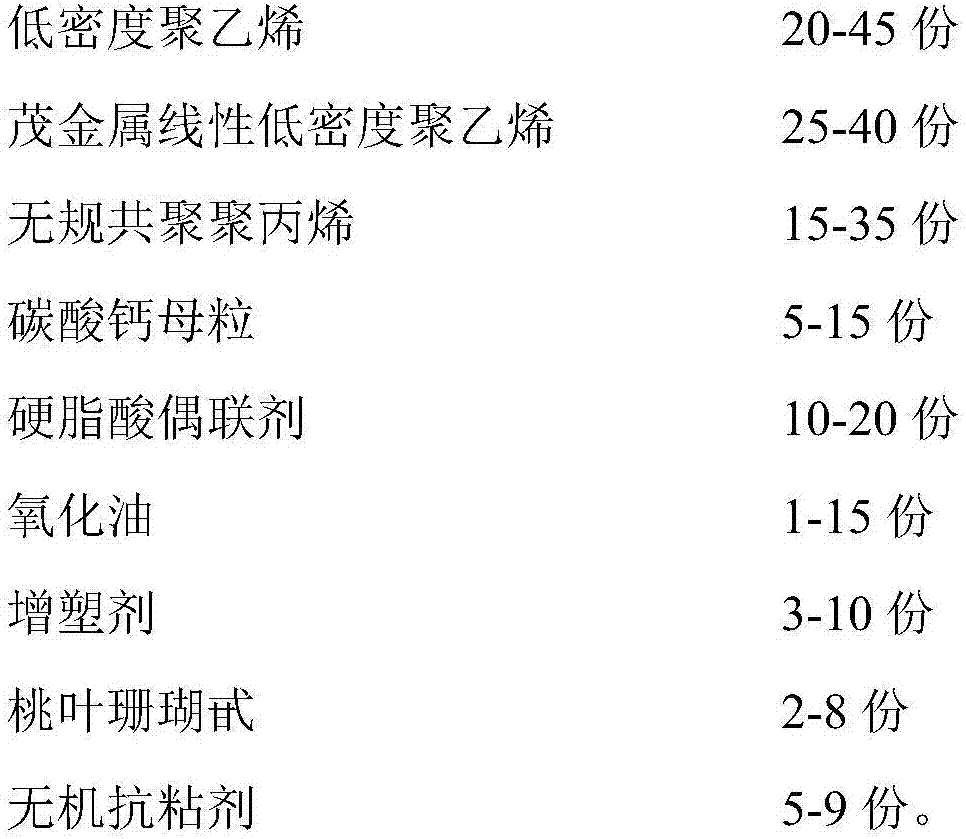

[0015] A degradable food packaging bag is made of the following components by weight:

[0016] 30 parts of low-density polyethylene, 35 parts of metallocene linear low-density polyethylene, 20 parts of random copolymer polypropylene, 12 parts of calcium carbonate masterbatch, 13 parts of stearic acid coupling agent, 10 parts of oxidized oil, 5 parts of plasticizer 6 parts, 6 parts of aucubin and 6 parts of inorganic anti-sticking agent.

[0017] The preparation method is a conventional blow molding process.

Embodiment 2

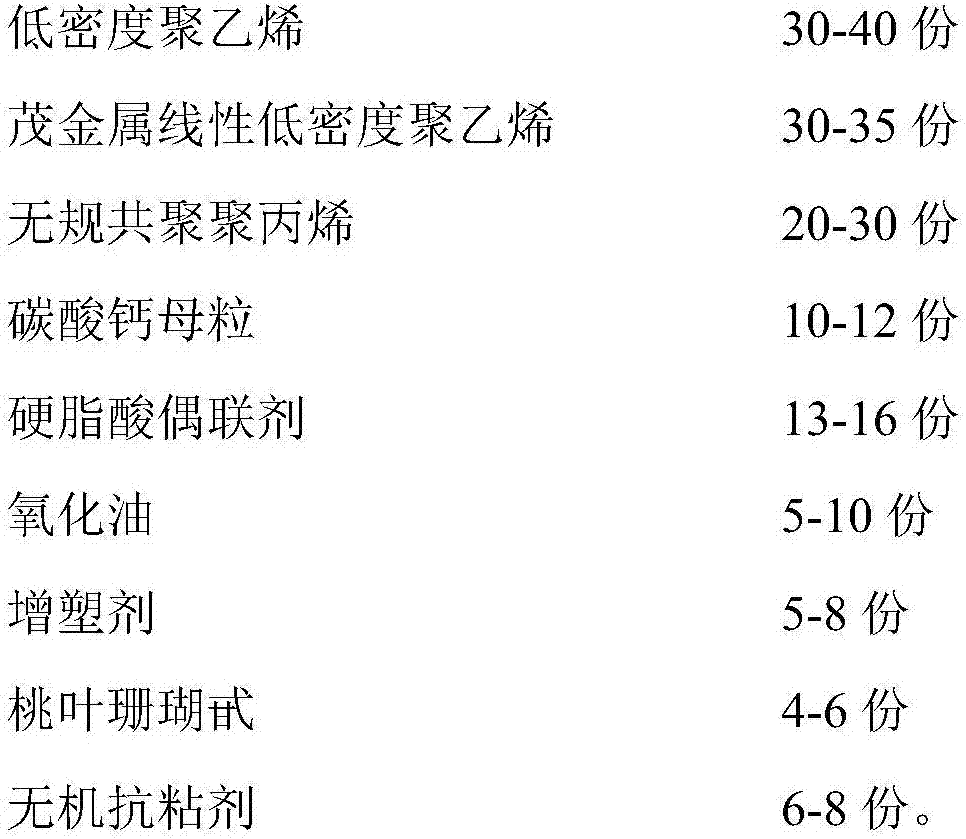

[0019] A degradable food packaging bag is made of the following components by weight:

[0020] 40 parts of low-density polyethylene, 30 parts of metallocene linear low-density polyethylene, 30 parts of random copolymerized polypropylene, 10 parts of calcium carbonate masterbatch, 16 parts of stearic acid coupling agent, 5 parts of oxidized oil, and 8 parts of plasticizer 4 parts, 4 parts of aucubin and 8 parts of inorganic anti-sticking agent.

[0021] The preparation method is a conventional blow molding process.

Embodiment 3

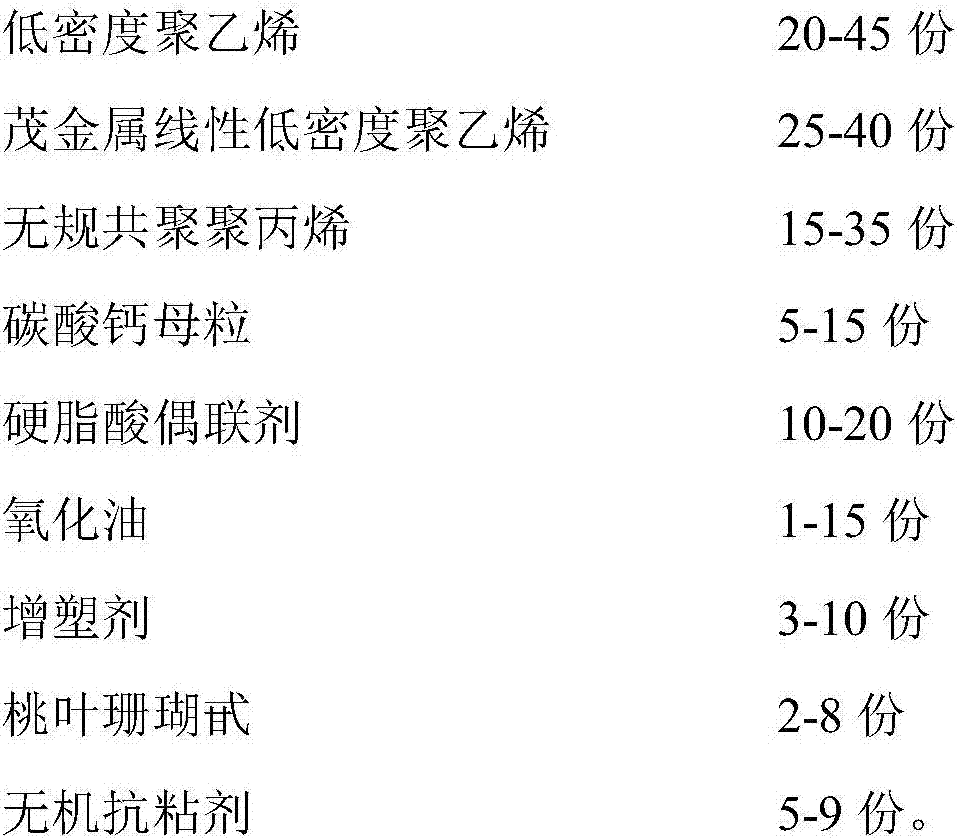

[0023] A degradable food packaging bag is made of the following components by weight:

[0024] 35 parts of low-density polyethylene, 32 parts of metallocene linear low-density polyethylene, 25 parts of random copolymer polypropylene, 11 parts of calcium carbonate masterbatch, 14 parts of stearic acid coupling agent, 8 parts of oxidized oil, 6 parts of plasticizer 5 parts, 5 parts of aucubin and 7 parts of inorganic anti-sticking agent.

[0025] The preparation method is a conventional blow molding process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com