Restaurant wastewater, oil-water and slag separation all-in-one machine

A technology for catering sewage and oil-water separation, which is applied in the fields of water/sewage multi-stage treatment, flotation water/sewage treatment, water/sludge/sewage treatment, etc. Tube blockage and other problems, to achieve the effect of long service life, high energy consumption and high heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

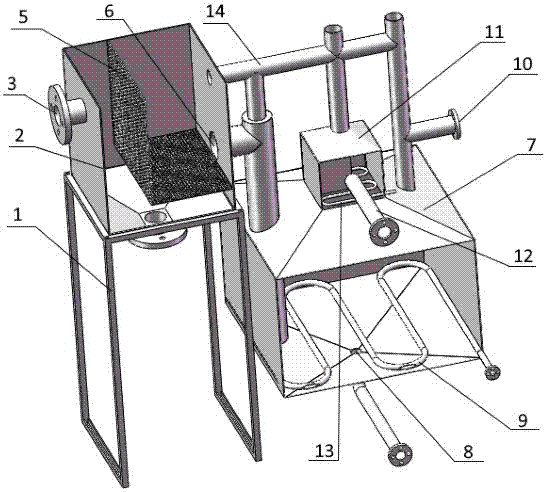

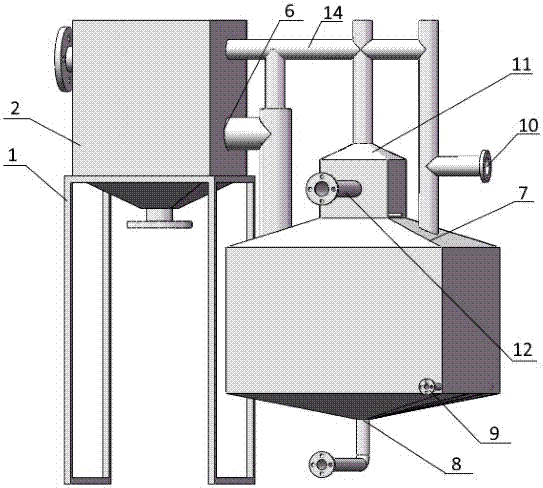

[0035] Such as Figure 1-2 As shown, an all-in-one machine for separating oil and water slag from catering sewage includes a solid-liquid separation part, an oil-water separation part and a ventilation pipeline; the solid-liquid separation part includes a bracket (1), a solid-liquid separation box (2), a sewage inlet ( 3), coarse slag outlet (4), solid-liquid separation sieve plate (5), oil-water overflow pipe (6), solid-liquid separation box (2) fixed on the bracket (1), sewage inlet (3), coarse slag outlet (4) and the oil-water overflow pipe (6) are respectively arranged at the upper, bottom and middle positions in the solid-liquid separation box (2) according to a certain height difference; the solid-liquid separation sieve plate (5) is divided into a vertical plate and a bottom plate and formed into an L shape It is fixedly connected with the side plate and top plate of the solid-liquid separation box (2) to form a cavity for retaining oil and water. The inlet of the oil-w...

Embodiment 2

[0042] Below in conjunction with embodiment 1 and appended figure 1 The optimization or / and improvement provided by the present invention is further described:

[0043] The solid-liquid separation sieve plate (5) is divided into two connected vertical plates and a bottom plate, and the two vertical plates are connected at right angles and are respectively fixedly connected to the bottom plate in an L shape.

[0044] The grease collection chamber (11) is provided with a temperature controller, and the automatic constant temperature control of the grease in the grease collection chamber (11) is realized by controlling the grease heater (13).

[0045] The integrated machine for separating oily water and slag from catering sewage also includes an industrial control computer, a signal acquisition device, a signal execution device and a monitoring display screen.

[0046] The industrial control computer is a PLC programmable controller; the signal acquisition device is a liquid lev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com