Preparation method of porous cerium-based composite oxide

A composite oxide, cerium-based technology, which is applied in the preparation of alumina/hydroxide, chemical instruments and methods, rare earth metal oxide/hydroxide, etc., achieves easy availability of raw materials, high yield, and simple and reliable preparation method. control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

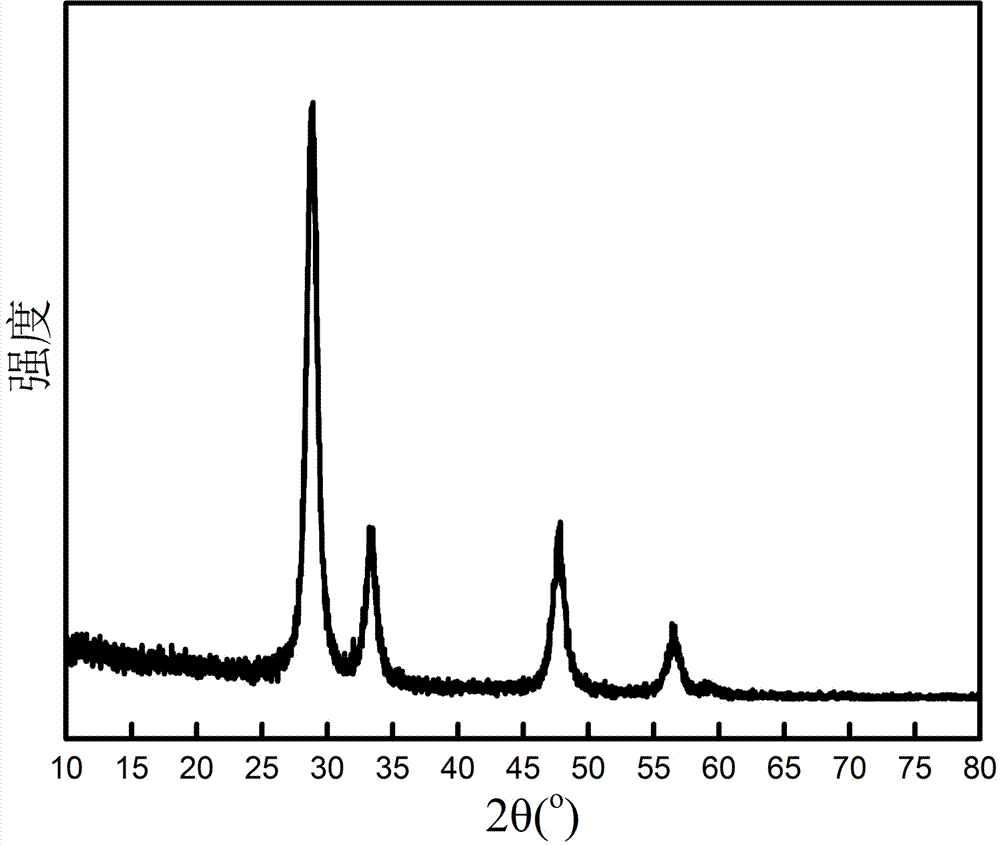

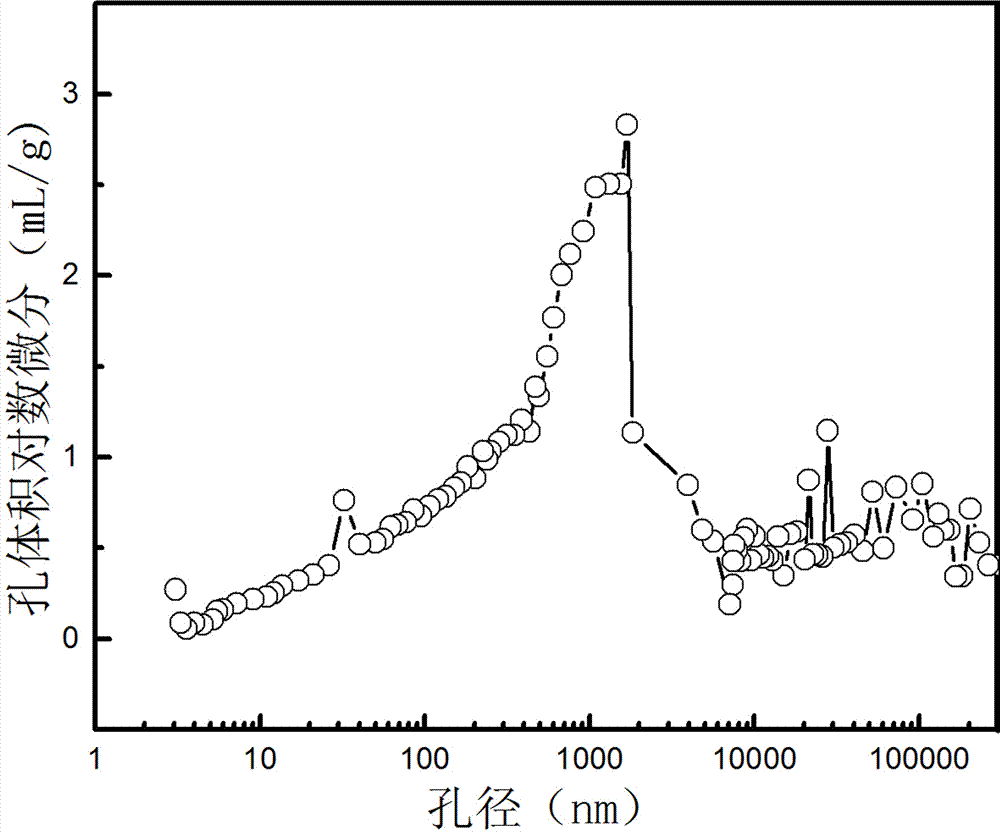

[0023] Weigh 4.34g of cerium nitrate and 2.15g of zirconium nitrate and dissolve them in 100mL of deionized water, then add 4.20g of citric acid, stir magnetically for 0.5 hours until the solution is colorless and transparent; add 1.82g of cetyltrimethylammonium bromide, Stir magnetically for 1 hour, add 45 mL of absolute ethanol, and continue magnetically stirring for 0.5 hour; place it in a constant temperature oven at 80°C, and let it stand for 12 hours to obtain a foam product; place the porous foam product in a muffle furnace, Calcined at 500°C for 6 hours under the atmosphere, and obtained porous cerium-zirconium composite oxide after cooling in the furnace. The X-ray diffraction spectrogram of this porous cerium-zirconium composite oxide and standard card JCPDS 38-1439 (Ce 0.6 Zr 0.4 o 2 ) coincides with the characteristic peaks; the average pore diameter of the macropores of the porous cerium-zirconium composite oxide measured by mercury porosimetry is 0.8 μm, and th...

Embodiment 2

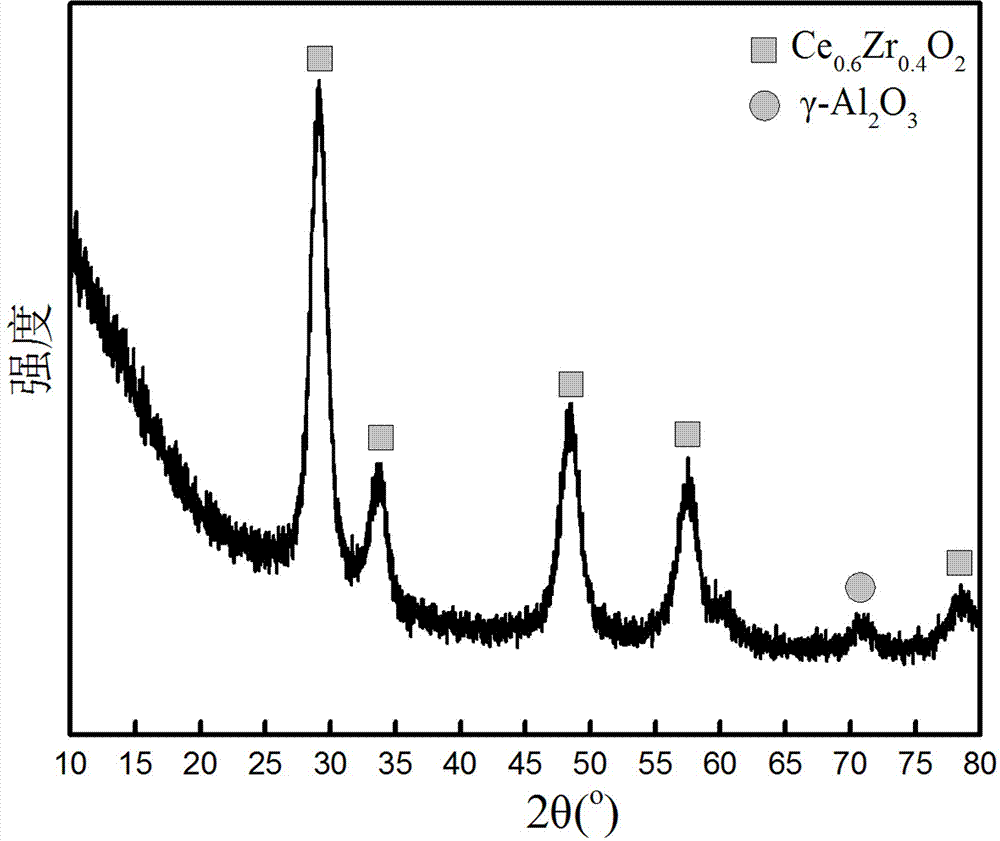

[0025] Weigh 4.34g of cerium nitrate, 2.15g of zirconium nitrate, and 13.10g of aluminum nitrate and dissolve them in 100mL of deionized water, then add 10.50g of citric acid, stir magnetically for 0.5 hours until the solution is colorless and transparent; add 5.46g of hexadecyltrimethyl ammonium bromide, magnetically stirred for 1 hour, added 50mL of absolute ethanol, and continued to magnetically stir for 0.5 hours; placed in a constant temperature oven at 80°C, and left to stand for 12 hours to obtain a foam product; place the foam product in a muffle furnace , calcined at 500°C for 6 hours in an air atmosphere, and obtained porous cerium-based composite oxides after cooling with the furnace. The XRD spectrum shows that the porous cerium-based composite oxide is a porous cerium-zirconium-aluminum composite oxide; the porous cerium-zirconium-aluminum composite oxide has an average pore diameter of 1.5 μm and a porosity of 82.27% as measured by mercury porosimetry ; The speci...

Embodiment 3

[0027] Weigh 4.34g of cerium nitrate and 2.15g of zirconium nitrate and dissolve them in 100mL of deionized water, then add 13g of pseudoboehmite and 10.50g of citric acid, and stir magnetically for 0.5 hours; then add 5.46g of hexadecyl trimethyl bromide ammonium, add 50mL of absolute ethanol after magnetic stirring for 1 hour, continue magnetic stirring for 0.5 hours, and then place it in a constant temperature oven at 80°C; let it stand for 12 hours to obtain a foam product; place the foam product in a muffle furnace, in the air Calcined at 500°C for 6 hours under the atmosphere, and obtained porous cerium-based composite oxide after cooling in the furnace. The porous cerium-based composite oxide is a porous cerium-zirconium-aluminum composite oxide; the mesoporous BET specific surface area of the porous cerium-zirconium-aluminum composite oxide is 134m 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com