Novel graphene thin film transferring method and preparation method of sensor

A graphene film and graphene composite technology, applied in the field of graphene, can solve the problems of PMMA film wrinkles, graphene damage, resin layer cannot be removed, etc., and achieve the effect of reducing operation difficulty, low price and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] A method for preparing a sensor, comprising: making a channel electrode on the surface of the graphene film prepared by the above method, making the graphene film into a pattern of a touch sensor, attaching optical glue to the surface of the patterned graphene film and then packaging it. Degassing treatment.

[0030]Graphene film is made by using the above-mentioned method of transferring graphene film. Graphene is a super-strong aluminum compound with a honeycomb structure, flexible and more conductive than silicon. The graphene film obtained by the above method is complete, basically It is non-destructive and has a large area, so the use of the graphene film in the production of sensors can enable the sensor to generate stronger electrical signals.

Embodiment 1

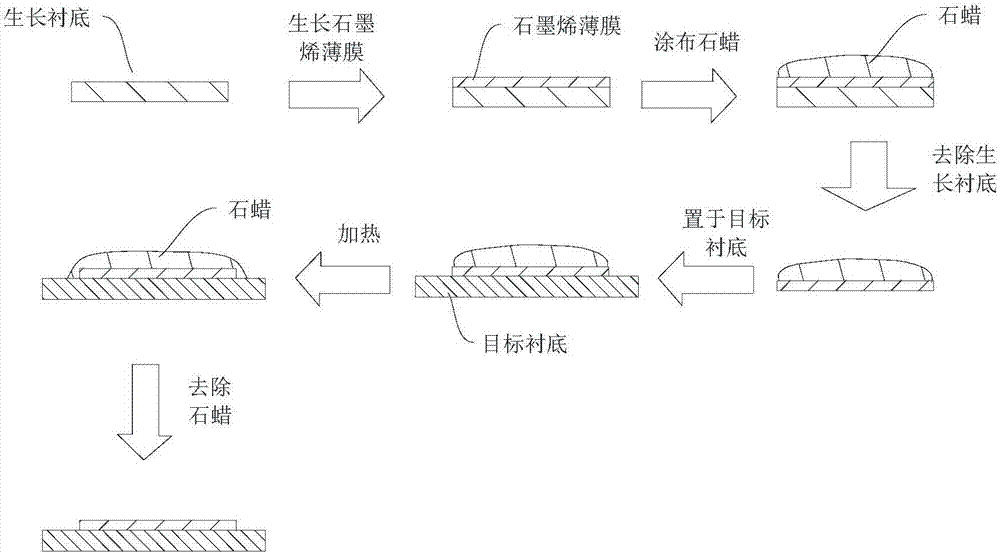

[0033] A novel method for transferring a graphene film, comprising: growing a graphene film by CVD on the surface of a copper foil with a thickness of 30 μm. After the growth is completed, melted paraffin is coated on the surface of the graphene film, and the copper foil substrate is further heated to make the paraffin evenly distributed on the surface of the copper foil, wherein the thickness of the paraffin is about 2 mm. After the paraffin is solidified, the copper foil substrate is etched away by chemical etching, and then the graphene surface of the paraffin / graphene composite film is placed on the surface of the silicon wafer. The silicon wafer was heated for 1 min at a temperature of 70° C. to adhere the paraffin wax to the surface of the silicon wafer. Then dissolve the paraffin with xylene, and clean the silicon wafer to completely remove the paraffin, and the transfer of the graphene film is basically completed without damage.

Embodiment 2

[0035] A novel method for transferring a graphene film, comprising: growing a graphene film on the surface of a nickel foil with a thickness of 50 μm by CVD. After the growth is completed, melted paraffin is coated on the surface of the graphene film, and the nickel foil substrate is further heated to make the paraffin evenly distributed on the surface of the nickel foil, wherein the thickness of the paraffin is about 1mm. After the paraffin is solidified, the nickel foil substrate is etched away by electrochemical corrosion, and then the graphene surface of the paraffin / graphene composite film is placed on the surface of the silicon wafer. The silicon wafer was heated for 1 min at a temperature of 70° C., so that the paraffin wax was completely adhered to the surface of the silicon wafer. Then the paraffin was dissolved with xylene, and the silicon wafer was cleaned to completely remove the paraffin, so that the transfer of the graphene film was basically completed without da...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com