Wire cutting wire arrangement mechanism with electrode wire cutting and recovery functions

A technology of wire cutting and electrode wire, which is applied in the direction of electrode manufacturing, electric processing equipment, accessory devices, etc., can solve the problems of long hours and energy of operators, and achieve the effects of convenient and flexible operation, improved processing efficiency, and stable wire tightening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

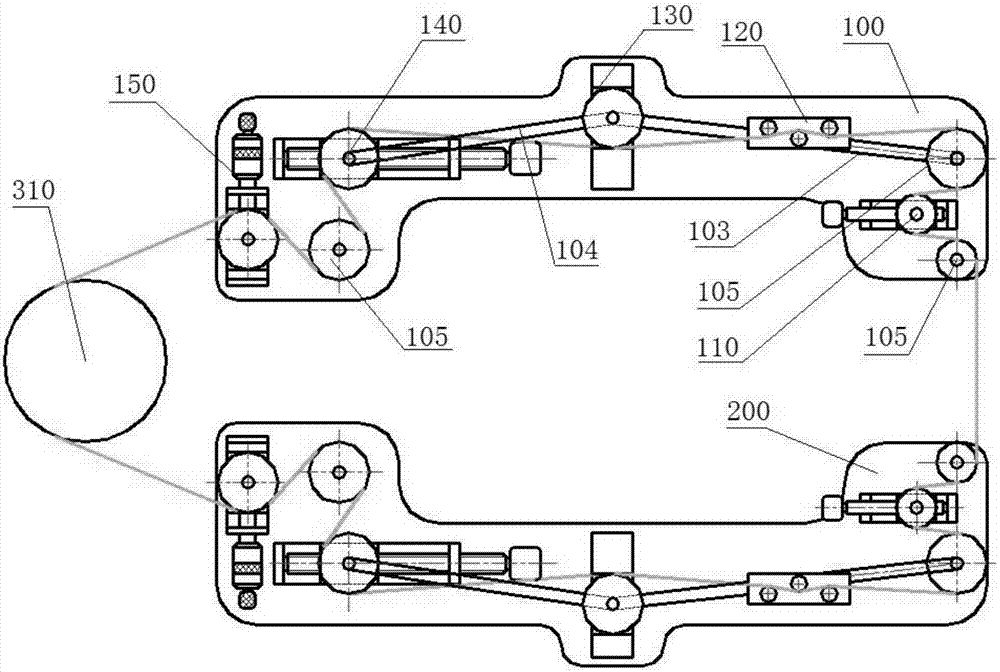

[0037] combine figure 1 , the present invention proposes a wire-cutting wire-feeding mechanism with the function of cutting and recovering the electrode wire, which includes a wire drum mechanism 310 and a wire-discharging mechanism, and the wire-discharging mechanism includes two sets of connecting rod combination mechanisms arranged as mirror images on the same plane; Two groups of connecting rod combination mechanisms are respectively fixedly arranged on the upper and lower wire arms. When in use, the upper wire arm 100, the lower wire arm 200 and the wire drum mechanism 310 are all fixedly arranged on the wire cutting machine bed.

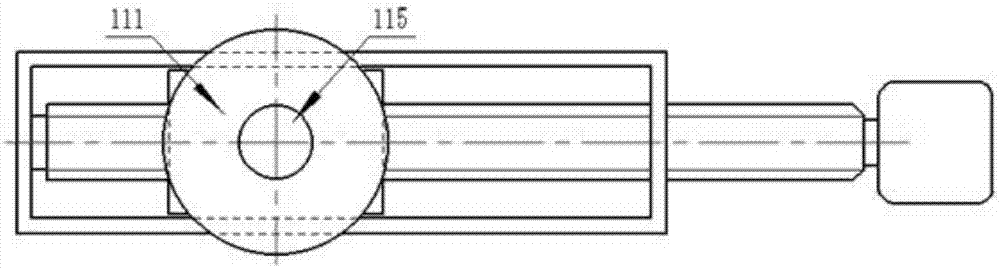

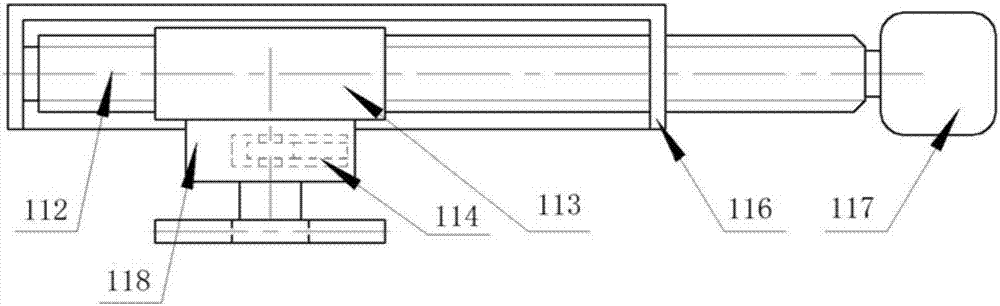

[0038] The connecting rod combination mechanism includes a manual wire tightening mechanism, an automatic wire tightening mechanism, a sliding mechanism and several fixed guide wheels for changing the direction of wire discharge arranged in the same plane for the electrode wire to pass through. The number and order of the above-mentioned mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com