Electrostatic spinning-based pressure-sensitive adhesive patch, and preparation method thereof

A pressure-sensitive adhesive patch and electrospinning technology, which is applied in the direction of electrospinning, rayon manufacturing, and medical preparations of non-active ingredients, can solve problems such as poor adhesion, and achieve high porosity and drug utilization. High, good air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] (1) 80 parts by weight of SIS thermoplastic elastomer, 80 parts by weight of petroleum resin, 10 parts by weight of propylene glycol, 50 parts by weight of oleanolic acid and 2 parts by weight of N,N-dibutylamino disulfide Zinc formate is fully dissolved in a mixed solvent of tetrahydrofuran, cyclohexane and gasoline (wherein the mass ratio of tetrahydrofuran to cyclohexane and gasoline is 2:1:1), and the preparation of a spinning solution with a solid concentration of 16wt% .

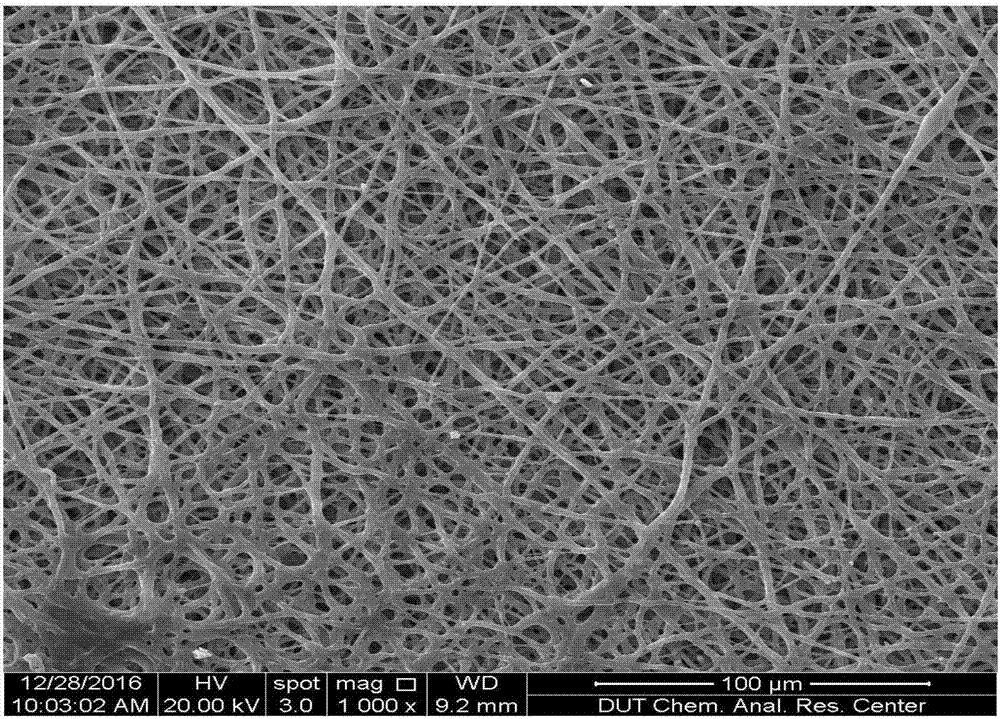

[0038] (2) Put the above-mentioned spinning solution into a syringe, place it on an electrospinning device for spinning, and obtain the drug-loaded SIS hot-melt pressure-sensitive adhesive fiber film, and its structure is as follows: figure 1 shown. The spinning collection method is flat plate collection or drum collection. The surface of the receiving flat plate or drum is pasted with a backing material, and the receiving thickness is 200±20 μm. After collection, the backing material is added ...

Embodiment 2

[0040] (1) 80 parts by weight of polyethylene oxide, 10 parts by weight of propylene glycol and 2 parts by weight of N,N-zinc dibutylcarbamate in a mixed solvent of water and ethanol (wherein water and ethanol The mass ratio is 3:7), and the spinning solution with a solid concentration of 7wt% is prepared.

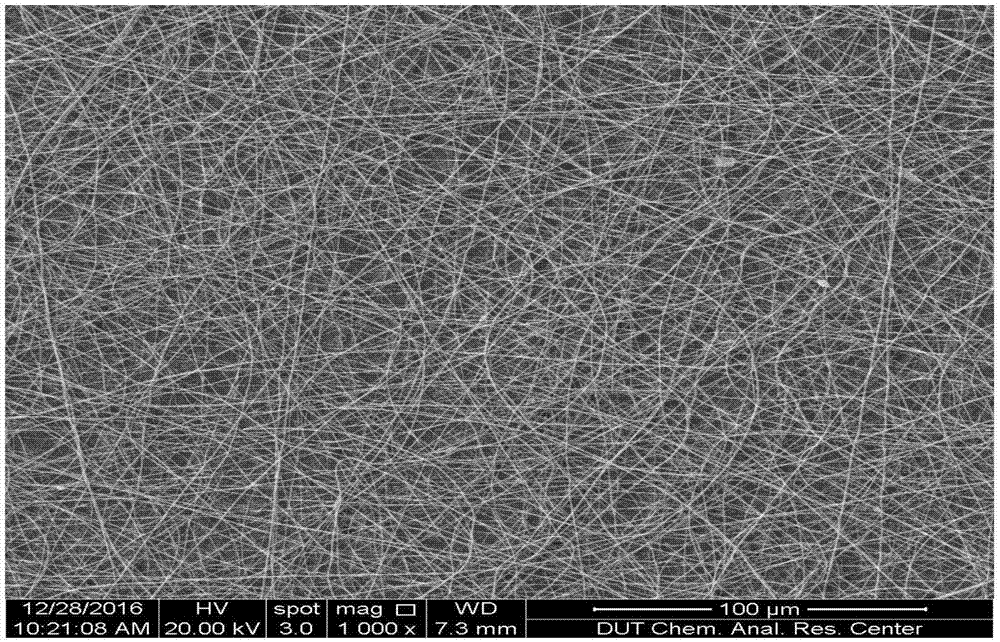

[0041] (2) Put the above-mentioned spinning solution into a syringe, and place it on an electrospinning device for spinning to obtain a polyethylene oxide fiber membrane, the structure of which is as follows: figure 2 shown. The collection method of spinning is flat plate collection or drum collection, and the surface of the receiving flat plate or drum is pasted with a backing material, and the receiving thickness is 200±20μm. After collection, the backing material is added to obtain a polyethylene oxide fiber membrane blank patch . Electrospinning parameters: voltage 15kv, spinning speed 1ml / h, receiving distance 20cm, relative humidity 30%.

Embodiment 3

[0043](1) 80 parts by weight of polyethylene oxide, 50 parts by weight of geniposide, 10 parts by weight of propylene glycol and 2 parts by weight of N,N-dibutylcarbamate zinc, in water and ethanol fully dissolved in a mixed solvent (wherein the mass ratio of water and ethanol is 3:7), and a spinning solution with a solid concentration of 10wt% was prepared.

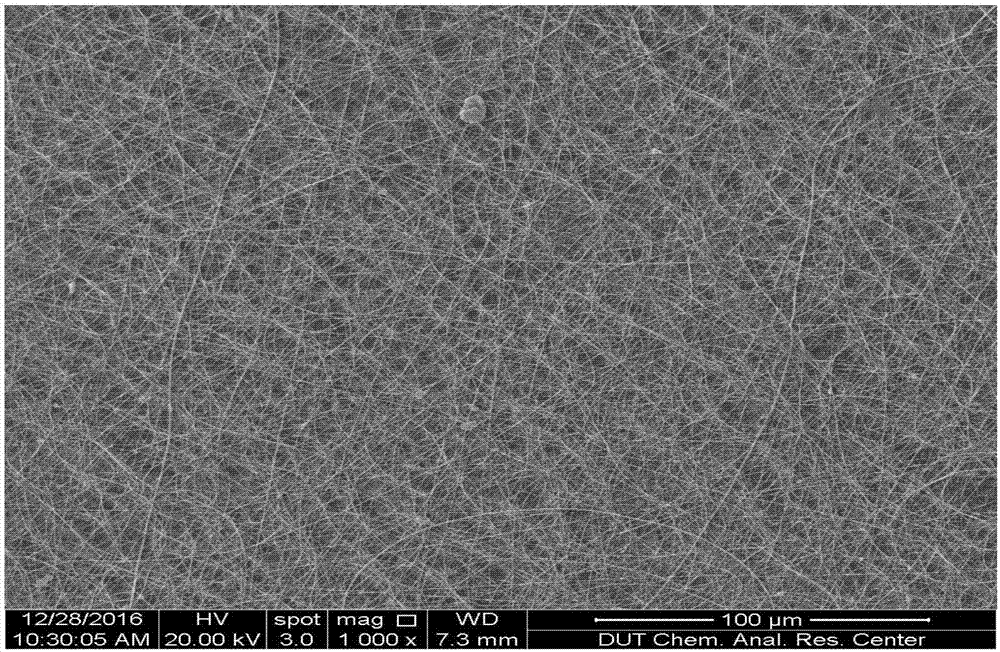

[0044] (2) Put the above-mentioned spinning solution into a syringe and place it on an electrospinning device for spinning to obtain a drug-containing nanofiber membrane, the structure of which is as follows: image 3 shown. The collection method of spinning is flat plate collection or drum collection. The surface of the receiving plate or drum is pasted with backing material, and the receiving thickness is 200±20μm. After collection, the backing material is added to obtain the hydrophilic fiber membrane drug-containing external patch . Electrospinning parameters: voltage 15kv, spinning speed 1.0ml / h, receiving distanc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com