Semiconductor laser

A laser and semiconductor technology, applied in the field of lasers, can solve the problems of power drop, damage to the light-emitting point, poor uniformity of the spot distribution, etc., to achieve the effect of increasing the energy area and preventing internal damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

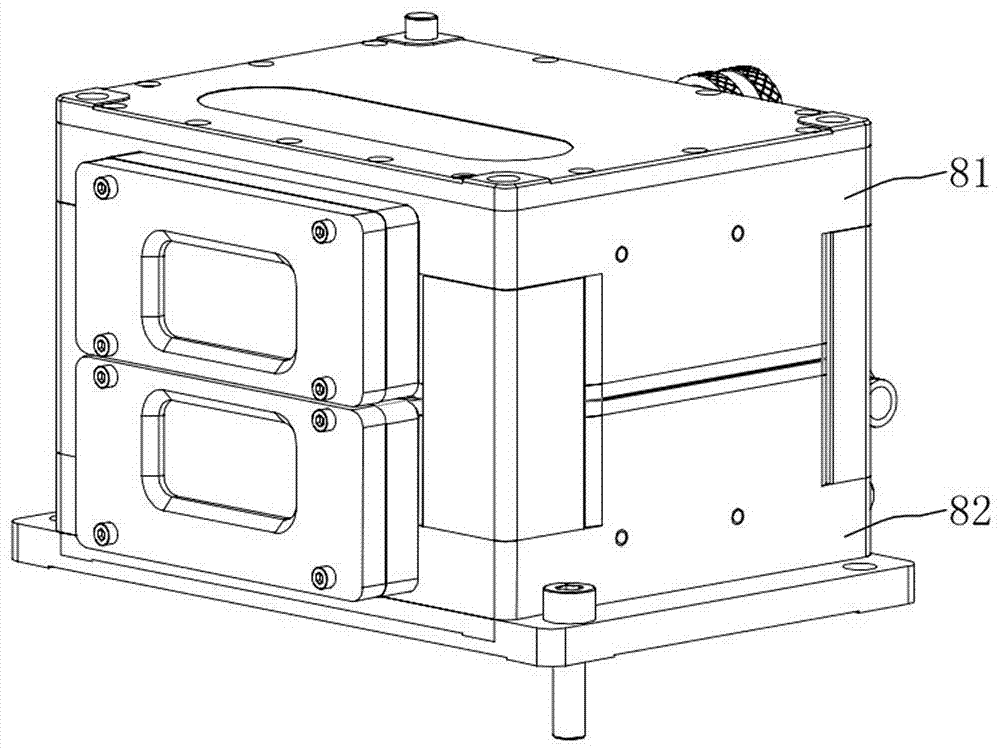

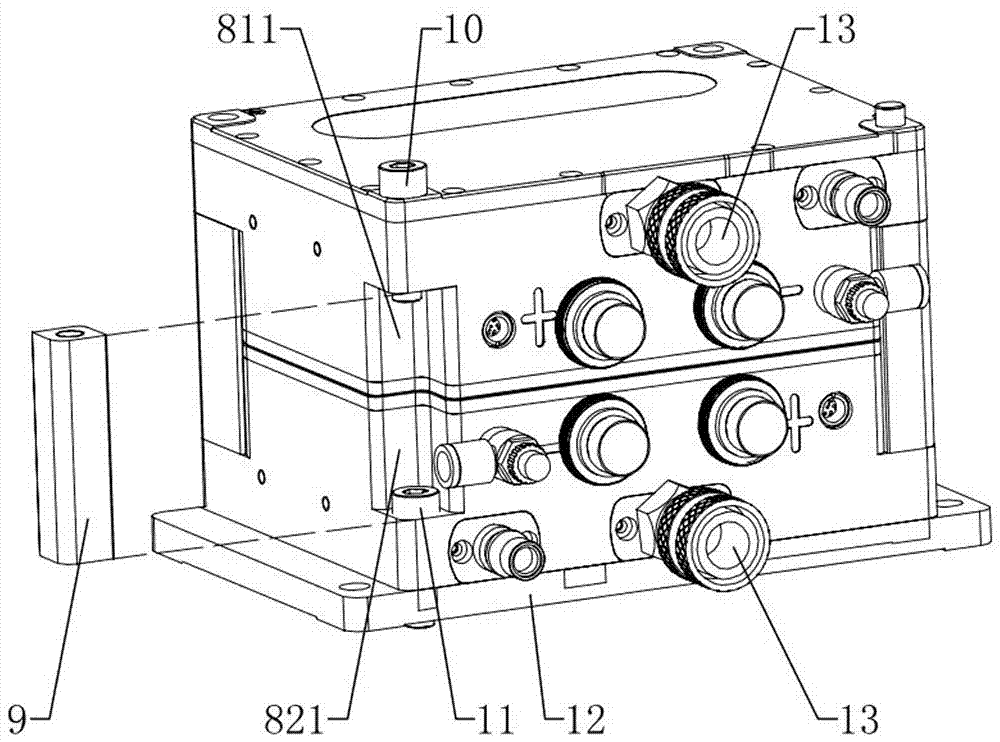

[0028] The above and other technical features and advantages of the present invention will be clearly and completely described below in conjunction with the accompanying drawings. Apparently, the described embodiments are only some of the embodiments of the present invention, not all of them.

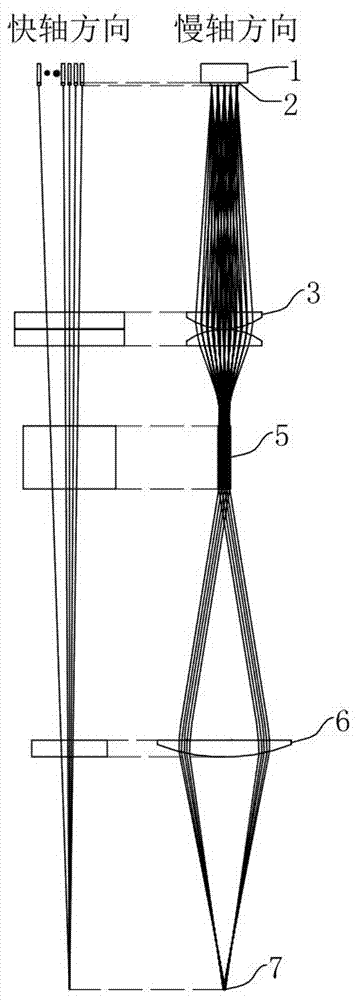

[0029] refer to figure 1 , the semiconductor laser provided by the present embodiment includes a BAR bar 1, an FAC mirror 2, a focusing lens group 3, a waveguide plate 5, and an imaging lens 6 arranged sequentially in the direction of the slow axis; the BAR bar 1 here is used to provide the original laser beam ; The FAC mirror 2 here is located on the surface of the BAR bar 1, and is used to collimate the original laser beam to output a quasi-parallel beam; the focusing lens group 3 here is used to focus the collimated beam, and in the direction of the slow axis The focal point is formed on the top; the waveguide plate 5 here is located at the position of the focal point, and is used to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com