Method and system for filling underground goaf by filling material slurry prepared from weathering pit sand

A technology for filling slurry and goaf, which is applied in the fields of filling, mining equipment, earthwork drilling, etc., can solve the problems of complex process, large investment, high cost of tailings cementation and filling, and achieves simple process flow, low investment, and high cost. Environmentally friendly effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

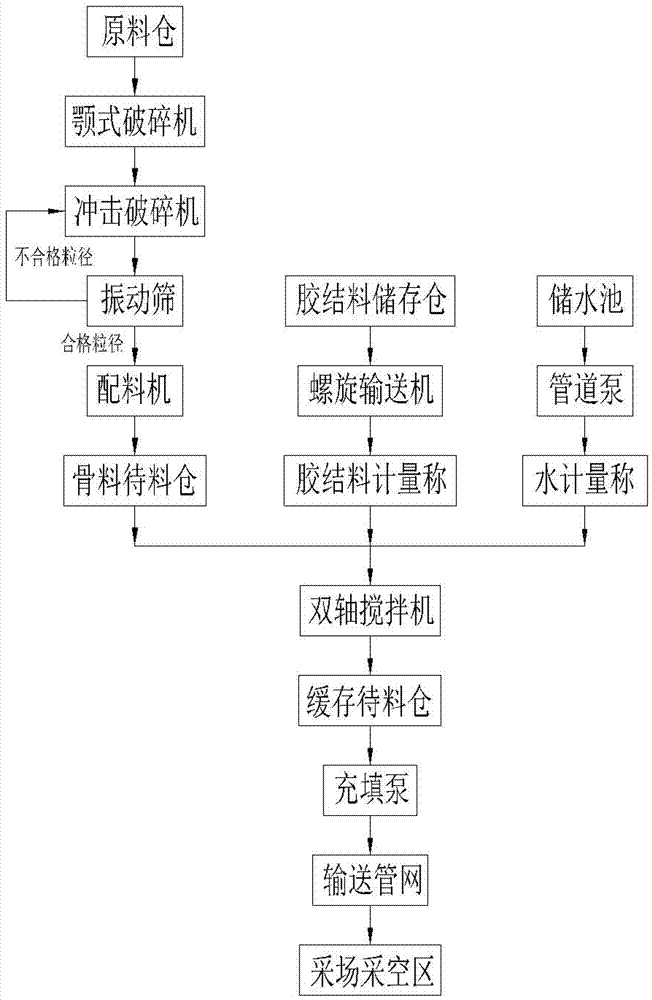

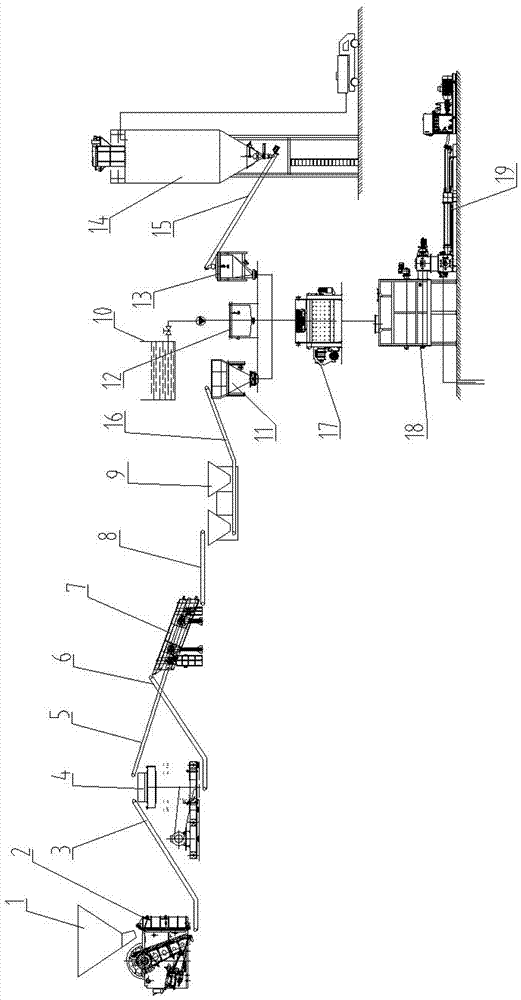

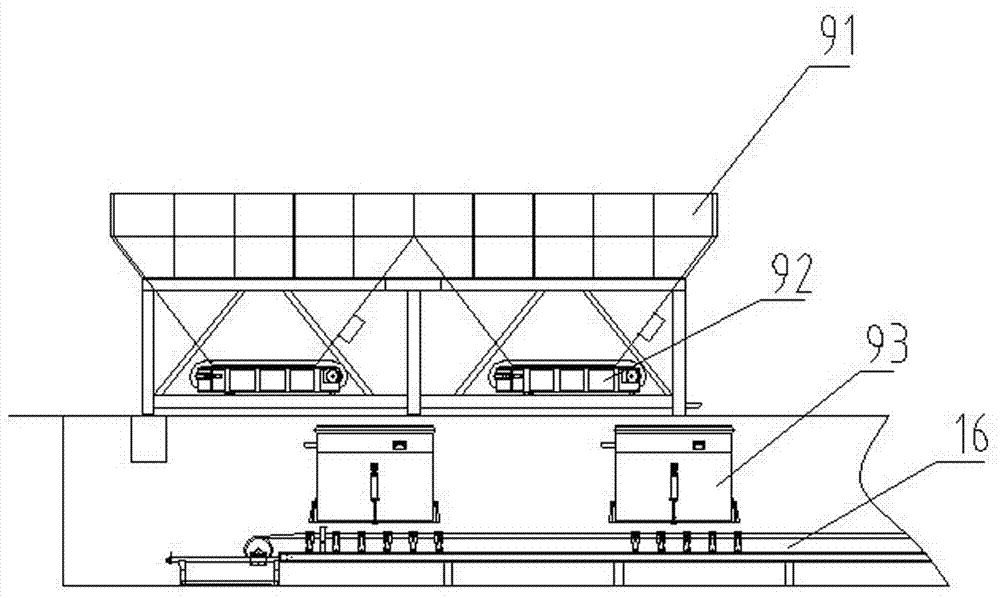

[0027] like figure 2 As shown, the filling system disclosed in this embodiment using weathered mountain sand to prepare filling slurry has a design capacity of 80m³ / h, and the main equipment includes: jaw crusher, impact crusher, vibrating screen, and 10m³ batching machine (including 1.5m³ measuring bucket), 800mm wide belt conveyor, 3m³ aggregate buffer warehouse, 1.5m³ cement weighing scale, 1.5m³ water measuring scale, 3m³ forced twin-shaft mixer, Φ273mm screw conveyor, 200t cement silo, 30m³ square buffer storage bin, ZBG120 / 8 high-pressure filling pump (pumping flow rate 120m³ / h, outlet pressure 8MPa).

[0028] The batching of filling slurry in this embodiment is determined:

[0029] The proportion of qualified mountain sand is 2.62 t / m³, the particle size is -10mm weathered mountain sand sample, the content of particles below 0.074mm is less than 10%, the cumulative content of particles below 2mm is between 79% and 87%, and the content of particles below 0.5mm The acc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com