System and control method for liquid slag dry type centrifugal pelletizing and waste heat recycling

A liquid slag and waste heat recovery technology, applied in the field of blast furnace slag waste heat recovery, can solve problems such as large water resources, consumption, environmental pollution, etc., and achieve the effect of improving the level of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

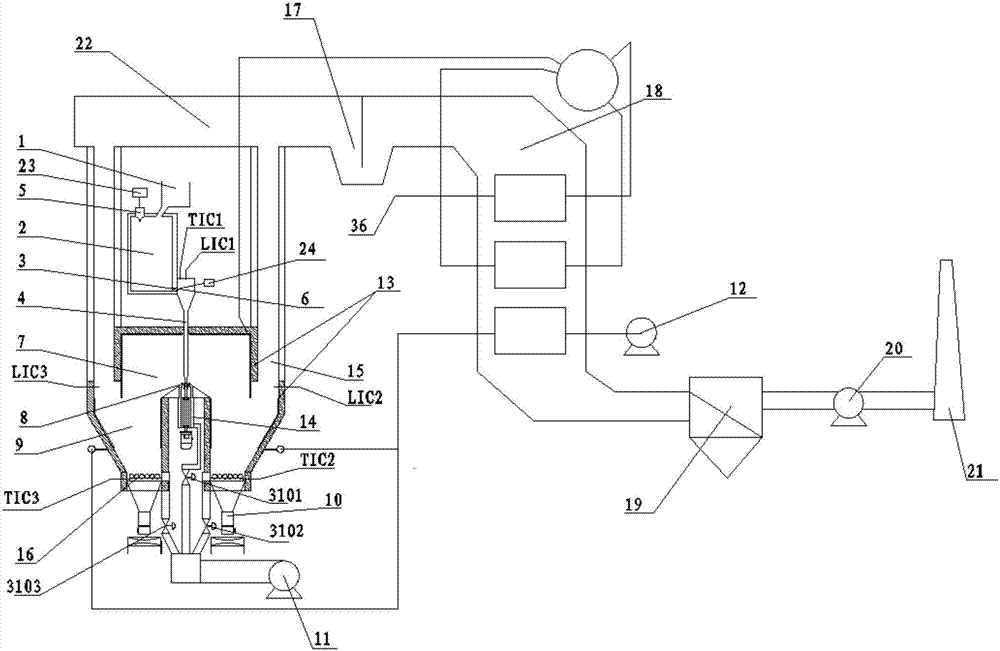

[0038] refer to Figure 1 to Figure 5 , The system for dry centrifugal granulation of liquid slag and waste heat recovery mainly includes: liquid slag drainage unit, liquid slag buffer and flow control unit, liquid slag granulation and waste heat recovery unit, waste heat utilization unit.

[0039] The liquid slag drainage unit mainly includes a slag ditch 1 and a baffle; the slag ditch inlet is connected to the blast furnace slag outlet, the baffle is located at the bottom of the slag ditch 1, and the slag ditch outlet is connected to the slag buffer device 2 inlet.

[0040] Liquid slag buffer and flow control unit, including slag buffer device 2, stopper rod 3, slag drop pipe 4 and afterburning burner 5; the bottom of the side wall of the slag buffer device 2 is provided with one or more slag outlets 6 , the liquid slag flows out from the slag outlet 6 and enters the corresponding slag fall pipe 4; the supplementary combustion burner 5 is arranged on the top of the slag buff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com