An equipment for repairing paint on the outer surface of a paint spraying pipe

A technology for the outer surface and paint spraying tubes, which is applied in the direction of spraying paint booths and spraying devices. It can solve the problems of easy damage to the painted surface of steel pipes, affect the health of workers, and affect the quality of spraying, so as to improve the quality of spraying, improve the anti-corrosion effect, and avoid spraying. The effect of dead ends

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

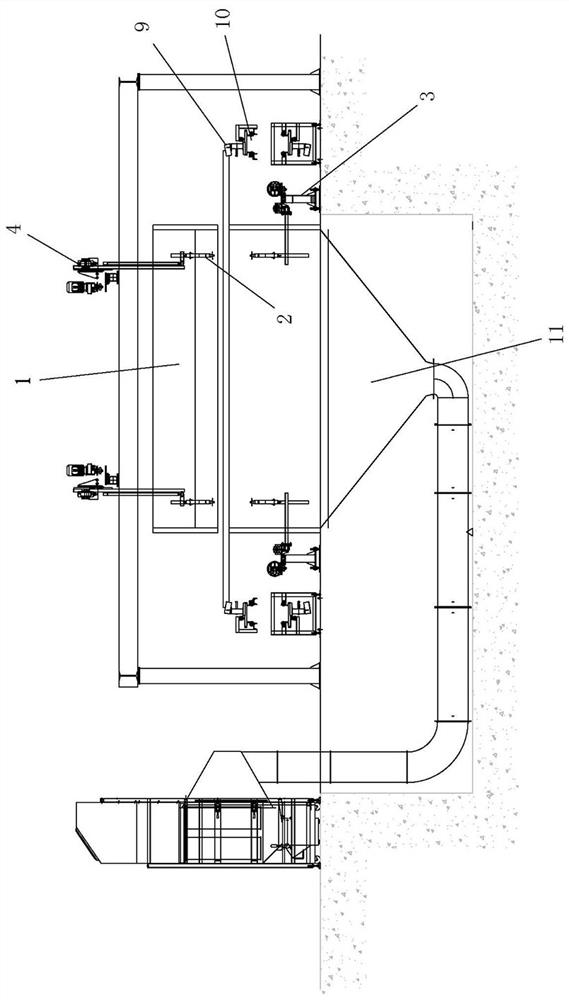

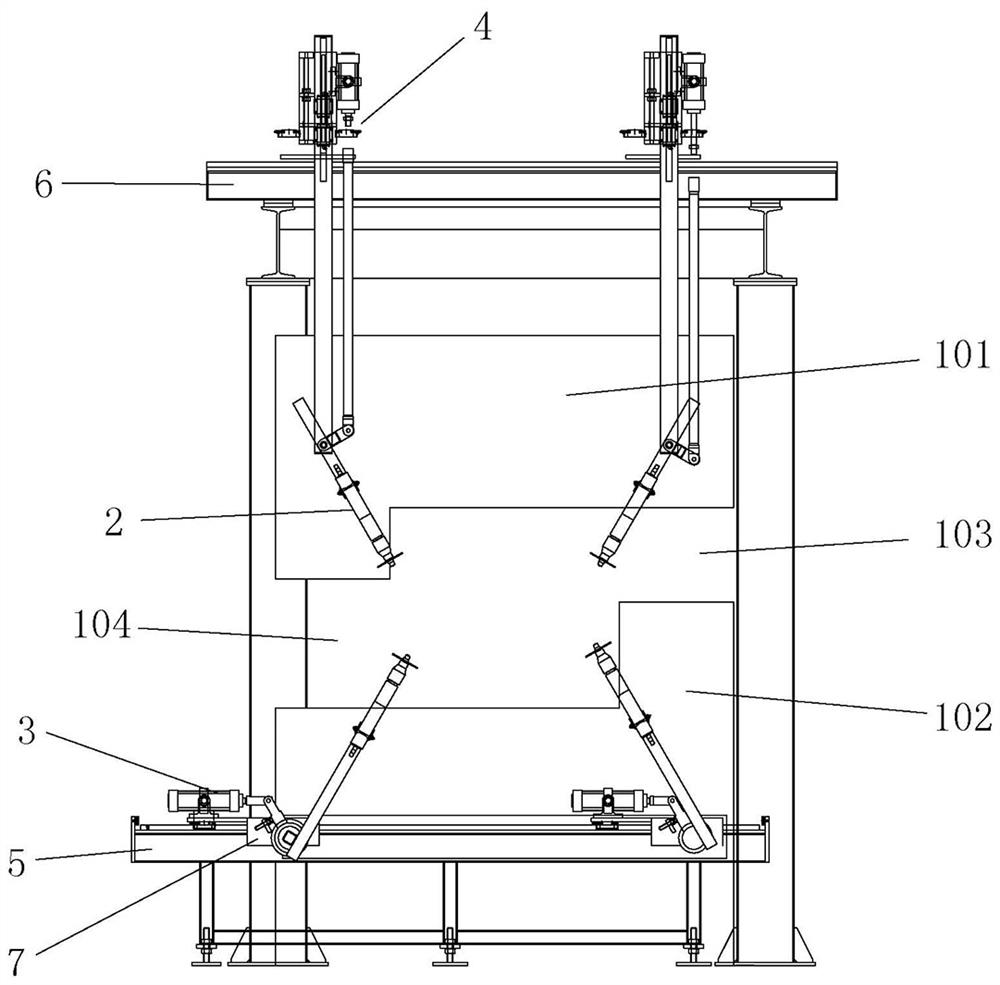

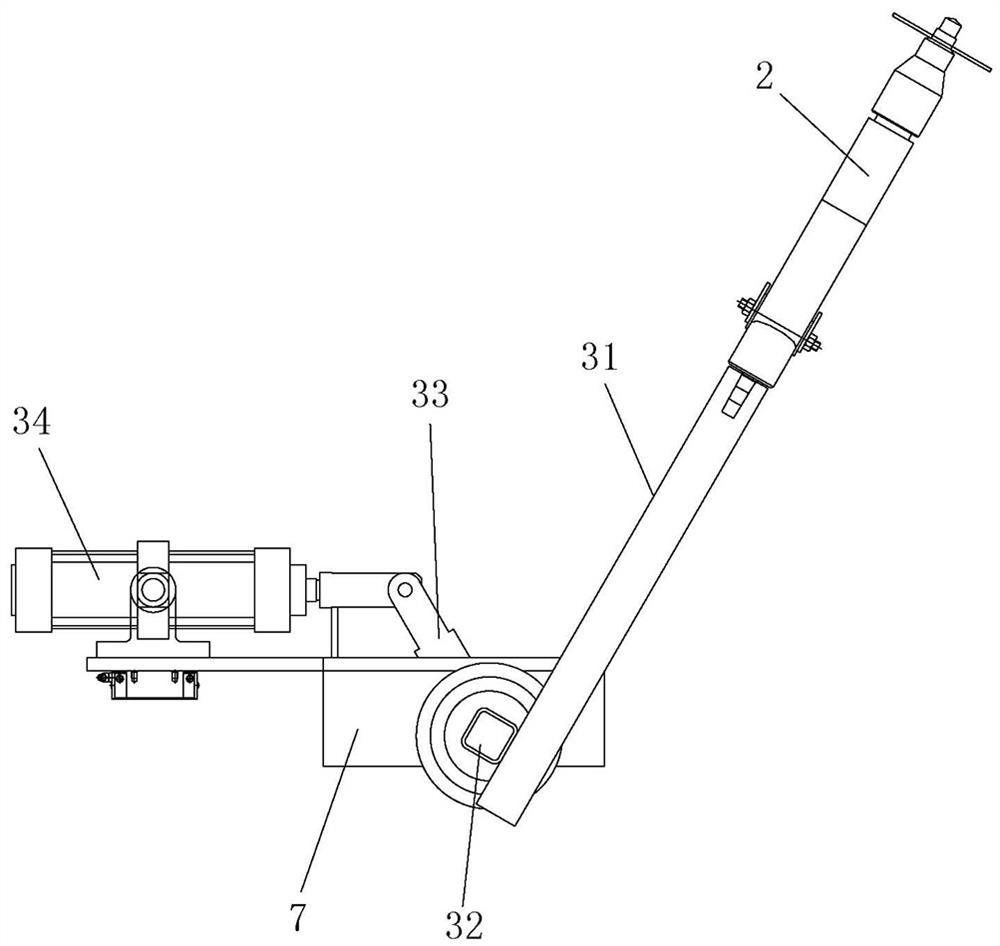

[0023] Example: as figure 1 and figure 2 As shown, a paint repairing equipment for the outer surface of a paint spraying pipe includes a paint repairing room 1 , a paint repairing device and a pipe fitting support 9 . The paint repairing room 1 includes a painting room 101 and a lower painting room 102 arranged up and down. A horizontally arranged input channel 103 and an output channel 104 are formed between the painting room 101 and the lower painting room 102. The output channel The height of 104 is lower than the height of the input channel 13, the input channel 103 communicates with the output channel 104, the pipe bracket 9 is arranged in the output channel 104, and the pipe bracket 9 is connected with a circulating conveying device 10. The circulating conveying device 10 adopts a circulating chain, and the pipe bracket 9 is installed on the chain link of the circulating chain, so that the pipe bracket 9 can move in the output channel 104 cyclically.

[0024] A recov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com