Method for testing greenhouse gas emission of indoor culture soil

A technology for cultivating soil and greenhouse gases, which is applied in the field of greenhouse gas monitoring and research, can solve the problems of being unable to maintain the natural concentration gradient of the soil-bottom atmosphere interface, difficult to describe the release of soil gas, and interfering with the emission of soil gas in cultivation, achieving low price, Easy and fast operation, the effect of halving the workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

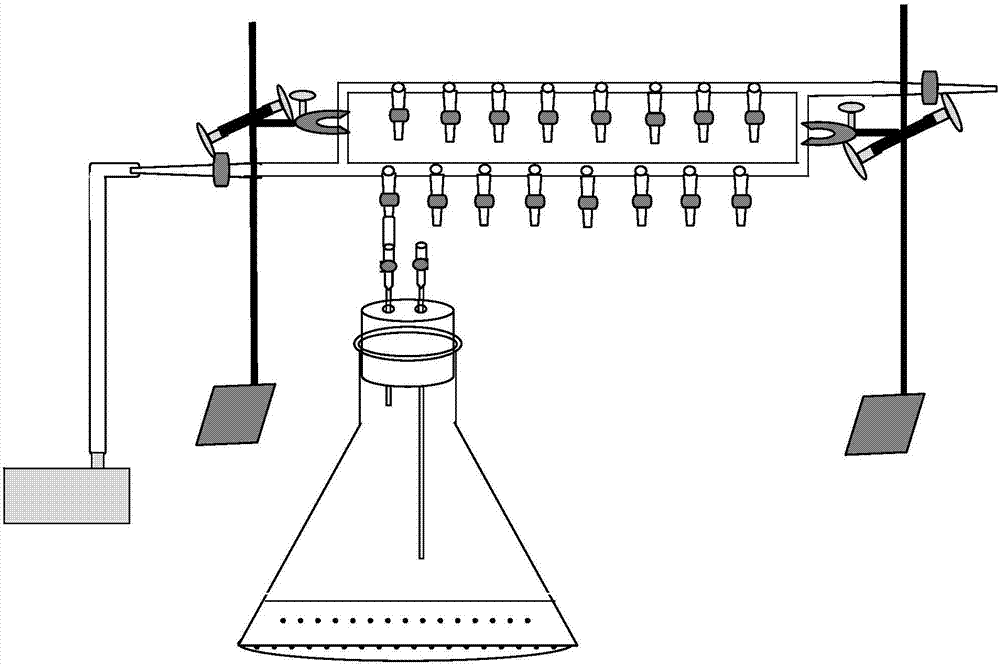

[0056] A method for measuring greenhouse gas emissions from indoor cultured soil, the method is carried out by using an integrated device for ventilation, cultivation and gas collection, and the integrated device for ventilation, cultivation and gas collection includes a ventilation device and a cultivation gas collection connected to the ventilation device device;

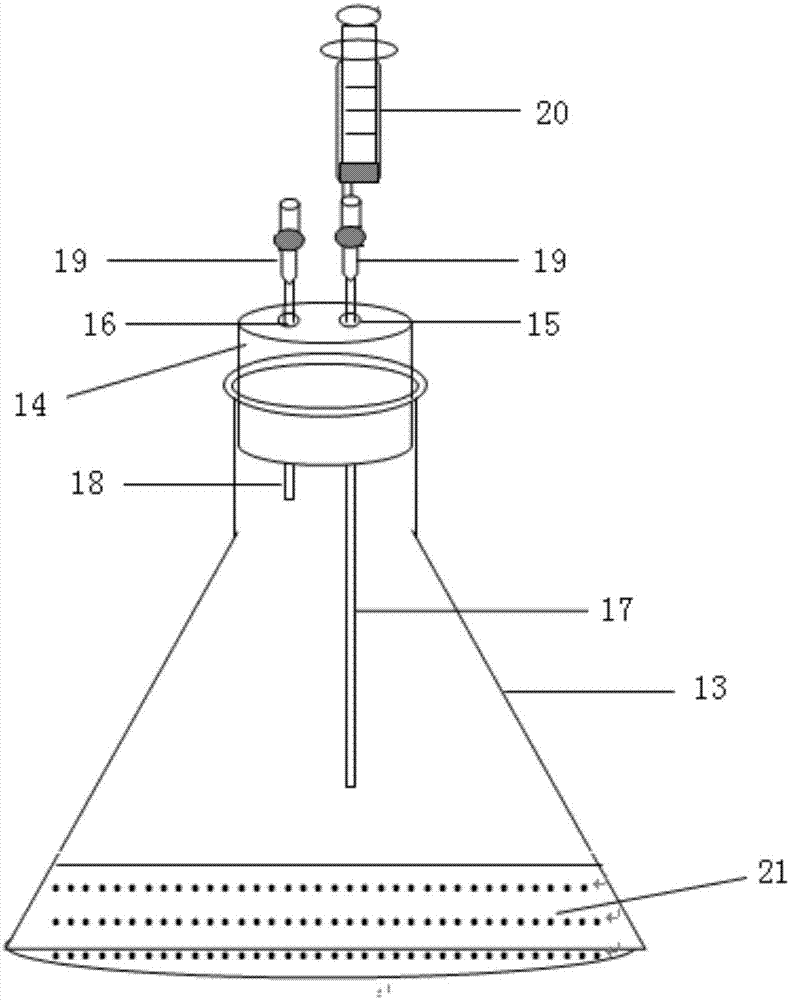

[0057] The cultured gas production device has a structure such as figure 2 As shown, the culture bottle 13 comprising the upper opening is provided with a sealing plug, the sealing plug is a silica gel plug 14, the diameter of the silica gel plug is consistent with the diameter of the bottle mouth, and the air inlet 15 and the gas extraction hole 16 are arranged on the sealing plug. Air inlet pipe 17 is fixed in the air inlet 15, and one end of air inlet pipe 17 is inserted in the culture bottle 13, and the distance between the air inlet pipe bottom and the cultivation soil surface layer is 1 / 8-1 / 5 of the height ...

Embodiment 2

[0074] A method for measuring indoor cultivation of soil greenhouse gas emissions, as described in Example 1, the difference is that the culture bottle is a 150ml triangular flask, the treated soil sample is 15g, the length of the air inlet pipe is 11cm, the balance pipe and the gas sampling needle pipe The volumes are 10ml and 20ml respectively. The ventilation time is 30s, and the gas is collected after 4 hours of airtight cultivation at a constant temperature of 25°C.

Embodiment 3

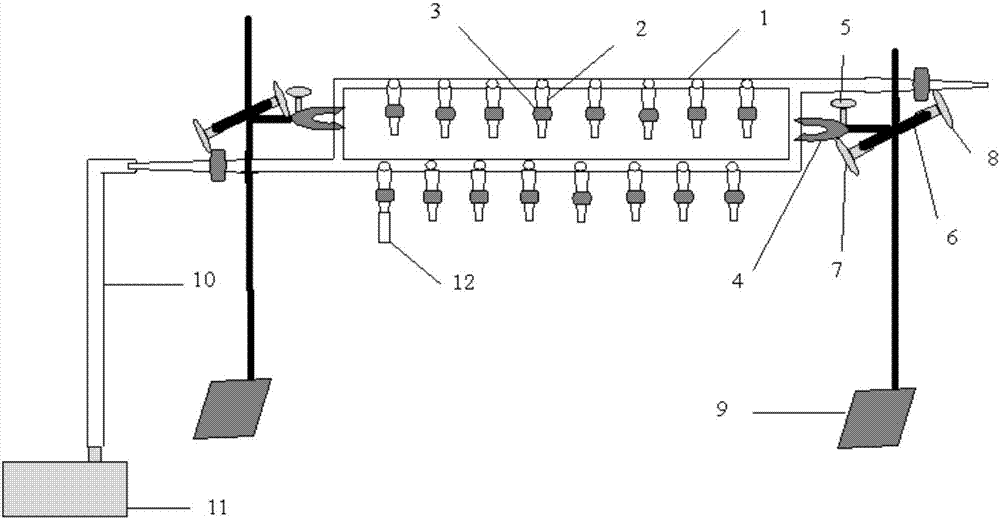

[0076] A method for measuring indoor cultivation soil greenhouse gas emissions, as described in Example 1, the difference is: the parallel straight pipes of the return-type pipe are equipped with 10 branch pipes at equal intervals, and the branch pipes on the two straight pipes cross Alternate, it is convenient to place the culture gas collection device, and can complete the gas exchange work of up to 20 culture bottles at the same time.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com