Remote real-time liquid pressure measurement system

A technology of real-time measurement and liquid pressure, which is applied in the direction of fluid pressure measurement using liquid as a pressure-sensitive medium. It can solve the problems of difficult replacement and maintenance, and easy damage of pressure components, so as to avoid difficult replacement and maintenance, avoid damage, and ensure safety. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

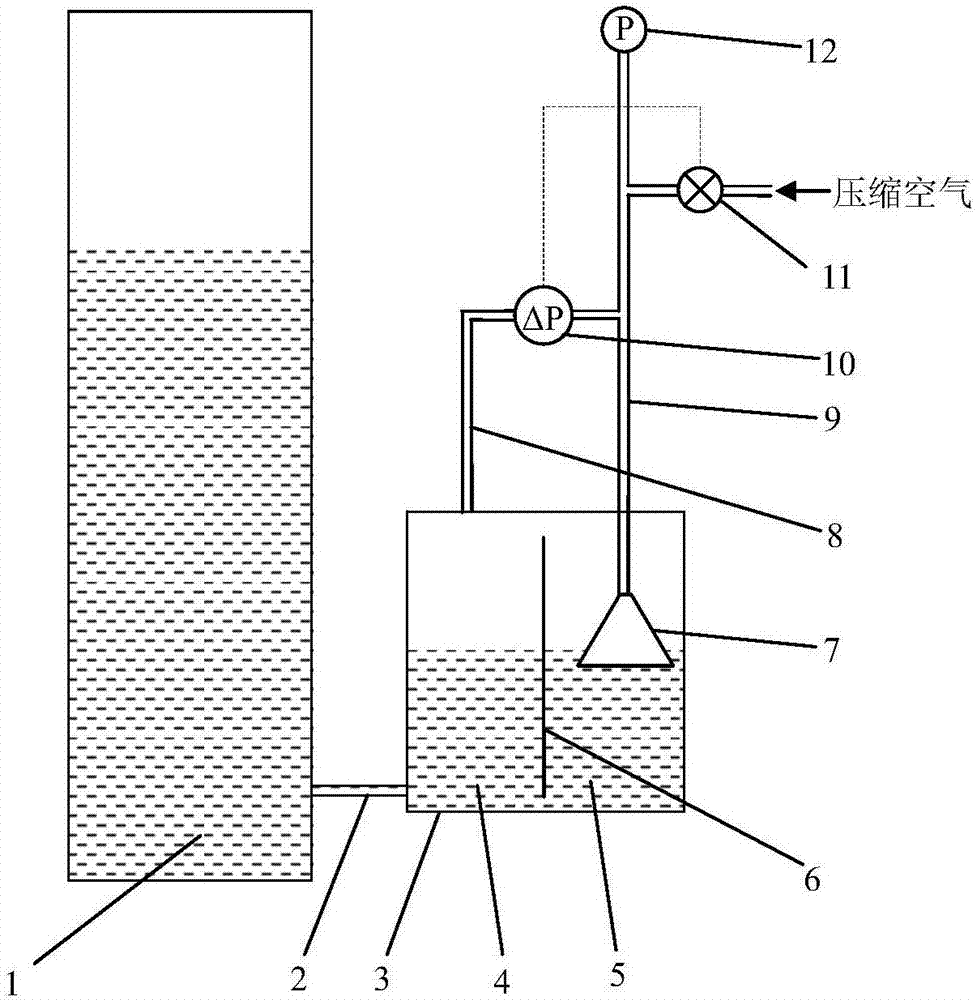

[0020] Evaporation and enrichment equipment is one of the commonly used equipment in the nuclear fuel reprocessing industry, and its common form is an evaporation kettle. During the evaporation process, it is necessary to monitor the liquid level in the kettle to control the heating power and determine the end point of evaporation. One of the most commonly used methods is to determine the liquid level by measuring the pressure of the liquid at the bottom of the tank. A remote pressure measurement system is installed at the bottom of the evaporator, and the liquid level can be monitored in real time through a simple conversion of the relationship between the pressure and the liquid level. The pressure measuring box is installed on the side of the kettle, and the comparison tube and measuring tube with a length of about 5 meters are remotely connected to the differential pressure sensor, solenoid valve, pressure measuring instrument and other components to realize remote measure...

Embodiment 2

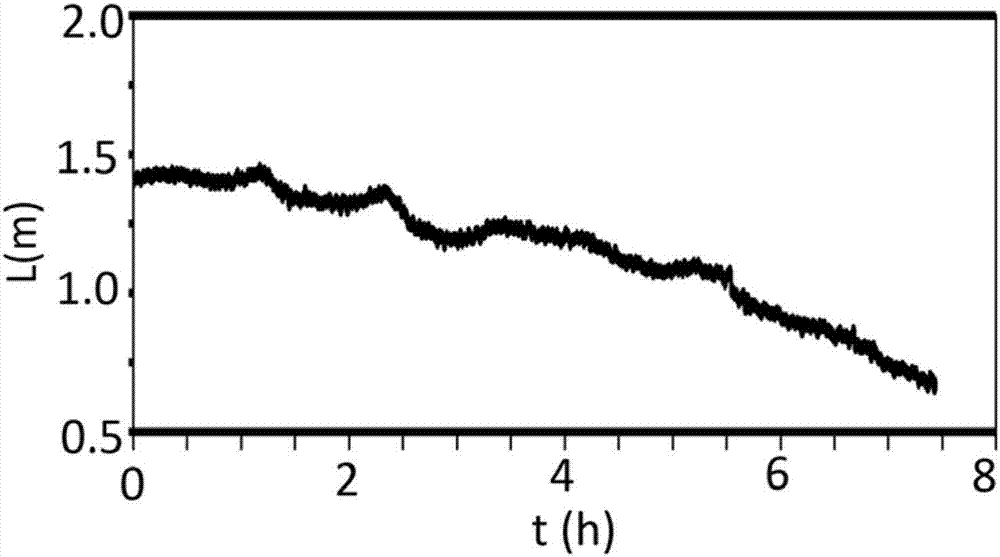

[0022] Pulse extraction column is one of the commonly used extraction equipment in nuclear chemical industry. Its column weight and pressure drop is one of the main parameters of its hydraulic performance. In nuclear chemical industry, it is often used to judge the operation of pulse column and determine whether it has liquid pan. A remote pressure measurement system is installed at the bottom of the pulse column, which can monitor the change of its column weight over time in real time. The pressure measurement box is installed on the bottom side of the pulse extraction column, and the remote measurement is realized by remotely connecting the differential pressure sensor, solenoid valve, pressure measuring instrument and other components through the comparison tube and the measuring tube with a length of about 20 meters. The pressure measuring instrument uses a pressure sensor connected to the computer to monitor the pressure drop of the column weight in real time on the compu...

Embodiment 3

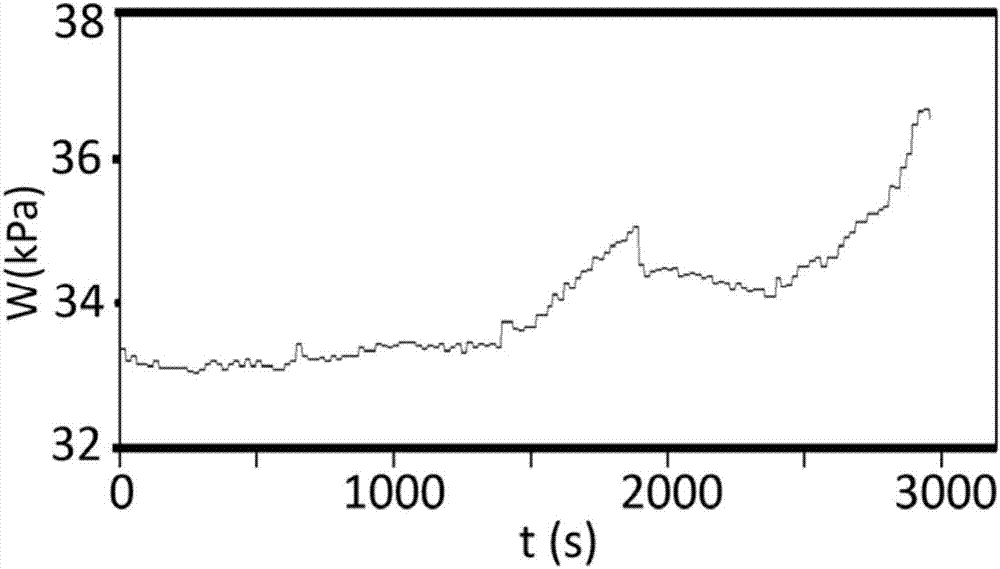

[0024] By installing remote pressure measurement systems on the upper and lower parts of the liquid-liquid two-phase interface of the pulse column, and measuring the pressure difference, the interface position can be calculated, thereby realizing real-time monitoring of the pulse column interface. The monitoring of the interface position is crucial to the operation control of the pulse column. It is used as an input signal to feed back to the discharge system, and the discharge system controls the interface to change within a reasonable range to ensure the normal operation of the pulse column. In actual implementation, two pressure measuring boxes are installed on the upper and lower parts of the liquid-liquid two-phase interface of the pulse column, with a height difference of 300 mm, and the respective differential pressure sensors and solenoid valves are remotely connected through a comparison tube and a measuring tube with a length of about 20 meters. and other components, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com