Intelligent air energy shrimp shell dryer

An air energy and dryer technology, applied in dryers, drying, drying of solid materials, etc., can solve the problems of low drying efficiency and difficult to control drying humidity, and achieve the effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

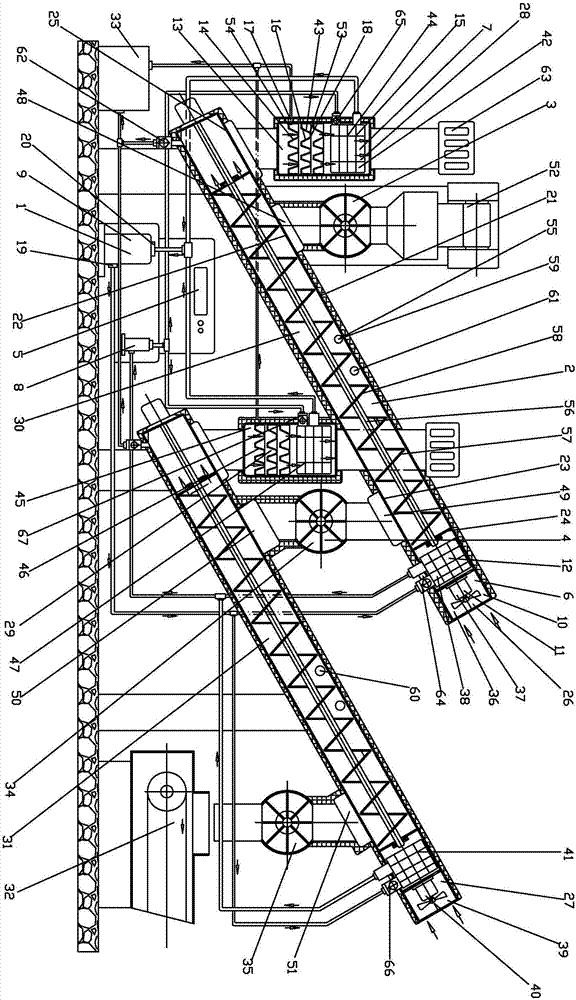

[0008] Below in conjunction with accompanying drawing, the present invention is further described:

[0009] Such as figure 1 The schematic diagram of the structure of the intelligent air energy shrimp shell dryer is shown. The intelligent air energy shrimp shell dryer includes a heat pump device 1, a screw conveyor 2, a rotary feed valve 3, a rotary discharge valve 4 and a controller 5; Heat pump device 1 includes hot air device 6, deodorizing device 7, expansion valve 8 and compressor 9; The deodorizing device 7 includes a deodorizing box 13, a dew condensation tank 14 and an evaporator 15, the dew condensation tank 14 and the evaporator 15 are located in the deodorizing box 13, and the dew condensation tank 14 is located below the evaporator 15; Groove 14 is made of the groove plate 16 of multi-layer aluminum alloy, and the groove top 53 and the groove bottom 54 of the groove plate 16 of the non-bottom layer and the groove top 53 of the groove plate 16 of the bottom layer a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com