Preparation method and application of rosemary hydrosol

A technology of rosemary hydrosol and rosemary, which is applied in the fields of pharmaceutical formulations, essential oils/fragrances, cosmetic preparations, etc. It can solve the problems of low sensory quality and unacceptable consumers, so as to improve applicability and sensory Quality, increase product value, effect of content improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The embodiment of the present invention provides a kind of preparation method of rosemary pure dew, comprises the following steps:

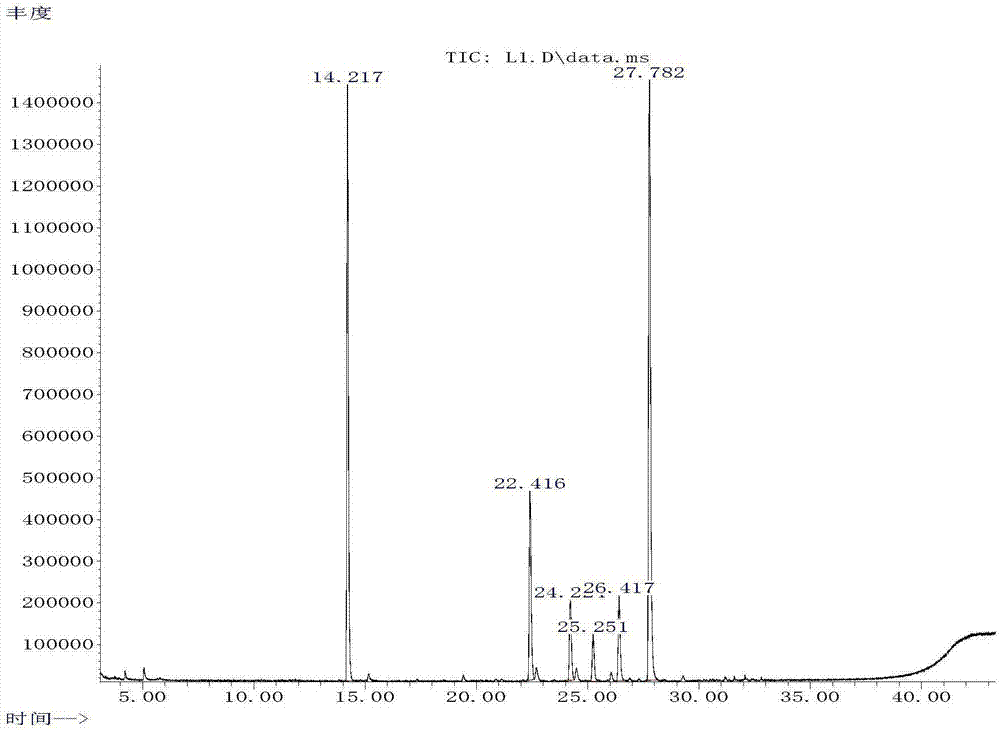

[0022] S01. Provide rosemary leaves, place them in steam distillation equipment for steam distillation, extract to obtain an oil-water blend, and obtain rosemary essential oil and rosemary crude hydrosol after oil-water separation;

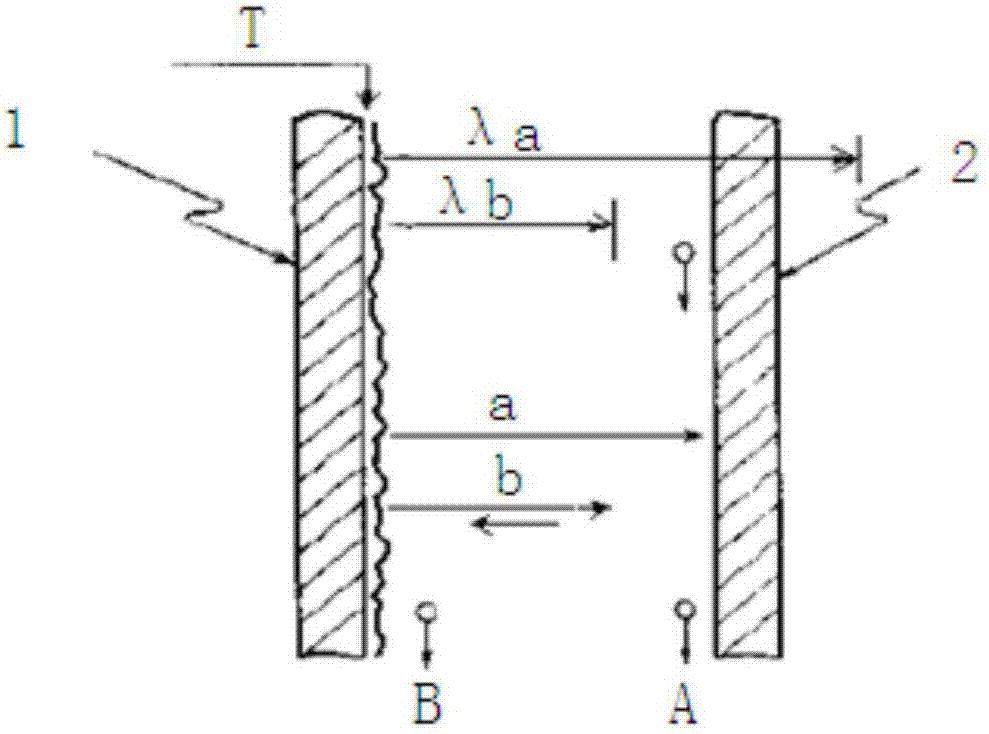

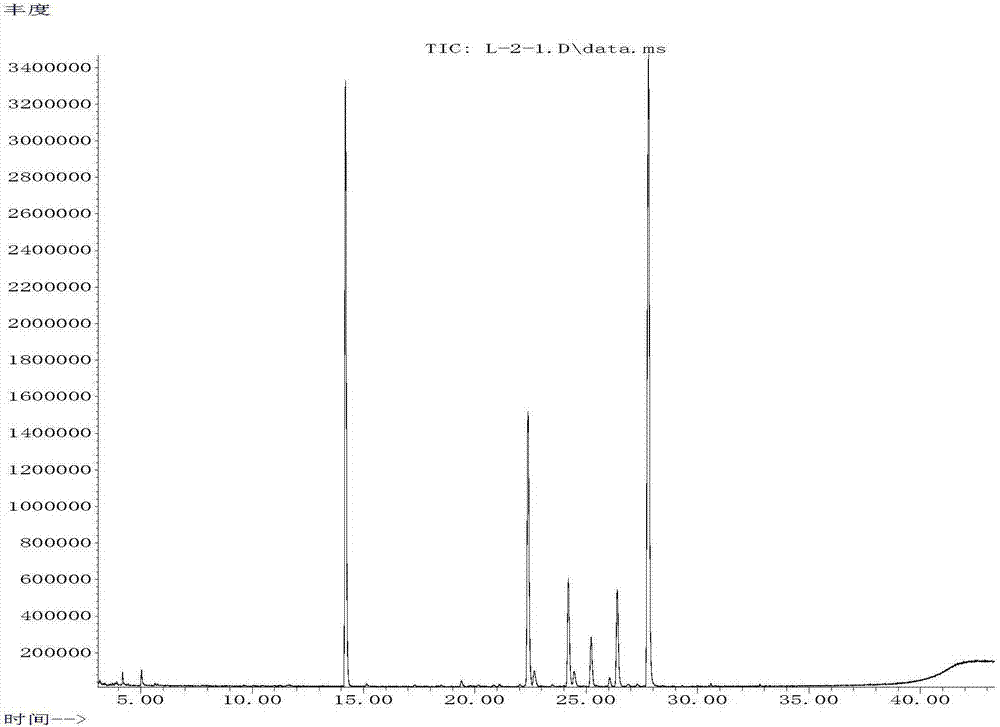

[0023] S02. Add the crude rosemary pure dew into molecular distillation equipment, adjust the distillation temperature of the molecular distillation equipment to 10-50°C, the condensation temperature to 0-5°C, and the pressure to 1000-3000Pa, and carry out molecular distillation separation Purify to obtain light components and heavy components, and collect the heavy components to obtain rosemary hydrosol.

[0024] Specifically, in the above step S01, the choice of raw material rosemary leaves is not strictly limited, and fresh rosemary leaves or dried rosemary leaves sold in the market or picked in the wild ca...

Embodiment 1

[0058] A preparation method of rosemary crude hydrosol, comprising the following steps: take 500g dried or fresh rosemary leaves, pulverize or cut into small pieces, add distilled water to submerge the material, soak at room temperature for 12 hours, and heat on a steam distillation device Until steam flows out, distill for 3 hours, collect condensed liquid, the upper layer is rosemary essential oil, obtains 10g, and the lower layer is rosemary pure dew, obtains 100g.

Embodiment 2

[0060] A method for preparing rosemary crude hydrosol, comprising the following steps: taking 500g dry or fresh rosemary leaves, pulverizing or cutting them into small pieces, placing them in steam distillation equipment, transporting steam through the material, condensing the steam again, and distilling 3 hours. Collect the condensate, the upper layer is rosemary essential oil, to obtain 10g, and the lower layer is rosemary crude hydrosol, to obtain 100g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com