High-temperature curing high-temperature-resistant impregnating adhesive and preparation method thereof

A high-temperature curing and high-temperature-resistant technology, applied in the direction of adhesives, epoxy resin glue, non-polymer adhesive additives, etc., can solve the problems of poor wetting effect of impregnating glue, decreased colloid performance, short service life, etc., to achieve strong colloid Performance, strong adhesion, and the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Preparation of component A: 100 parts by weight of bisphenol A epoxy resin, 0.5 part of silane coupling agent, and 1 part of thixotropic agent were mixed and stirred evenly.

[0025] Preparation of component B: 100 parts of liquid modified aromatic amine curing agent.

[0026] Mix and stir components A and B in a weight ratio of 4:1 to obtain a high-temperature curing high-temperature resistant impregnating glue.

Embodiment 2

[0028] Preparation of component A: 100 parts by weight of bisphenol A epoxy resin, 1 part of silane coupling agent, and 1 part of thixotropic agent were mixed and stirred evenly.

[0029] Preparation of component B: 100 parts of liquid modified aromatic amine curing agent.

[0030] Mix and stir components A and B in a weight ratio of 4:1 to obtain a high-temperature curing high-temperature resistant impregnating glue.

Embodiment 3

[0032] Preparation of component A: 100 parts by weight of bisphenol A epoxy resin, 2 parts of silane coupling agent, and 2 parts of thixotropic agent were mixed and stirred evenly.

[0033] Preparation of component B: 100 parts of liquid modified aromatic amine curing agent.

[0034] Mix and stir components A and B in a weight ratio of 4:1 to obtain a high-temperature curing high-temperature resistant impregnating glue.

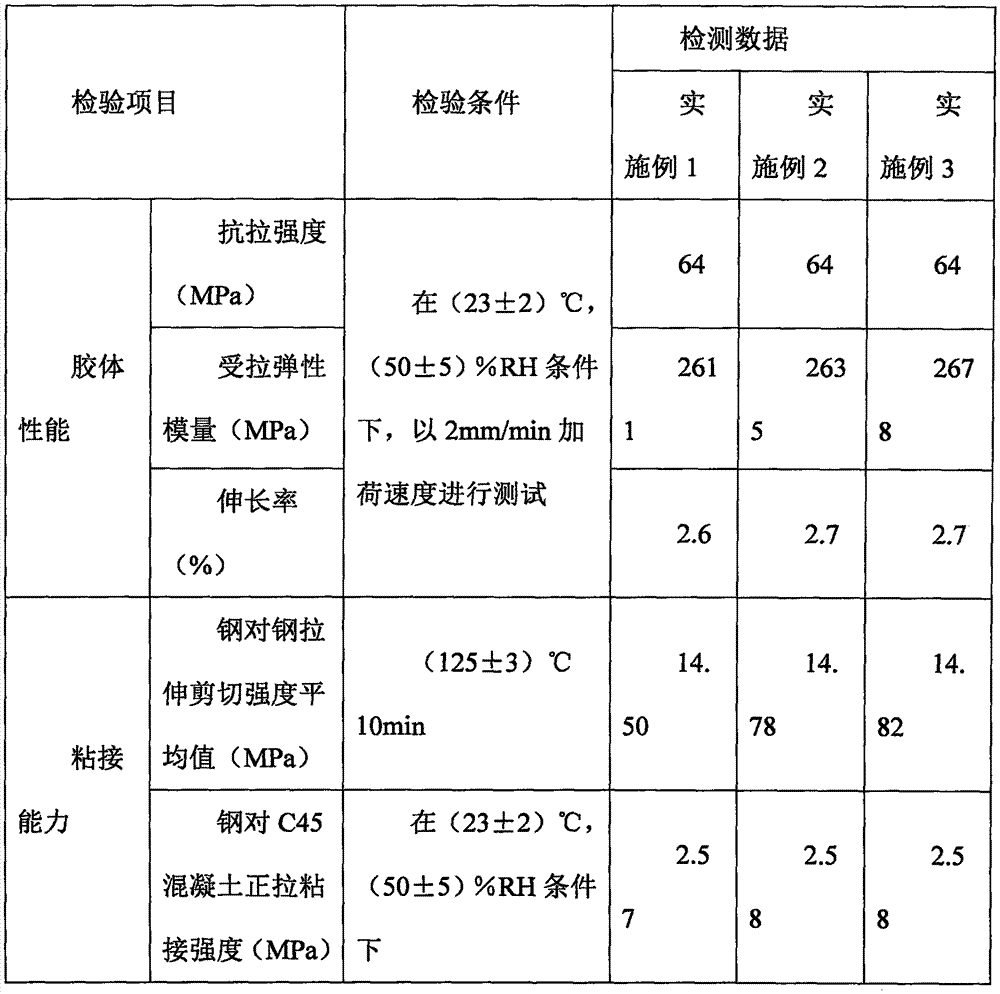

[0035] The dipping glue prepared in the three embodiments of the present invention is tested for performance according to the relevant requirements of GB 50728-2011, and the test data is shown in Attached Table 1

[0036] Table I

[0037]

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com