Silicone rubber composition and preparation method thereof

A technology of silicone rubber composition and methyl vinyl silicone raw rubber, which is applied in the field of silicone rubber composition and its preparation, can solve the problems of not being resistant to ozone, difficult to protect materials, low toughness, etc., and achieve good weather resistance, good The effect of the shielding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

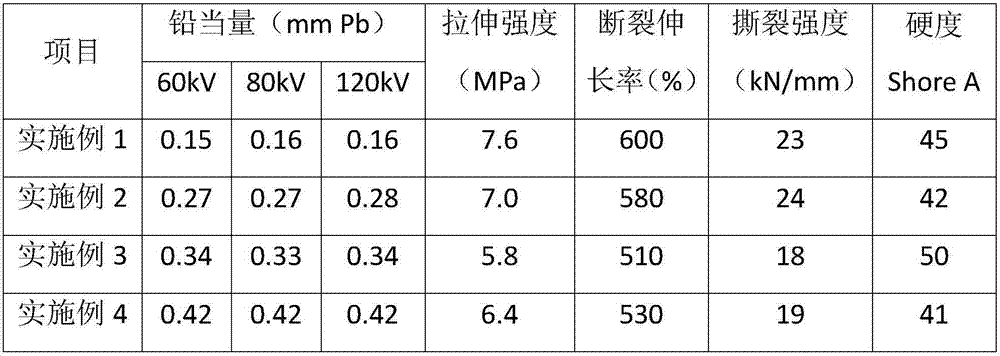

Embodiment 1

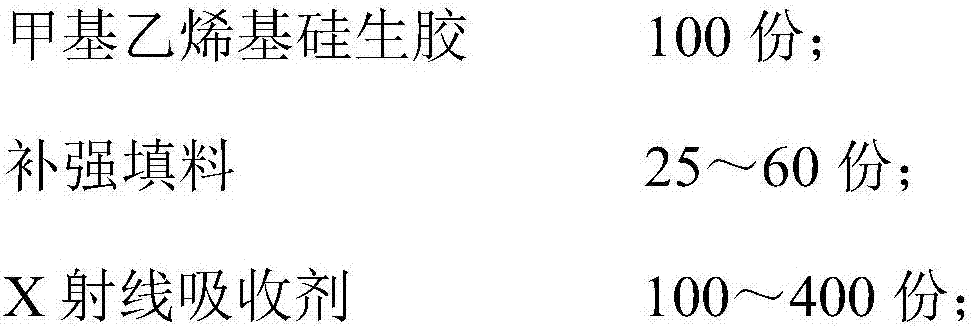

[0027] The silicone rubber composition of the present invention comprises the following components in parts by weight: 100 parts of methyl vinyl silicone raw rubber; 25-60 parts of reinforcing filler; 100-400 parts of X-ray absorber; 2-20 parts of treating agent; 0.2-3 parts of cross-linking agent. In this embodiment, the silicone rubber composition uses 100 parts of methyl vinyl silicone raw rubber, 60 parts of reinforcing filler, 100 parts of X-ray absorber, 2 parts of treating agent and 3 parts of crosslinking agent composition.

[0028] Wherein, the molecular weight of the methyl vinyl silicone raw rubber is 200,000-800,000, and the vinyl content is 0.03%-5%. The methyl vinyl silicone raw rubber is used as the matrix material of the silicone rubber composition. In this embodiment, the molecular weight of the methyl vinyl silicone raw rubber is 400,000, and the vinyl content is 1.5%.

[0029] The reinforcing filler is one or more of silicon micropowder, precipitated white...

Embodiment 2

[0035] This example is basically the same as Example 1, except that the silicone rubber composition uses 100 parts of methyl vinyl silicone raw rubber, 50 parts of reinforcing filler, 180 parts of X-ray absorber, 8 parts The treatment agent and 2.3 parts of cross-linking agent. Wherein, the molecular weight of the methyl vinyl silicone raw rubber is 200,000, and the vinyl content is 3%. The reinforcing filler is a composition composed of silicon micropowder, aluminum hydroxide, calcium carbonate and diatomaceous earth, and the X-ray absorber is a composition composed of zinc oxide, neodymium oxide, praseodymium oxide, and barium sulfate. The treating agent is realized by using dimethyldiethoxysilane, and the crosslinking agent is realized by using benzoyl peroxide and 2,4-dichlorobenzoyl peroxide.

[0036]When preparing the silicone rubber composition of the present invention, first knead at room temperature for 1.5 hours during the kneading process, then heat to 175° C. and ...

Embodiment 3

[0038] This example is basically the same as Example 1, except that the silicone rubber composition uses 100 parts of methyl vinyl silicone raw rubber, 40 parts of reinforcing filler, 260 parts of X-ray absorber, 12 parts The treatment agent and 1.5 parts of the cross-linking agent. Wherein, the molecular weight of the methyl vinyl silicone raw rubber is 500,000, and the vinyl content is 0.5%. The reinforcing filler is kaolin, the X-ray absorber is molybdenum disulfide, and the treatment agent is composed of hexamethyldisilazane, diphenylsilanediol and dimethyldimethoxysilane Composition, the crosslinking agent is a composition composed of tert-butyl peroxybenzoate, di-tert-butyl peroxide and dicumyl peroxide.

[0039] When preparing the silicone rubber composition of the present invention, knead at room temperature for 2 hours, then heat to 190° C. and knead for 1 hour during the kneading process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com