Preparation method of high antioxidant activity fish collagen polypeptide

A technology of oxidative activity and fish collagen, which is applied in the preparation methods of peptides, chemical instruments and methods, peptides, etc., can solve the problems that the products are difficult to meet the expectations of consumers, and the antioxidant activity of fish collagen is not available. Antioxidant activity, high safety, and the effect of improving the degree of absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

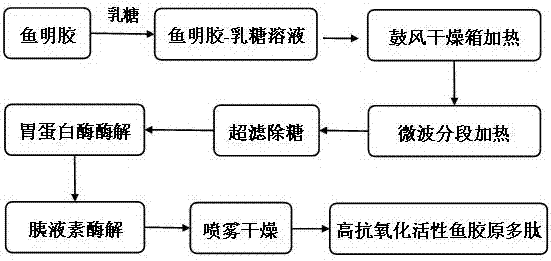

Image

Examples

Embodiment 1

[0027] 1. The first Maillard reaction between fish gelatin and lactose

[0028] (1) Preparation of fish gelatin solution: Dissolve fish gelatin in a 50°C water bath with 100 mM disodium hydrogen phosphate-sodium dihydrogen phosphate buffer (pH 7.4) to prepare a 150 mg / ml fish gelatin solution;

[0029] (2) Mixing fish gelatin and lactose: add lactose to the fish gelatin solution at a mass ratio of 1:1, and mix for 30 min.

[0030] (3) The first step of Maillard reaction: put the mixed fish gelatin and lactose solution in a blast drying oven, set the reaction temperature to 60°C, and the reaction time to 10 h.

[0031] 2. The second-step Maillard reaction between fish gelatin and lactose

[0032] The second Maillard reaction of fish gelatin and lactose is carried out in a microwave oven, which is divided into two stages. The first stage is to place the reacted fish gelatin-lactose mixture in the blast drying oven in the microwave oven, and set the reaction time to 4 min, the ...

Embodiment 2

[0042] 1. The first Maillard reaction between fish gelatin and lactose

[0043] (1) Preparation of fish gelatin solution: Dissolve fish gelatin in a 60°C water bath with 50 mM disodium hydrogen phosphate-sodium dihydrogen phosphate buffer (pH 7.4) to prepare a 150 mg / ml fish gelatin solution;

[0044] (2) Mixing fish gelatin and lactose: add lactose to the fish gelatin solution at a mass ratio of 1:2, and mix for 30 min.

[0045] (3) The first step of Maillard reaction: the mixed fish gelatin and lactose solution were placed in a blast drying oven, the reaction temperature was set at 50 °C, and the reaction time was 12 h.

[0046] 2. The second-step Maillard reaction between fish gelatin and lactose

[0047] The second Maillard reaction of fish gelatin and lactose is carried out in a microwave oven, which is divided into two stages. The first stage is to place the reacted fish gelatin-lactose mixture in the blast drying oven in the microwave oven, and set the reaction time to...

Embodiment 3

[0057] 1. The first Maillard reaction between fish gelatin and lactose

[0058] (1) Preparation of fish gelatin solution: Dissolve fish gelatin in a 55 °C water bath with 100 mM disodium hydrogen phosphate-sodium dihydrogen phosphate buffer (pH 8.0) to prepare a 160 mg / ml fish gelatin solution;

[0059] (2) Mixing of fish gelatin and lactose: add lactose to the fish gelatin solution at a mass ratio of 1:1, and mix for 20 min.

[0060] (3) The first step of Maillard reaction: the mixed fish gelatin and lactose solution were placed in a blast drying oven, the reaction temperature was set at 70 °C, and the reaction time was 6 h.

[0061] 2. The second-step Maillard reaction between fish gelatin and lactose

[0062] The second Maillard reaction of fish gelatin and lactose is carried out in a microwave oven, which is divided into two stages. The first stage is to place the reacted fish gelatin-lactose mixture in the blast drying oven in the microwave oven, and set the reaction time ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com