A preparation device and method for a large-scale fine-grained homogeneous aluminum alloy ingot

An aluminum alloy ingot and preparation device technology, applied in the field of metal material processing, can solve the problems of coarse and uneven structure, easy cracking, composition segregation, etc., and achieve precise design and control, clean design and control, and high energy density. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

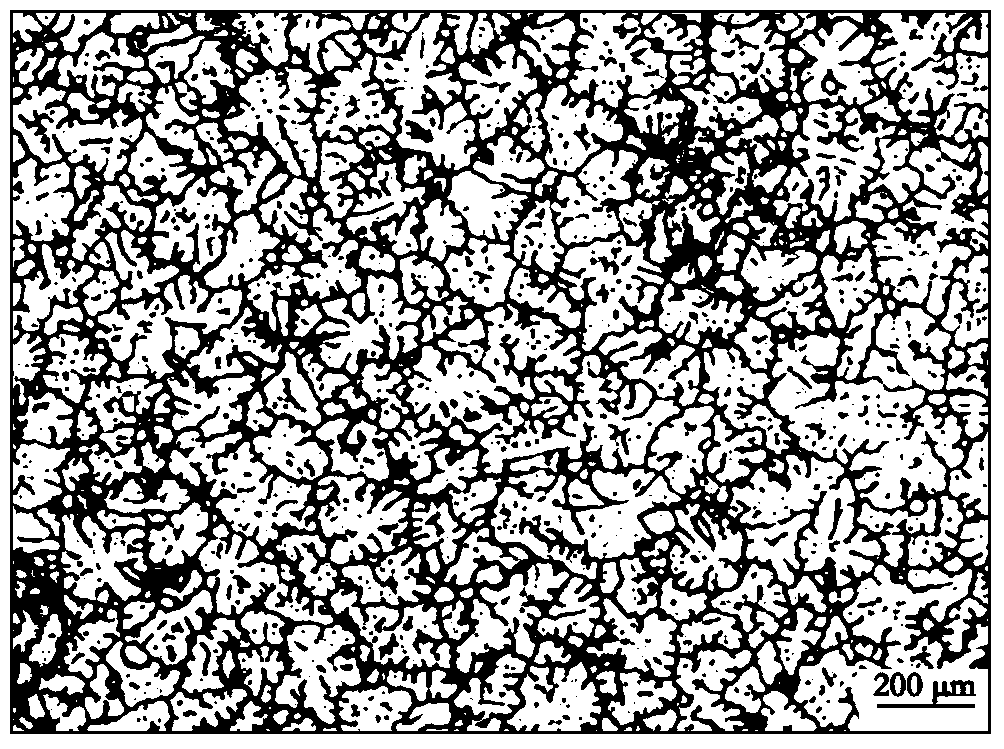

[0054] An aluminum processing enterprise prepares Φ582mm 7055 aluminum alloy ingots. It has strict requirements on the uniformity of the internal structure of the ingot. The average grain size of the cross-section should be less than 180 μm, and the grain size deviation should be controlled within 8%. The segregation rate of alloy elements Control within 6%.

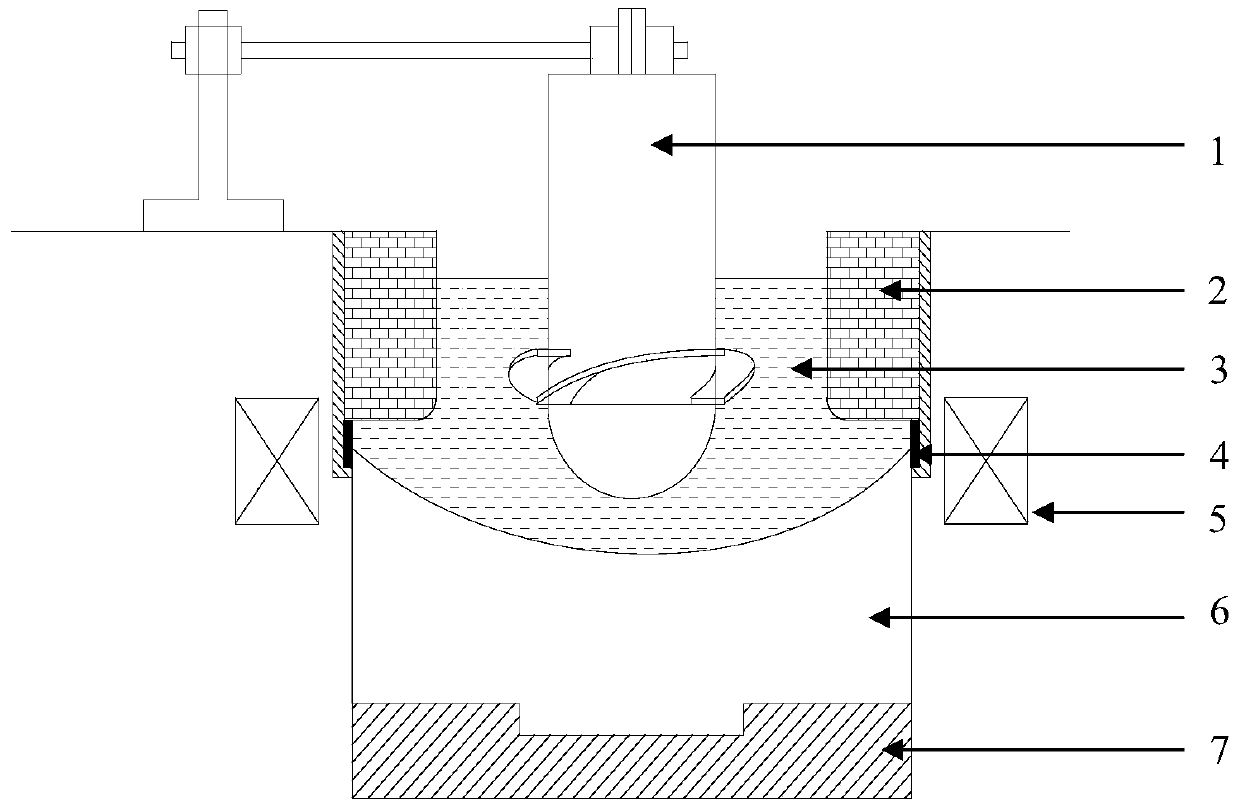

[0055] Adopt the present invention to produce the 7055 aluminum alloy round ingot that diameter is 582mm, the schematic diagram of device structure is as follows figure 1 shown. The cooler 1 is arranged on the casting platform, the outer diameter of the cooler 1 is 300mm, the cooler 1, the hot top 2 and the crystallizer 4 are concentric, and the bottom of the cooler 1 is flush with the bottom of the crystallizer 4. The electromagnetic stirrer 5 is arranged on the outer periphery of the crystallizer 4, and the electromagnetic stirring method adopts rotating electromagnetic stirring.

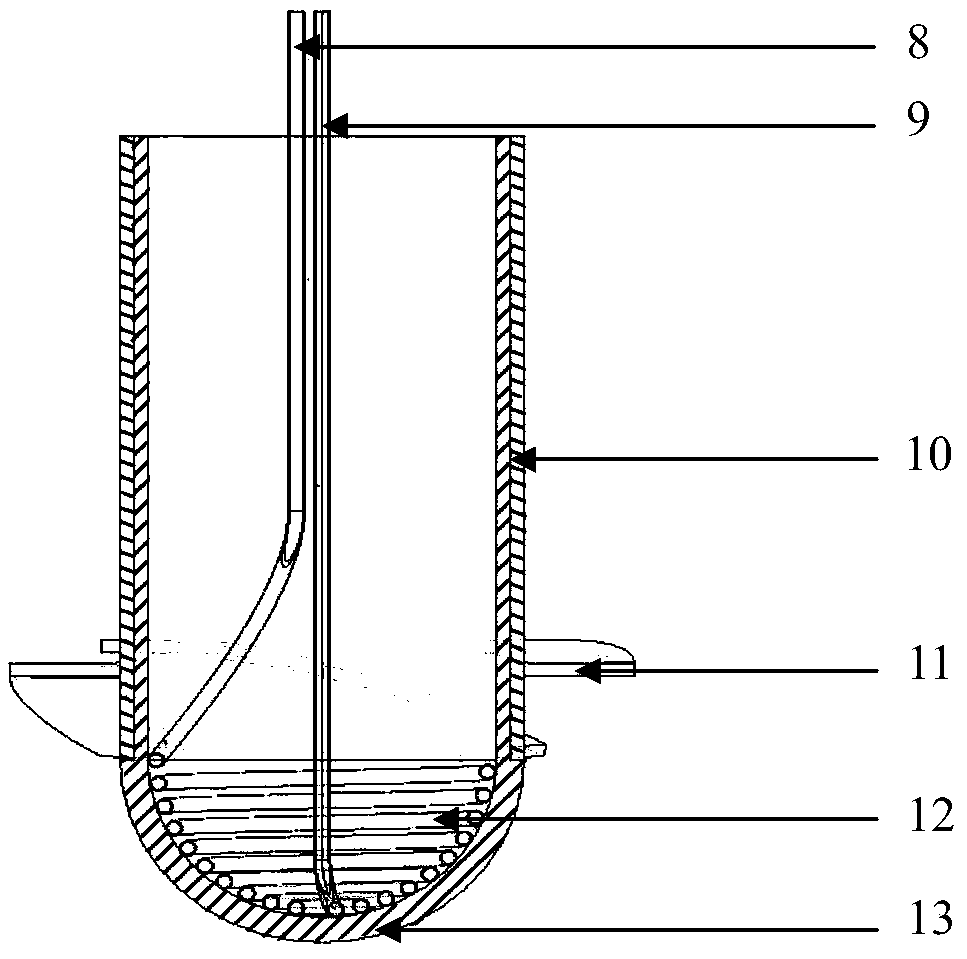

[0056] The inner tube of the cooler...

Embodiment 2

[0064] An aluminum processing enterprise prepares a 7050 aluminum alloy flat ingot with a specification of 520mm×1560mm. It has strict requirements on the uniformity of the internal structure of the ingot. The average grain size should be less than 156μm, and the grain size deviation should be controlled within 6%. The maximum segregation rate is controlled within 6%, and there are no wrinkles on the surface and no cracks inside.

[0065] Adopt the present invention to produce the 7050 aluminum alloy flat ingot of 520mm * 1560mm, the schematic diagram of device structure is as follows figure 1 shown. Cooler 1 has a diameter of 200mm and is installed on the casting platform. Three coolers are arranged in a row and evenly arranged, inserted into the crystallizer with a center distance of 440mm. The bottom of cooler 1 is flush with the bottom of crystallizer 4 . The electromagnetic stirrer 5 is arranged on the outer periphery of the crystallizer 4, and the electromagnetic stirri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com