Aluminum powder production device

A production device and technology of aluminum powder, applied in grain processing and other directions, can solve the problems of large floor space, high cost, lack of intensive equipment, etc., and achieve the effect of reducing floor space and labor, and achieving a high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

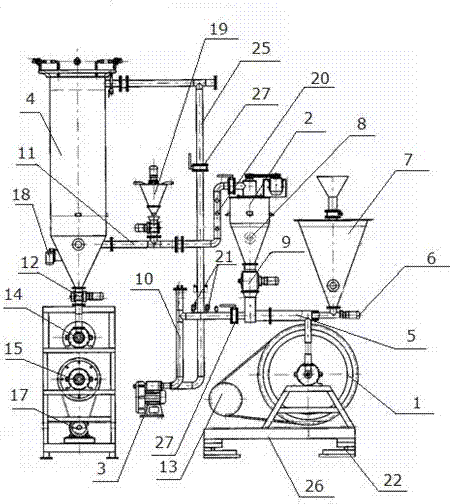

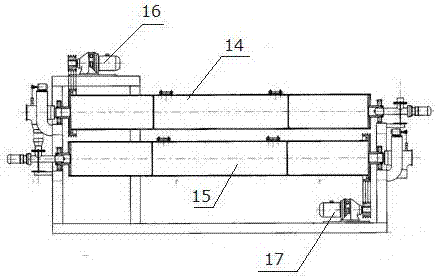

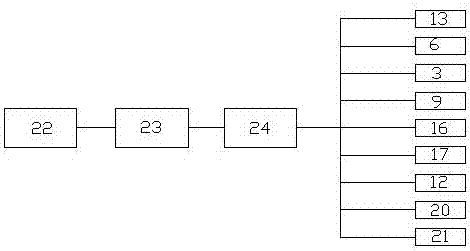

[0023] An aluminum powder production device, comprising a ball mill 1, the ball mill 1 is connected with a ball mill motor 13, and also includes a cyclone separator 2, a blower fan 3, a dust remover 4, a polishing machine, the dust remover 4 is a pulse dust remover, and the pulse dust remover A vibrator 18 is provided on the side wall of the ball mill. The feed port of the ball mill 1 is connected to the feed pipe 5, and the feed pipe 5 is connected to the raw material tank 7 through the conveying device 6. The conveying device 6 is a Jiaolong conveying device , the discharge port of the ball mill 1 is connected with the cyclone separator 2 through the discharge pipe 8, and the bottom of the cyclone separator 2 is provided with a valve 9 and is connected with the air outlet pipe 10 and the feed pipe 5 of the blower fan 3 respectively, The air outlet pipe 10 is communicated with the feed pipe 5, the top of the cyclone separator 2 is connected with the dust remover 4 through the ...

Embodiment 2

[0025] An aluminum powder production device, comprising a ball mill 1, the ball mill 1 is connected with a ball mill motor 13, and also includes a cyclone separator 2, a blower fan 3, a dust remover 4, a polishing machine, the dust remover 4 is a pulse dust remover, and the pulse dust remover A vibrator 18 is provided on the side wall of the ball mill. The feed port of the ball mill 1 is connected to the feed pipe 5, and the feed pipe 5 is connected to the raw material tank 7 through the conveying device 6. The conveying device 6 is a Jiaolong conveying device , the discharge port of the ball mill 1 is connected with the cyclone separator 2 through the discharge pipe 8, and the bottom of the cyclone separator 2 is provided with a valve 9 and is connected with the air outlet pipe 10 and the feed pipe 5 of the blower fan 3 respectively, The air outlet pipe 10 is provided with an air outlet solenoid valve 21, and communicates with the feed pipe 5, and the top of the cyclone separa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com