Method for preparing catalyst applied to preparation of ethylene by hydrogenation of acetylene through super-gravity process and application of catalyst

A technology of acetylene hydrogenation and high gravity method, which is applied in the direction of molecular sieve catalysts, chemical instruments and methods, catalyst activation/preparation, etc. It can solve the problems of unreported catalysts, high catalyst costs, and low preparation costs, so as to avoid hydrogen reduction Effects of operation, stability enhancement, and activity enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

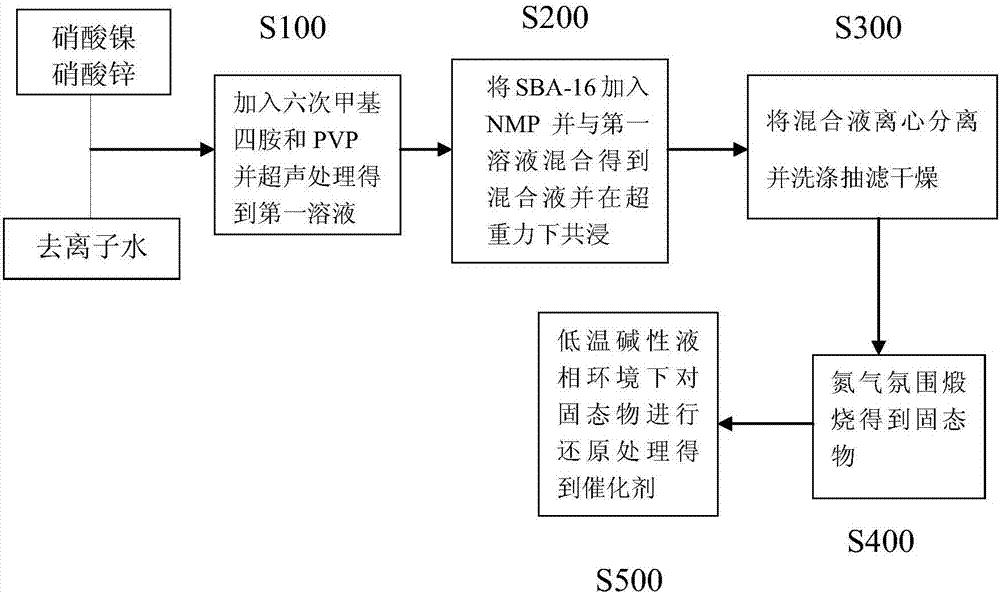

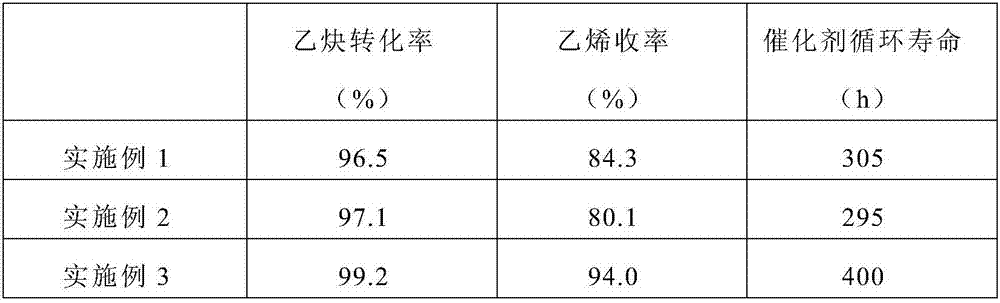

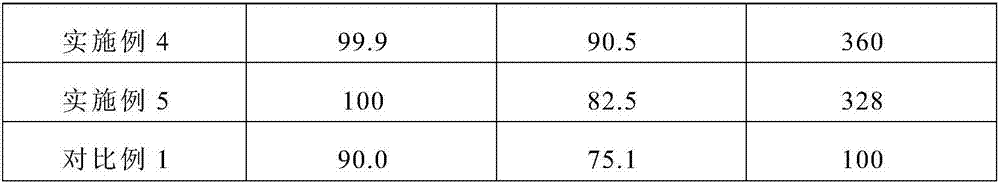

[0056] refer to figure 1, in step S100, weigh 7.2g of nickel nitrate and 25g of zinc nitrate and dissolve them in 30g of deionized water, then add 2g of hexamethylenetetramine and 1.5g of PVP and ultrasonicate at 60°C for 10 minutes, and the ultrasonic power is set to 360W, forming the first solution. Then in step S200, weigh 100g of SBA-16 and add it to 65g of NMP, and mix it with the above-mentioned first solution to form a mixed solution, and transfer it to the high-gravity rotating packed bed for co-impregnation, wherein the rotating speed of the high-gravity rotating packed bed The setting is 1500r / min, the supergravity level is controlled at 100G, and the time is maintained for 50min. Then in step S300, the mixed solution treated in step S200 is centrifuged, and the solid matter is washed with absolute ethanol for 2 to 3 times and then dried by suction. The drying process is maintained at 120° C. for 10 hours. Then in step S400 , calcined in a nitrogen atmosphere at a ...

Embodiment 2

[0059] refer to figure 1 , in step S100, weigh 7.2g of nickel nitrate and 25g of zinc nitrate and dissolve them in 30g of deionized water, then add 2g of hexamethylenetetramine and 1.5g of PVP and ultrasonicate at 60°C for 10 minutes, and the ultrasonic power is set to 360W, forming the first solution. Then in step S200, weigh 100g of SBA-16 and add it to 65g of NMP, and mix it with the above-mentioned first solution to form a mixed solution, and transfer it to the high-gravity rotating packed bed for co-impregnation, wherein the rotating speed of the high-gravity rotating packed bed The setting is 1700r / min, the supergravity level is controlled at 120G, and the time is maintained for 50min. Then in step S300, the mixed solution treated in step S200 is centrifuged, and the solid matter is washed with absolute ethanol for 2 to 3 times and then dried by suction. The drying process is maintained at 100° C. for 10 hours. Then in step S400 , calcined in a nitrogen atmosphere at a...

Embodiment 3

[0062] refer to figure 1 , in step S100, weigh 7.2g of nickel nitrate and 25g of zinc nitrate and dissolve them in 30g of deionized water, then add 2g of hexamethylenetetramine and 1.5g of PVP and ultrasonicate at 60°C for 10 minutes, and the ultrasonic power is set to 360W, forming the first solution. Then in step S200, weigh 100g of SBA-16 and add it to 65g of NMP, and mix it with the above-mentioned first solution to form a mixed solution, and transfer it to the high-gravity rotating packed bed for co-impregnation, wherein the rotating speed of the high-gravity rotating packed bed The setting is 2000r / min, the supergravity level is controlled at 150G, and the time is maintained for 40min. Then in step S300, the mixed solution treated in step S200 is centrifuged, and the solid matter is washed with absolute ethanol for 2 to 3 times and then dried by suction. The drying process is maintained at 150° C. for 10 hours. Then in step S400 , calcined in a nitrogen atmosphere at a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com