Treatment methods for mineral medicine or shellfish traditional Chinese medicine

A treatment method and shellfish technology, which is applied in the field of mineral medicine or shellfish Chinese medicine treatment, can solve the problems of increasing storage difficulty, endangering human health, affecting human absorption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

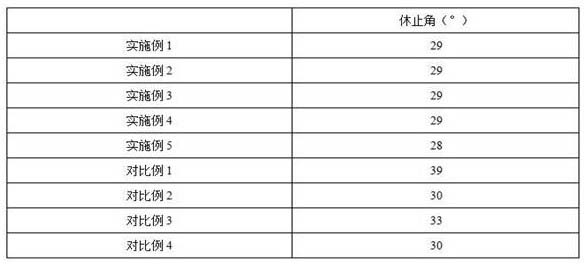

Examples

Embodiment 1

[0027] The processing method for mineral medicine or shellfish traditional Chinese medicine, including steps:

[0028] (1) Crushing oysters to obtain coarse powder;

[0029] (2) Pour the coarse powder into 5 times the weight of ethanol-water mixed solution and soak for 12 hours, filter to obtain the first filter residue;

[0030] (3) Microwave the first filter residue at 300W for 3 minutes, then add it to 5 times the weight of ethyl acetate, ultrasonically treat it at 25 kHz for 2 hours, and filter to obtain the second filter residue, which is spray-dried to obtain a powder;

[0031] (4) Add the powder to 2 times the weight of water, stir to form a suspension, pre-cool to 0°C, then freeze at -70°C for 12 hours, and then vacuum-dry at 0.09MPa for 3 hours to obtain a dry powder;

[0032] (5) Ultrafine pulverization of the dry powder to obtain a fine powder with a particle size of 1 μm;

[0033] (6) Dissolve hydroxypropyl-β-cyclodextrin in 8 times the weight of water, then add ...

Embodiment 2

[0038] The processing method for mineral medicine or shellfish traditional Chinese medicine, including steps:

[0039] (1) Crushing oysters to obtain coarse powder;

[0040] (2) Pour the coarse powder into 10 times the weight of ethanol-water mixed solution and soak for 24 hours, filter to obtain the first filter residue;

[0041] (3) Microwave the first filter residue at 450W for 5 minutes, then add it to 8 times the weight of ethyl acetate, 40kHz ultrasonic treatment for 3 hours, and filter to obtain the second filter residue, which is spray-dried to obtain a powder;

[0042] (4) Add the powder to 3 times the weight of water, stir to form a suspension, pre-cool to 5°C, then freeze at -70°C for 24 hours, and then vacuum-dry at 0.096MPa for 4 hours to obtain a dry powder;

[0043] (5) Ultrafine pulverization of the dry powder to obtain a fine powder with a particle size of 10 μm;

[0044] (6) Dissolve hydroxypropyl-β-cyclodextrin in 10 times the weight of water, then add the...

Embodiment 3

[0049] The processing method for mineral medicine or shellfish traditional Chinese medicine, including steps:

[0050] (1) Crushing oysters to obtain coarse powder;

[0051] (2) Pour the coarse powder into 5 times the weight of ethanol-water mixed solution and soak for 24 hours, filter to obtain the first filter residue;

[0052] (3) Microwave the first filter residue at 300W for 5 minutes, then add it to 5 times the weight of ethyl acetate, 40kHz ultrasonic treatment for 2 hours, filter to obtain the second filter residue, spray dry to obtain powder;

[0053] (4) Add the powder to 3 times the weight of water, stir to form a suspension, pre-cool to 0°C, then freeze at -70°C for 24 hours, and then vacuum-dry at 0.09MPa for 4 hours to obtain a dry powder;

[0054] (5) Ultrafine pulverization of the dry powder to obtain a fine powder with a particle size of 1 μm;

[0055] (6) Dissolve hydroxypropyl-β-cyclodextrin in 10 times the weight of water, then add the fine powder obtaine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com