Biomass aqueous conductive binding system and chemical power supply employing same

A technology based on biomass and water system, which is applied in the field of water system conductive bonding system and chemical power supply. It can solve the problems of long mixing time of electrode slurry, pollution of environment by organic solvent NMP, high cost of binder PVdF, etc., to reduce stirring time, Good wettability, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Li-ion battery system. The preparation method of the biomass water-based conductive bonding system and the lithium-ion battery cathode sheet using the system is completed according to the following steps:

[0034] 1. At 10-80 degrees Celsius, add 5% oxalic acid into the monomer in the liquid phase, and wait until the catalyst is completely dissolved.

[0035] 2. In the above mixed solution, add lithium iron phosphate cathode material, the mass ratio of monomer to active material is 20:100, and mix and stir for 5 minutes with a high-speed homogenizer to obtain a uniform electrode paste.

[0036] 3. The obtained electrode paste is coated or sprayed on the electrode current collector, and after a heating and curing procedure, the heating temperature is 80-140 degrees Celsius, and the curing time is 30 minutes. The preparation of the lithium-ion battery electrode sheet is completed.

[0037] In this implementation, the content of the generated polymer binder in the pole pi...

Embodiment 2

[0046] Li-ion battery system. The preparation method of the biomass water-based conductive bonding system and the lithium-ion battery cathode sheet using the system is completed according to the following steps:

[0047] 1. At 10-80 degrees Celsius, preferably 40 degrees Celsius, add 10% by mass of oxalic acid into the monomer in the liquid phase, and wait until the catalyst is completely dissolved.

[0048] 2. In the above mixed solution, add lithium iron phosphate positive electrode material, the mass ratio of its monomer to active material is 20:100, and mix and stir for 5 minutes through a high-speed homogenizer to obtain a uniform electrode paste.

[0049] 3. The obtained electrode paste is coated or sprayed on the electrode current collector, and after a heating and curing procedure, the heating temperature is 120 degrees Celsius, and the curing time is 30 minutes. The preparation of the lithium-ion battery electrode sheet is completed.

[0050] Compared with Example 1,...

Embodiment 3

[0056] Li-ion battery system. The preparation method of the biomass water-based conductive bonding system and the lithium-ion battery cathode sheet using the system is completed according to the following steps:

[0057] 1. At 20 degrees Celsius, add 30% mass fraction of formic acid into the monomer in the liquid phase, and mix well.

[0058] 2. In the above mixed solution, add the electrode lithium cobaltate positive electrode material, the mass ratio of its monomer to active material is 10:100, mix and stir for 10 minutes to obtain a uniform electrode paste.

[0059] 3. The obtained electrode paste is coated or sprayed on the electrode current collector, and after a heating and curing procedure, the heating temperature is 120 degrees Celsius, and the curing time is 60 minutes. The preparation of the lithium-ion battery electrode sheet is completed.

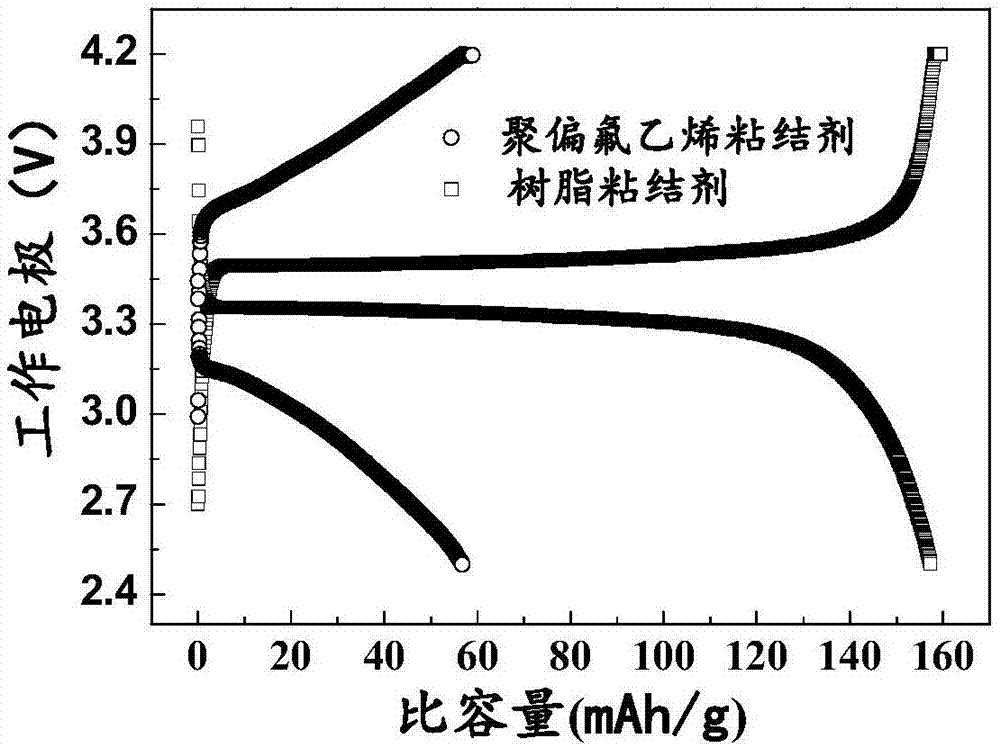

[0060] Using lithium cobalt oxide as the active material, the specific capacity of the electrode 5C rate is higher than 100mA...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com