Preparation method of chitosan / molybdenum disulfide photocatalytic anti-microbial coating

A molybdenum disulfide and antibacterial coating technology, applied in coating, electrolytic coating, electrophoretic plating, etc., can solve the problems of difficult control of product size and morphology, high reaction temperature of products or reactants, pollution of sulfur-containing gas, etc. , to achieve good pH stability, the preparation method is simple and feasible, and the effect of improving biological activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

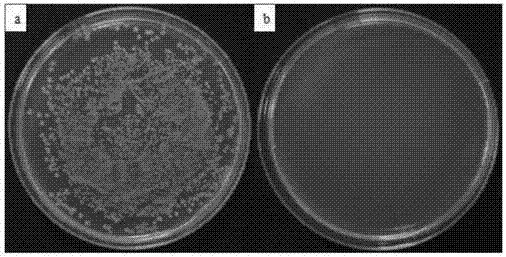

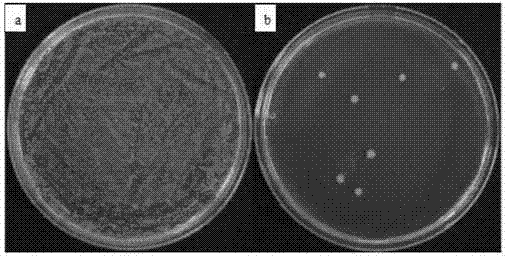

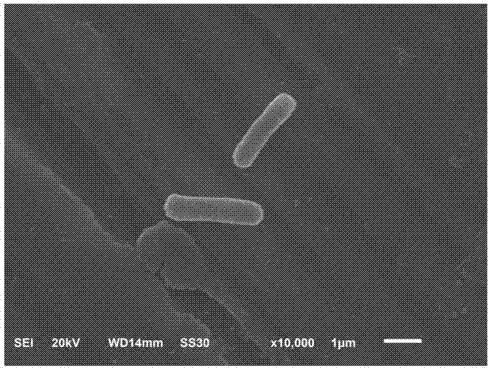

Embodiment 1

[0032] Put 250mg molybdenum disulfide and 200mg chitosan into the mortar and grind for 30min, add 0.5ml of 1-butyl-3-methylimidazolium hexafluorophosphate (ion-assisted grinding solution) into the mortar, and then keep grinding After 120 min, the grinding product was collected, and the product was washed by centrifugation at 9000 rpm with acetone, DMF and 1% acetic acid in sequence, each washing three times, to remove the ionic solution and excess chitosan. Finally, the precipitate was dispersed in deionized water and centrifuged at 1800 rpm for 20 min to remove unexfoliated MoS 2 , the chitosan / molybdenum disulfide nano-dispersion system obtained at this time was diluted to 100ml with deionized water to obtain a chitosan / molybdenum disulfide nano-dispersion system solution and stored at 4°C for use.

[0033] Grind the titanium alloy disc (diameter 6mm, thickness 2.5mm) with sandpaper step by step until 800#, and then ultrasonically clean it in ethanol and deionized water. Et...

Embodiment 2

[0036]Put 250mg molybdenum disulfide and 100mg chitosan into the mortar and grind for 15min, add 0.5ml of 1-butyl-3-methylimidazolium hexafluorophosphate (ion-assisted grinding solution) into the mortar, and then keep grinding After 90 min, the grinding product was collected, and the product was washed by centrifugation at 9000 rpm with acetone, DMF and 0.5% acetic acid in sequence, each washing three times, to remove the ionic solution and excess chitosan. Finally, the precipitate was dispersed in deionized water and centrifuged at 1500 rpm for 20 min to remove unexfoliated MoS 2 , the chitosan / molybdenum disulfide nano-dispersion system obtained at this time was diluted to 100ml with deionized water to obtain a chitosan / molybdenum disulfide nano-dispersion system solution and stored at 4°C for use.

[0037] Grind the titanium alloy disc (diameter 6mm, thickness 2.5mm) with sandpaper step by step until 800#, then ultrasonically clean it in ethanol and deionized water in turn,...

Embodiment 3

[0040] Put 150mg molybdenum disulfide and 200mg chitosan into the mortar and grind for 30min, add 0.5ml of 1-butyl-3-methylimidazolium hexafluorophosphate (ion-assisted grinding solution) into the mortar, and then keep grinding After 120 min, the grinding product was collected, and the product was washed by centrifugation at 9000 rpm with acetone, DMF and 1% acetic acid in sequence, each washing three times, to remove the ionic solution and excess chitosan. Finally, the precipitate was dispersed in deionized water and centrifuged at 1800 rpm for 20 min to remove unexfoliated MoS 2 , the chitosan / molybdenum disulfide nano-dispersion system obtained at this time was diluted to 100ml with deionized water to obtain a chitosan / molybdenum disulfide nano-dispersion system solution and stored at 4°C for use.

[0041] Grind the titanium alloy disc (diameter 6mm, thickness 2.5mm) with sandpaper step by step until 800#, and then ultrasonically clean it in ethanol and deionized water. De...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com