High-performance edible fungus slag activated carbon and preparation method thereof

An edible fungus, high-performance technology, applied in chemical instruments and methods, other chemical processes, inorganic chemistry, etc., can solve the problems of insufficient adsorption effect, less research, unsatisfactory adsorption capacity of activated carbon, etc., and achieve excellent adsorption effect, preparation The effect of simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

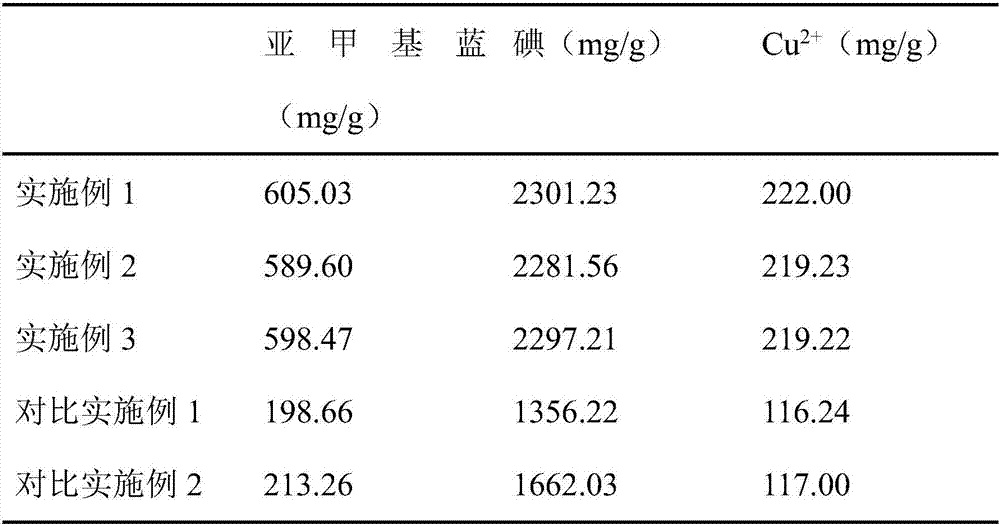

Examples

Embodiment 1

[0026] (1) After drying the edible fungus residue, pulverize it to 100-200 mesh; when drying, dry until the water content is less than 10%;

[0027] (2) According to the mass ratio of 1:5, the resultant of step (1) is mixed evenly in the activator aqueous solution of 30g / 100ml, immersed at 30~40℃ for not less than 20 hours, and after filtration, the filter cake is dried , activated at 750°C for 4.5 hours under nitrogen atmosphere;

[0028] (3) Cool to room temperature, pickle with dilute hydrochloric acid, then wash with water to neutrality, and obtain after drying; when drying, dry until the water content is less than 10%

[0029] The activator is composed of sodium hydroxide, potassium hydroxide and potassium carbonate in a weight ratio of 2:1:5.

Embodiment 2

[0031] (1) After drying the edible fungus residue, pulverize it to 100-200 mesh; when drying, dry until the water content is less than 10%;

[0032] (2) According to the mass ratio of 1:6, the resultant of step (1) is mixed evenly in the activator aqueous solution of 25g / 100ml, immersed at 30~40°C for not less than 20 hours, and after filtration, the filter cake is dried , activated at 750°C for 4.5 hours under nitrogen atmosphere;

[0033] (3) Cool to room temperature, pickle with dilute hydrochloric acid, then wash with water to neutrality, and obtain after drying; when drying, dry until the water content is less than 10%

[0034] The activator is composed of sodium hydroxide, potassium hydroxide and potassium carbonate in a weight ratio of 2:1:5.

Embodiment 3

[0036] (1) After drying the edible fungus residue, pulverize it to 100-200 mesh; when drying, dry until the water content is less than 10%;

[0037] (2) According to the mass ratio of 1:5.5, the obtained product of step (1) is mixed evenly in 28g / 100ml of activator aqueous solution, soaked at 30~40°C for not less than 20 hours, and after filtration, the filter cake is dried , activated at 750°C for 4.5 hours under nitrogen atmosphere;

[0038] (3) Cool to room temperature, pickle with dilute hydrochloric acid, then wash with water to neutrality, and obtain after drying; when drying, dry until the water content is less than 10%

[0039] The activator is composed of sodium hydroxide, potassium hydroxide and potassium carbonate in a weight ratio of 2:1:5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption | aaaaa | aaaaa |

| adsorption | aaaaa | aaaaa |

| adsorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com