Method for fermentation production of L-lactic acid by using surface immobilization technology

An immobilization, lactic acid technology, applied in the field of bioengineering, can solve the problems of low L-lactic acid fermentation yield, etc., achieve high economical value, increase cell density, and reduce the effect of substrate inhibition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

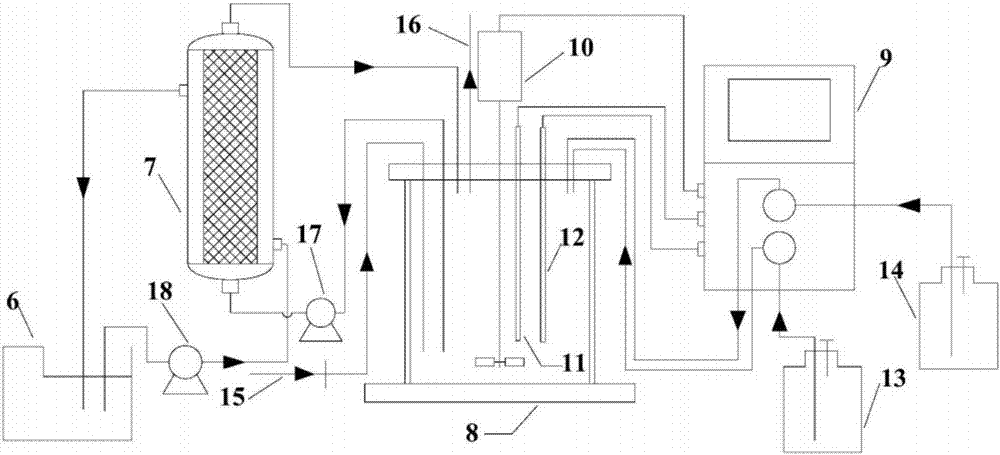

[0039] In this example, cornstarch is used as raw material, and the feed form of synchronous saccharification and fermentation is used for immobilization and repeated batch fermentation. The method steps are as follows:

[0040]Plate medium (g / L): glucose 5g / L, yeast extract 3g / L, peptone 10g / L, beef extract 3g / L, magnesium sulfate heptahydrate 0.5g / L, calcium carbonate 3g / L;

[0041] Fermentation medium (g / L): cornstarch 150g / L, yeast extract 15g / L, magnesium sulfate heptahydrate 0.5g / L, peptone 0.5g / L, anhydrous sodium acetate 3g / L.

[0042] (1) Plate culture: inoculate the frozen-preserved bacterial strains on the plate medium, and culture them statically at 50° C. for 48 hours in a constant temperature incubator to activate them.

[0043] (2) Seed culture: Pick bacteria from the activated plate and put them into 100ml seed culture medium, culture at 50°C and 100rpm for 24h to form a primary seed liquid. Then the primary seed solution was transferred to 500 ml of seed cult...

Embodiment 2

[0052] In this embodiment, immobilization and repeated batch fermentation are carried out in the form of single batch feeding, and the specific method steps are as follows:

[0053] Plate culture medium and seed culture medium are the same as embodiment 1.

[0054] Fermentation medium (g / L): glucose 150g / L, yeast extract 15g / L, magnesium sulfate heptahydrate 0.5g / L, peptone 0.5g / L, anhydrous sodium acetate 3g / L.

[0055] (1) plate culture: with embodiment 1;

[0056] (2) seed culture: with embodiment 1;

[0057] (3) Immobilized repeated batch fermentation:

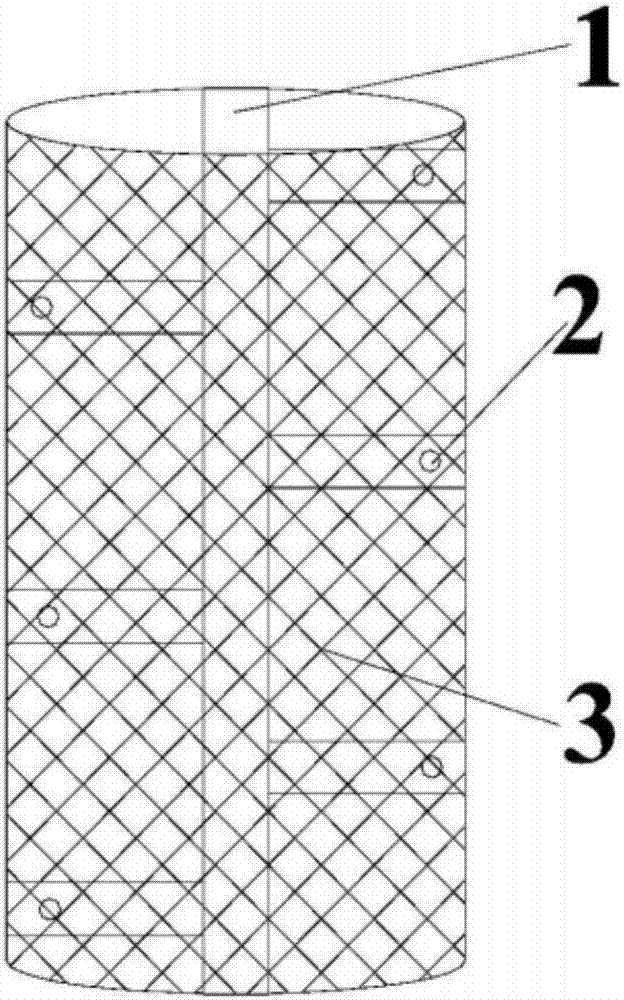

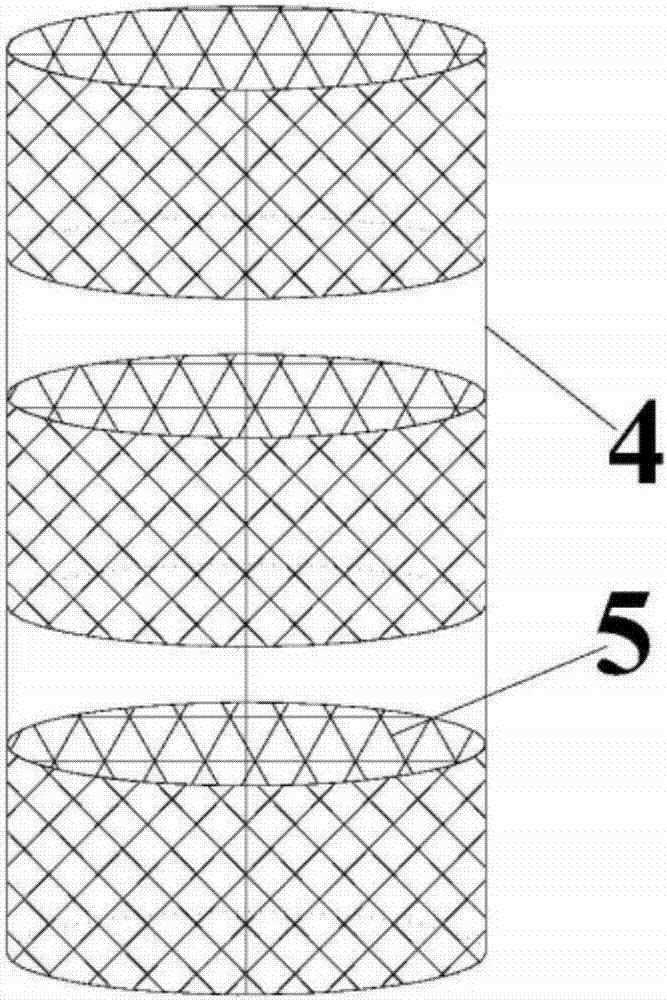

[0058] ①Construction of the immobilization reaction system: Fill the corncobs in the stainless steel bracket 4 with mesh grooves and put them into the jacketed stainless steel column to construct the immobilization reactor, and other steps are the same as the step ① of Example 1.

[0059] ② The immobilization process is the same as the step ③ in Example 1.

[0060] ③Repeated batch fermentation process: after the immobi...

Embodiment 3

[0065] In this embodiment, cornstarch hydrolyzed sugar solution is used as raw material, and immobilization and repeated batch fermentation are carried out in the form of fed batches. The specific method steps are as follows:

[0066] Plate medium and seed culture are the same as in Example 1.

[0067] Fermentation medium (g / L): 60 g / L of corn starch hydrolyzed sugar solution, 15 g / L of yeast extract, 0.5 g / L of magnesium sulfate heptahydrate, 0.5 g / L of peptone, and 3 g / L of anhydrous sodium acetate.

[0068] (1) plate culture: with embodiment 1;

[0069] (2) seed culture: with embodiment 1;

[0070] (3) Immobilized repeated batch fermentation:

[0071] ①Construction of the immobilization reaction system: fix the activated carbon fiber on the periphery of the stainless steel support and put it into a stainless steel column with a jacket to construct the immobilization reactor. The other steps are the same as the step ① of Example 1.

[0072] ②Pretreatment of fermentation m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com