Marine-weather-resistant powder coating containing graphene and preparation method thereof

A marine climate and powder coating technology, used in powder coatings, anti-corrosion coatings, polyester coatings, etc., can solve the problems of poor weather resistance and low production costs, and achieve low prices, large technology upgrades, and improved marine environment weather resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

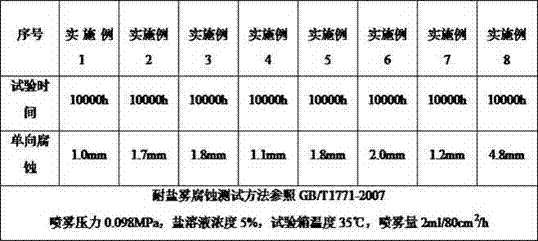

Examples

Embodiment 1

[0052] A graphene-containing marine climate-resistant powder coating, its raw material composition, by mass fraction, includes the following components: 60 parts of polyester resin, 4 parts of triglycidyl isocyanurate, 2.5 parts of graphene, flow 0.3 parts of leveling agent, 4.5 parts of matting agent, 0.1 part of catalyst, 1.2 parts of pigment carbon black, 9.9 parts of titanium dioxide, and 17.5 parts of filler.

[0053] Its preparation method comprises the following steps:

[0054] First, use an electronic balance to weigh the mass of each component in the raw material according to the ratio, mix evenly, and mix and stir at a high speed for 200-270 seconds until broken;

[0055] Then, it is heated at a high temperature of 90°C-110°C until it melts, cooled, pressed into tablets, crushed, and put into a mill to grind it into powder at high speed;

[0056] Finally, it is sieved and classified by a cyclone separator to obtain the finished product.

[0057] This embodiment is ...

Embodiment 2

[0059] The preparation method of this embodiment is basically the same as that of Example 1, and the technical effect achieved is also basically the same. The difference is that a kind of graphene-containing marine climate-resistant powder coating provided by this embodiment has a raw material composition, by mass fraction Calculated, including the following components: 80 parts of polyester resin, 6 parts of triglycidyl isocyanurate, 0.5 parts of graphene, 0.3 parts of leveling agent, 3.5 parts of matting agent, 0.1 part of catalyst, 1.2 parts of pigment carbon black, 5 parts of titanium dioxide, 3.4 parts of filler.

Embodiment 3

[0061]The preparation method of this embodiment is basically the same as that of Example 1, and the technical effect achieved is also basically the same. The difference is that a kind of graphene-containing marine climate-resistant powder coating provided by this embodiment has a raw material composition, by mass fraction Calculated, including the following components: 66 parts of polyester resin, 5.1 parts of triglycidyl isocyanurate, 3 parts of graphene, 0.3 parts of leveling agent, 5 parts of matting agent, 0.1 part of catalyst, 1.2 parts of pigment carbon black, 10 parts of titanium dioxide, 9.3 parts of filler.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com