Preparation method of guanidinated chitosan and application of guanidinated chitosan

A technology of chitosan and chitosan, which is applied in the field of functional polymer materials, can solve the problems affecting the inhibition of lysozyme, and achieve the effects of avoiding side reactions, good biocompatibility, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

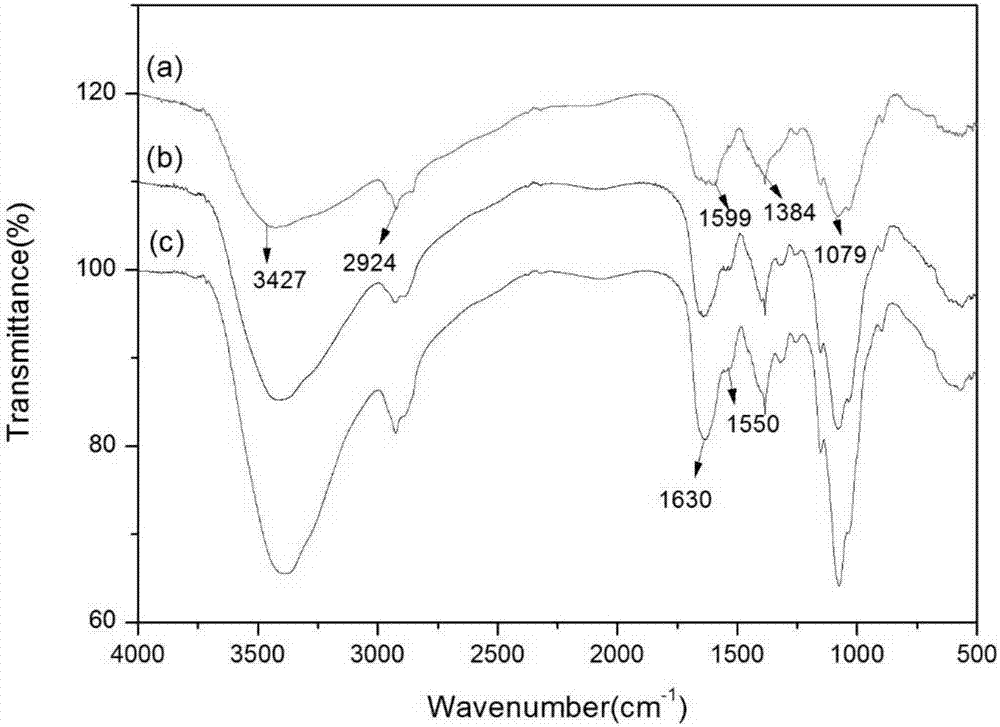

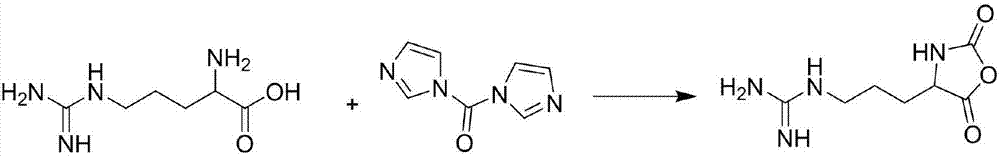

[0029] Weigh 2.0 g of arginine and 4.84 g of N,N'-carbonyldiimidazole, dissolve them in 50 mL of anhydrous methanol, and stir at 0-5°C for 3 hours to obtain carboxyl-activated arginine for use. Weigh 2.7g of chitosan (viscosity average molecular weight 15kDa, degree of deacetylation 90%) and dissolve it in 100mL MES aqueous solution, and then add the carboxyl activated arginine prepared in the previous step directly to the chitosan solution, and the addition is complete Then, it was stirred at room temperature for 6h. The solvent was removed under vacuum, and the product was dissolved in ultrapure water, dialyzed (MWCO 6000) for 3 to 4 days, and freeze-dried. The infrared spectrum of the prepared guanidyl chitosan GCS1 is as figure 1 As shown in (b), elemental analysis shows that the guanidine group grafting rate is 34.8%.

Embodiment 2

[0031] Weigh 1.9 g of arginine and 3.72 g of N,N'-carbonyldiimidazole, dissolve in 100 mL of anhydrous methanol, and stir at 25° C. for 6 hours to obtain carboxyl-activated arginine for use. Weigh 1.6 g of chitosan (viscosity average molecular weight 8kDa, degree of deacetylation 88%) and dissolve it in 100 mL of MES aqueous solution, and then add the carboxyl activated arginine prepared in the previous step directly to the chitosan solution. After the addition is complete , Stir at room temperature for 20h. The solvent is removed under vacuum, the product is dissolved in ultrapure water, dialyzed (MWCO 3400) for 3 to 4 days, and freeze-dried. The infrared spectrum of the prepared guanidyl chitosan GCS2 is as figure 1 As shown in (c), elemental analysis shows that the guanidine group grafting rate is 45.2%.

Embodiment 3

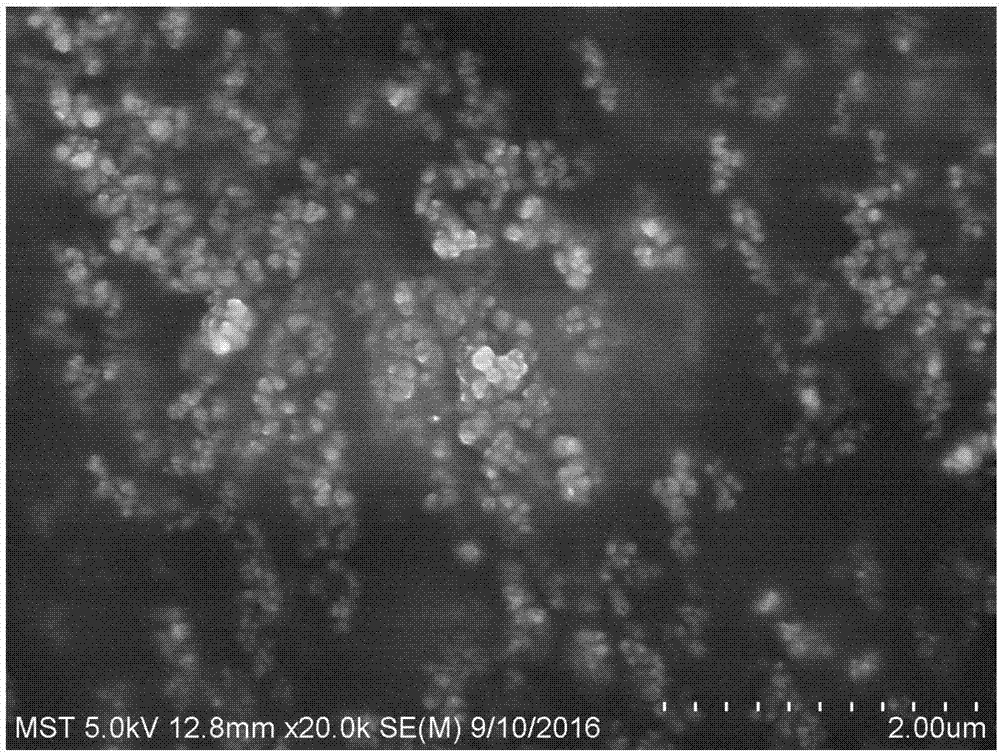

[0033] An aqueous solution of guanidinated chitosan (viscosity average molecular weight 15kDa, guanidine grafting rate 34.8%) containing lysozyme was prepared, wherein the concentration of lysozyme was 1 mg / mL and the concentration of guanidinated chitosan was 1 mg / mL. Prepare 2mg / mL dextran sulfate aqueous solution. Using 2mL dextran sulfate as the base solution, use a syringe pump to add 0.8mL of guanidinated chitosan solution containing lysozyme at a rate of 10mL / h. The stirring speed of the base solution is 500rpm. Continue stirring after the addition is complete 10min. Settling naturally overnight, centrifuging at 4°C (rate 5000xg) for 20 minutes, removing the lower layer of precipitation, and freeze-drying to obtain antibacterial nanospheres. The lysozyme encapsulation rate of the nano microspheres is 45.78%, and the drug loading rate is 27.62%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com