Pulse xenon lamp and sealing method of the same

A pulsed xenon lamp and adapter technology, used in the manufacture of discharge lamps, gas discharge lamps, discharge tubes/lamps, etc., can solve the problems of relying on labor, small load current, complex sealing process, etc., to achieve service life and reliable work The effect of improved performance, good vacuum sealing performance and high structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

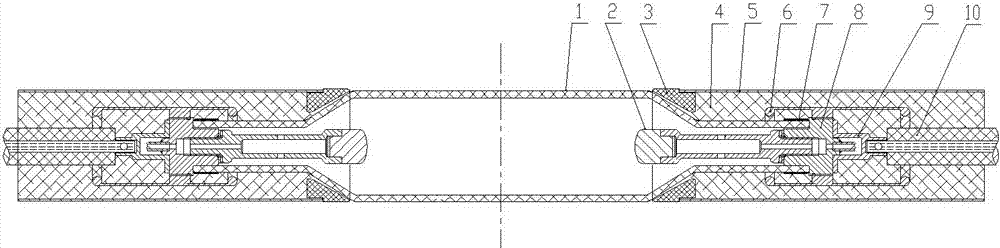

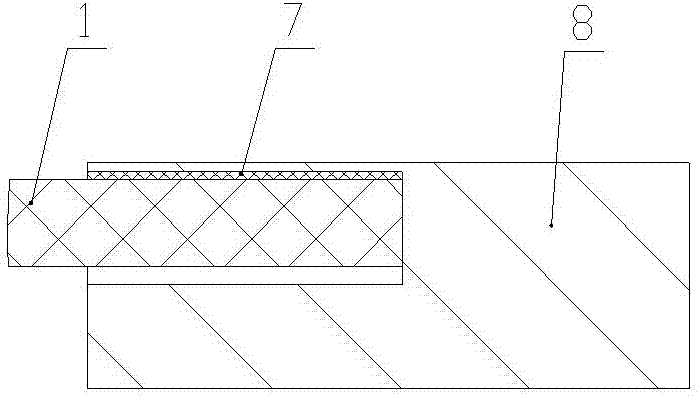

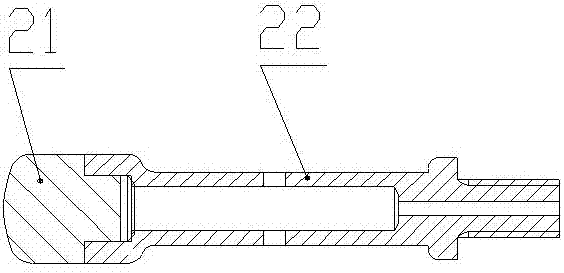

[0031] figure 1 It is a sectional view of the pulsed xenon lamp of the present invention, figure 2 for figure 1 The schematic diagram of the local structure in , that is, the schematic diagram of the structure of the electrode cap and the sealing area of the quartz tube, image 3 It is a schematic diagram of the electrode structure in the present invention. exist Figure 1~Figure 3 Among them, the pulsed xenon lamp of the present invention has a cylindrical symmetrical structure, and the pulsed xenon lamp includes a quartz tube 1, an electrode 2, a ceramic ring 3, an insulating glue 4, a stainless steel sleeve 5, a pressure equalizing cap 6, an active solder 7, Electrode cap 8, adapter 9 and cable 10. The connection relationship is that the two ends of the quartz tube 1 are respectively provided with electrode I2 and electrode II along the transverse central axis. Electrode I2 and electrode II are symmetrically arranged along the longitudinal central axis of quartz tub...

Embodiment 2

[0043] This embodiment has the same structure as Embodiment 1, except that the distance between the electrode I2 and the end of the electrode II is 440mm; the outer diameter of the quartz tube 1 is 37mm;

[0044] The material of the electrode head 21 is multi-component composite tungsten alloy, and the material of the electrode rod 22 is molybdenum.

Embodiment 3

[0046] The structure of this embodiment is the same as that of Embodiment 1, except that the distance between the electrode I2 and the end of the electrode II is 200 mm; the outer diameter of the quartz tube 1 is 22 mm; the wall thickness of the port of the quartz tube 1 is 2 mm ;

[0047] The material of the electrode tip 21 is yttrium tungsten, and the material of the electrode rod 22 is niobium.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com