Polarization chamber system based on hyperpolarization gas and use method thereof

A hyperpolarization, cavity technology, applied in applications, medical science, sensors, etc., can solve the problems of difficult operation, non-recycling, gas waste, etc., and achieve the effect of simplifying operation steps and reducing waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The following is a detailed description of the embodiments of the present invention. This embodiment is implemented on the premise of the technical solution of the present invention, and provides detailed implementation and specific operation process, but the protection scope of the present invention is not limited to the following the embodiment.

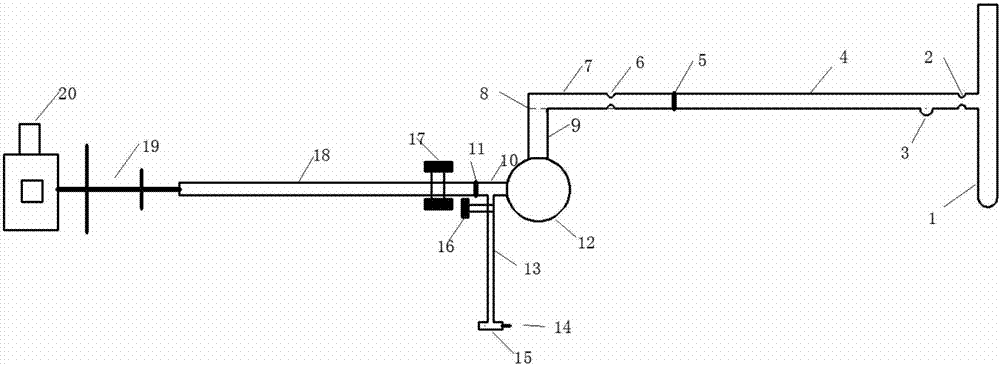

[0041] Such as figure 1 As shown, the present invention discloses a polarized chamber system based on hyperpolarized gas, including an alkali metal retort 1, a polarized chamber 12 and a gas flow meter 20; an alkali metal retort 1 and a polarized chamber 12 They are connected through the first pipeline, and the polarization chamber 12 and the gas flow meter 20 are connected through the second pipeline.

[0042] The first pipeline is composed of the first high borosilicate glass branch pipe 4 and the GE180 glass branch pipe fixedly connected, and the junction of the first borosilicate glass branch pipe 4 and the GE180 glass ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com