A Repairing Structure and Construction Method of Expansion Joint Transition Area of Expressway Concrete Bridge

A technology for expressways and repair structures, applied in bridges, bridge materials, bridge construction, etc., can solve the problems of poor fatigue impact resistance, fatigue fracture, fracture toughness and impact resistance, etc., and achieve high impact resistance and durability Excellent performance, improved fracture toughness and impact resistance, and improved overall stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

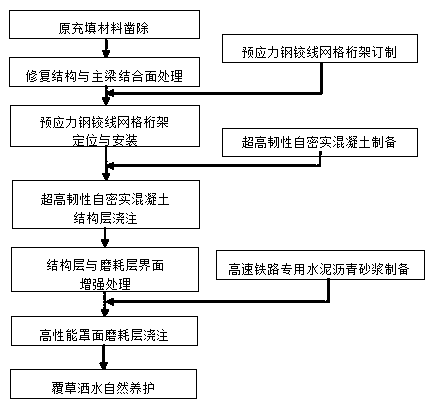

[0033] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

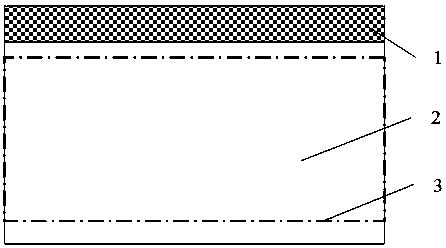

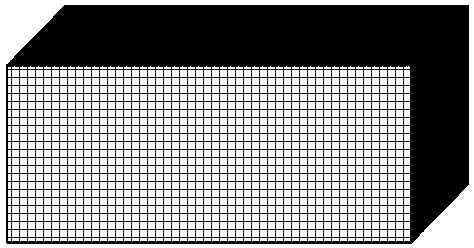

[0034] Such as figure 1 As shown, a repair structure for the transition zone of the expansion joint of a highway concrete bridge is composed of a high-performance overlay wear layer 1 and an ultra-high toughness self-compacting concrete layer 2, and the ultra-high toughness self-compacting concrete layer 2 is equipped with prestressed steel strands The truss 3 and the high-performance overlay wear layer 1 are covered on the super-high toughness self-compacting concrete layer 2 .

[0035] The high-performance overlay wear layer 1 is poured with cement-asphalt mortar special for high-speed railways, and the pouring thickness is 5.0-8.0 cm. The cement-asphalt mortar for high-speed railway can use any type of cement-asphalt mortar for high-speed railway on the market. During the implementation process, DRX-H10 cement-asphalt mortar and DRX-H12 cement-aspha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com